Transfering a ’34 Ford body onto a modern TCI chassis

By Steve Temple

Photos by Steve Temple and Lee Ercoline

At first glance, mounting a street rod body on a frame might sound fairly simple. With a little help from your friends, just lower the cab down gently, and then bolt it place, right? Well, yes and no. As with so many buildup projects, it turns out that there’s more to it than meets the eye.

To find out more, we sought out some tech tips from the crew a Full Circle Restorations, in the process of replacing the chassis on an original ’34 Ford owned by Lee Ercoline. The old frame was a bit rusty in spots, but even worse, the suspension had been lowered incorrectly by a different shop, so the ride quality was poor, and the steering rack was hitting the shock.

What made this job even more complicated was the fact that the body had already been painted, so it had to be handled with care. It’s also made of metal, rather than fiberglass, so it was heavier. Plus, the interior and glass were already installed.

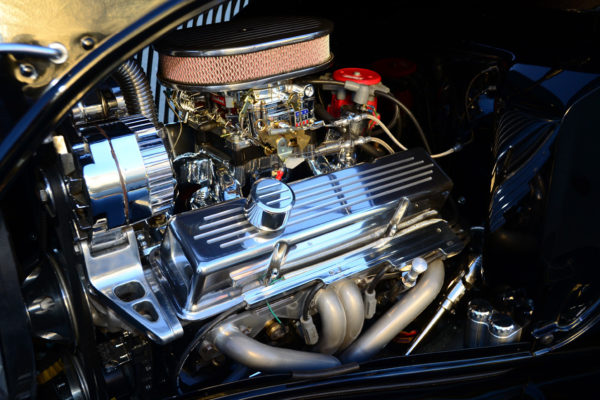

Not only that, prior to refitting the body on a modern TCI chassis, the firewall and floorpan had to be modified

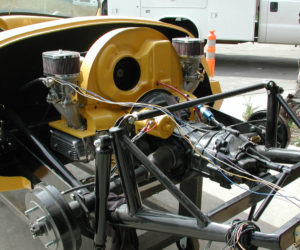

to make room for the V-8 engine being set back farther on the frame for better balance and more clearance up front. (Even so, the water pump clears the radiator by only a fraction of an inch.)

In addition, the pumpkin on the live axle rearend was too close to the floorpan, so that required correction as well. Fortunately, Direct Sheetmetal supplied a floor kit that makes room for a bigger Third Member, along with a recessed firewall that clears a small-block V-8.

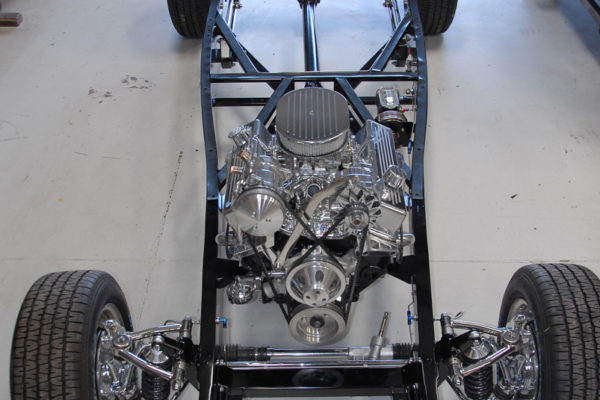

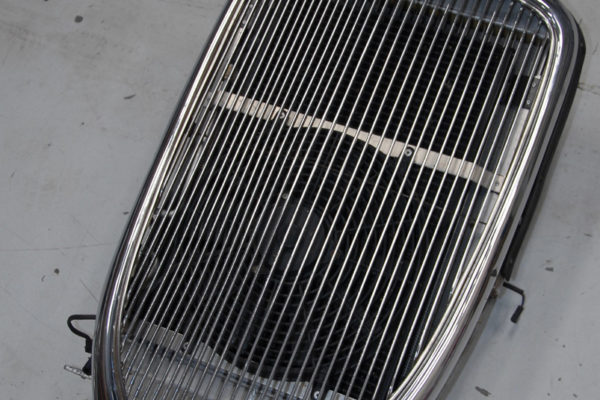

All this cutting and splicing on the body are worth the extra effort, however, because the TCI chassis improves on the original setup in a number of ways, while maintaining the correct body mounting locations. This company’s 1933-‘34 frames feature full-length, boxed rails (instead of the flimsier C-channel used back in 1934), plus rectangular X-members for strength and rigidity. It’s available with either a stock-style front crossmember with a a one-inch drop, or an IFS front crossmember, and a choice of three different rear crossmembers.

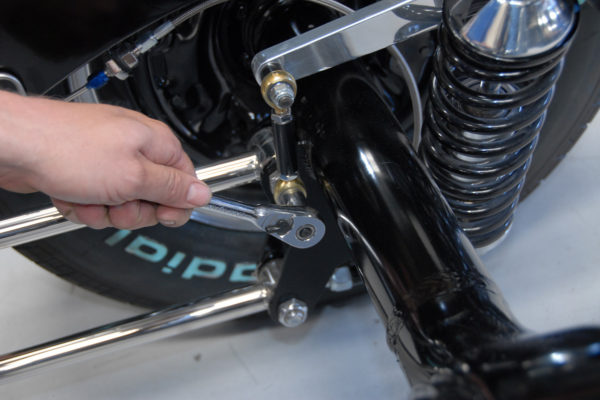

On this particular vehicle, the fronts have dual A- arms with coilovers and an adjustable swaybar. At the rear is a parallel four-bar setup with a Panhard rod (rather than triangulated upper control arms). Lee also opted for some swanky-looking polished control arms and the extra stopping power of Wilwood brakes. He points out that the TCI frame comes on a pallet, with the suspension components all neatly boxed and ready for installation.

Bolting the whole thing together is fairly simple matter, notes Tom Van Steyn of Full Circle Restorations. (Well, at least some things went easy on this project.)

While this part was being handled, Van Steyn also welded in the new firewall and fabricated a stronger mount for the Ididit steering column. Besides being sturdier due to having a big flange, it also seals up the hole in the firewall (which keeps out mice looking to make a nest, which can be a problem at times).

Prior to mounting the body, Van Steyn dry-fitted and then glued down strips of rubber to the frame rails using 3M contact cement. He prefers using the type of strips with webbing in the middle, since they’re stronger and last longer. No reason to skimp here.

Once Van Steyn and his burly crew hefted the body on the frame, it fit like the two had been made for each other. Well, it did take a bit of gentle persuasion to line up the mounting holes, but once that was done, the body bolts snugged right down.

Now Lee has a ’34 Ford that rides smooth, handles right and puts the power to the ground. And no squeaks from rubbing parts or curious mice. Now that’s the kind of body talk we like to hear!

Comments for: BODY TALK

comments powered by Disqus