1962 Corvette

Text and Photos by Steve Temple

Ward Seifrid’s ’62 Corvette started out as a complete basket case, literally a pile of parts stored in the second-story rafters of a commercial building. Despite its dilapidated condition, with a frame in such bad shape that it was not salvageable, “I bought it anyway, primarily because it was titled,” he admits.

Initially Seifrid considered doing a pure resto, since he has a few other collectible Sixties Corvettes in his collection. So he had some initial assembly work done on the car by a restorer, but then took it to John Wargo of The Custom Shop. After several discussions to develop all the details, and seeing Wargo’s numerous other restomods, he completely changed his mind: “Everything just kind of came together—I wanted to step it up a notch from the others.”

That’s really an understatement, since the concept and list of upgrades they came up with was not merely extensive, it was exhaustive. Virtually every single component would be breathed on, massaged, or manipulated. Seifrid immediately began sourcing the hopped-up engine and contemporary chassis components to bring them all together for this two-year project.

Before installing the suspension parts (note sidebar), however, Wargo and his crew lavished attention on the frame welds, all smoothed, finish sanded, and then primered and sanded again, and then painted the body color. Panels made of machine-turned stainless steel reinforce the cockpit floorboards and provide sound/heat insulation, along with a layer of Hushmat.

All this extra effort to modernize and beef up the chassis was entirely warranted, given the engine: a Dart M iron big-block that boasts a grand total of 598 supercharged cubes delivering more than a grand worth of horsepower. It’s topped by aluminum Dart 355 Pro 1 heads and a ported Edelbrock Super Victor intake, and supercharged by a Vortech YSi centrifugal blower.

Commenting on why he chose this setup, Seifrid says, “I wanted to be over 1000hp, but still use pump gas. I didn’t want to have to mix fuels and use race gas as well.” Pulls on the dynohave gone as high as 1086 hp, which will require an eventual upgrade to a triple-disc clutch to eliminate slippage.

Fast Times Motorworks built this Chevy rat motor, fitting it with a Scat 4340 forged-steel crank (4.500-inch stroke) and H-beam rods pumping JE pistons. The slugs are dished to compensate for the forced induction, with a 9.0:1 compression ratio. The Manley valvetrain components are actuated by COMP cams roller lifters, and a custom-ground bumpstick.

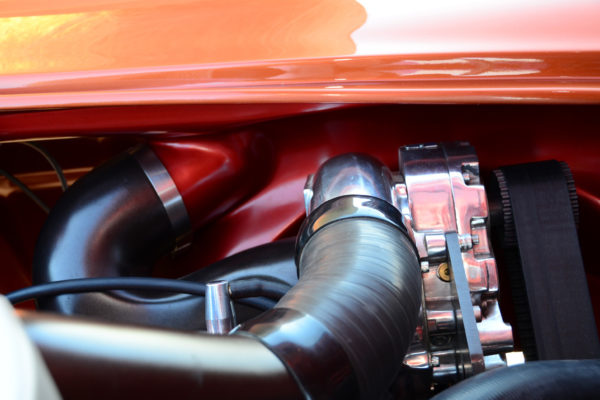

A Holley Terminator EFI system controls four 125-pound injectors (think garden-hose size) to keep up with the blow-through airflow from the Vortech centrifugal supercharger. (Wargo says it was the first one ever done by Holley using a carb-style throttle body.) Given the engine’s substantial displacement, it only needs nine pounds of boost to exceed 1000 horses. Twin fuel pumps feed the beast, and second one kicks in when the boost comes on. Custom headers and a Borla exhaust system vent the spent gasses.

Dress-up items include Billet Specialties valve covers, and an artfully crafted custom air cleaner fitted with a K&N filter element. Keeping this hot mill from boiling over is a Spal fan fitted to a custom-fabricated radiator that’s 50 percent thicker. Other accessories include an electric water pump and a Tuff Stuff alternator. A billet shifter actuates the Bowler Performance Tremec TKO 600.

The hood is motorized and features a raised center section with vents on the sides. Other exterior modifications include bumpers tucked and molded into the body, and finished in satin silver. The grille is a custom 3D insert, fabricated by Wargo’s shop. The headlights are LED, and the projector fog lights have Halo rings. The taillights are modified Lexus units, and the third brake light is a custom-molded piece.

The Copper Topless logo appears in several places: dash, horn button, trunk interior, door sills and rear emblem. Both the floorboards and trunk have metal rub strips, and the interior of the trunk is as nicely finished as the cockpit. The list of detail work goes on and on.

What was the most challenging aspect of the buildup? “Fitting so much motor and supercharger under the hood,” Wargo admits. “And installing so many electronics in the car and still hiding all the wires. That, and making the fit and finish as good as it is.”

There may be even more challenges ahead of him, though, as Seifrid would like to do a mid-engine Corvette that’s even more radical, yet could still be put back into original condition. So he’s currently on the lookout for another C1 that’s beyond repair.

By the way, how did the name “Copper Topless” come about? “I’d call it anything, but Wargo came up with the name,” Seifrid says. “He’s very creative. I have 1000 percent confidence in him. I couldn’t find a better guy to work with.”

All told, Copper Topless is one bad penny that turned out to be precious metal. And you can take that to the bank.

Comments for: COPPER TOPLESS

comments powered by Disqus