Factory Five's all-steel ’33 Hot Rod

Story and photos by Steve Temple

Ford’s early history is marked by several key models. Obviously the Model T was its first success, introduced in 1908 after years of development to create the first everyman automobile. Henry’s son, Edsel, was influential in bringing forth the updated Model A in late 1927. And in 1932, the introduction of the new flathead V8 was especially noteworthy, a hugely important milestone in U.S. automotive history.

Then the Model 40 came out in early February 1933, with substantial revisions in the car’s styling. The ’33 Ford had a 6-inch-longer wheelbase, and the appearance changed significantly with a sloped, shovel-shaped grille. Streamlining was accentuated by the hood covering the cowl, along with more rounded and skirted fenders and bowed bumpers. Many other subtle changes enhanced the design, and to this day, the ’33 Ford (and the slightly different ‘34 model) are widely replicated.

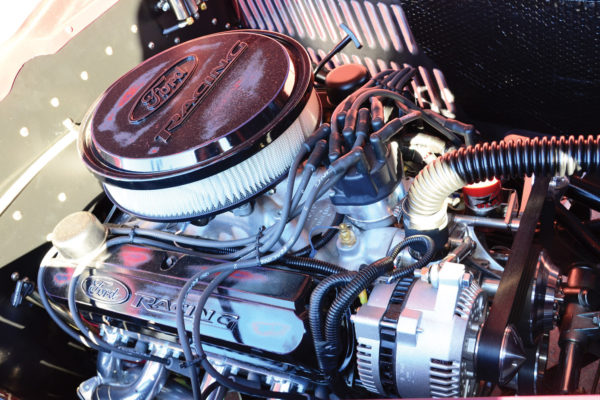

Which leads us the Factory Five Racing ’33 Ford. The company made quite a splash in the street rod market when it introduced a much more modern chassis. Instead of just the two straight longitudinal members used on the original, the frame is triangulated for much more rigidity, not only for a more stable geometry, but also to handle V8 engines many times more powerful than the original.

In addition, the suspension components include mounts for either a three- or four-link setup, or an IRS, rather than a stiff, old-school straight axle. At the front, inboard-mounted, adjustable coilover shocks and tubular control arms with ball joints make for much more sophisticated handling and control, along with modern Mustang brakes.

More recently, FFR is making yet another significant change, but one that looks to the past instead of ahead. While the majority of replicas employ fiberglass or aluminum bodies for their ease of manufacture and lower cost, some die-hard rodders want a body made of steel, just like Henry made.

How did FFR bring about this new option? “Basically, we scanned our glass body,” explains FFR’s Jim Schenck. “And made some changes and updates we have been wanting to make, as well as some things needed for the stampings, and then had the large dies made for the main body, the hood, trunk and doors.”

Easier said than done, of course, as all of FFR’s other vehicles are still made of fiberglass, and a steel body is a much different approach. The all-steel body comes complete with all panels including hood and louvered front engine covers. The parts are delivered E-coated (in any color you want, w). They require no panel trimming or fitment, minimizing the amount of bodywork needed. The steel thickness ranges from 19- to 21-gauge steel, depending on the panel. Currently, the plan is to offer the bodies as a $10k option above the fiberglass, but with the bodywork already done and the bodies in primer. This is still a project in the works, yet should be nearly done by the time you read this issue.

We built a very quick prototype for SEMA last year,” Schenck notes. “And then built a complete car out at the Barrett Jackson show in January.” The goal is to have production bodies ready to ship before the end of the year. If Henry were alive today, he’d be nodding in approval. And probably getting mass production moving along too!

Comments for: Hot Tin Roof

comments powered by Disqus