CBR1000RR-powered ’27 Ford hot rod

As told by Dave Green

Photos by Steve Temple

Who says a rod has to have the engine up front? Or even one from a car? Rules are made to be broken, so that’s what I did with my Honda-powered ’27 roadster.

Cars inspired me from a young age, and it all started with a slot car I built when I was 4. Since then, I’ve been designing and building cars, motorcycles and go-karts nonstop. I have also always appreciated high-revving motorcycle engines, and about 15 years ago, I restored and then modified a 1972 D Sports racer with a Honda CB750-4 for track days and autocross.

This ’27 roadster project started out as a replacement for my 1972 D Sports racer. It would be in part a tribute to my dad’s hotrodding heritage from the 1950s, combined with my desire for more horsepower and higher revs.

I had been autocross-racing my B-Mod D Sports racer for five or six years, and the 700-pound car was extremely quick with a Kawasaki ZX-9R 900 cc engine installed. But it only had one seat, so no one was ever able to ride along to share in the experience. Part of my motivation for building the roadster was to be able to have a second to share in the joy.

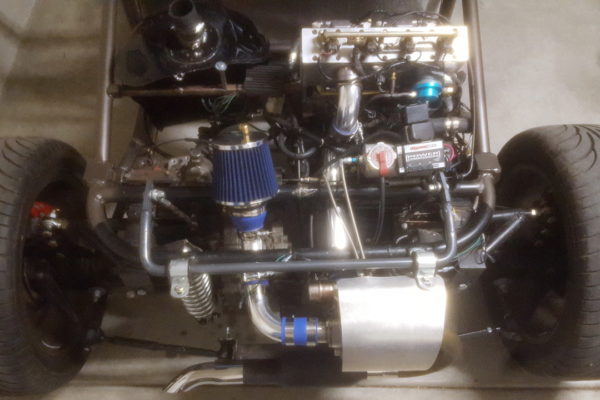

The car started out as a vintage road-race car with a Speedway Motors Track-T body but soon evolved into a street-legal hot rod with a midmounted engine. My original design for the car, however, had the Honda CBR1000RR motorcycle engine mounted in the front, with a driveline running under the passenger seat to a Suzuki Samurai rear axle. It came together in about four months, and I drove the car that way for about two years. But I was never able to find a locking or limited-slip differential for the Samurai axle. So I then cut everything back to the frame and essentially rebuilt the car. I ended up reconfiguring it as a midengine racer with a 1993 Toyota Turbo MR2 rear transaxle. This second build took another six months.

I initially set the car up to utilize the motorcycle’s transmission and shifter, but eventually installed the Toyota shift linkage. That allowed me to leave the motorcycle transmission in sixth gear and, using the motorcycle’s clutch, drive the car with the five-speed Toyota transaxle. And also there’s that small matter of a reverse gear for street driving.

The car is comprised of several different manufacturers’ components that were specifically selected for their unique W A custom turbo manifold for the Honda 1,000 cc motorcycle engine fits under the right rear quarter of the Speedway Motors Track-T body. A ’93 Toyota MR2 provided the transaxle. Honda-powered ’27 Roadster Readers’ Rides The custom tubular frame carries a wide range of components, from a Volkswagen torsion bar front end to a Toyota MR2 rear suspension dampened with QA1 coilover shocks. capabilities. I chose the Honda CBR1000RR motor for its advanced rotating mass design and computerized fuel injection system — plus the fact that it has a second set of fuel injectors that kick in at 5,000 rpm and shoot straight down the throttle bodies.

Together with the T25 turbocharger coming online at about 4,800 rpm, the motor’s power band is like a two-stroke dirt bike. In fifth gear, the engine is turning about 4,000 rpm at 65 mph, and the redline is 12,000 rpm. Peaky!

I went with the Toyota Turbo MR2 transaxle because it had a factory limitedslip differential and was configured with a right-side input shaft. That allowed me to mate it to the left-side output shaft on the Honda motorcycle engine. I fabricated an adapter between the Honda engine and the Toyota transaxle that utilized a rubber donut universal joint from a Formula Ford to reduce the shock on the motorcycle engine’s drivetrain.

Up front, I selected a 1968 Volkswagen torsion bar suspension for its simplicity, strength and adjustability. The steering system consists of a 2003 Boxster rack-andpinion setup with Mitsubishi tie rod ends. The Porsche’s rack provides great handling and a quick turning ratio, and it was easy to adapt to the VW front suspension.

But, of course, all these components need a strong foundation, and my roadster is based on a triangulated space frame constructed from 1.5-inch DOM steel tubing. Brakes are Wilwood up front and Toyota in the rear. The adjustable shocks in the rear are from QA1.

On all of the projects I have built since this one, the primary design work was completed using AutoCAD design software. This one, however, was built the old-fashioned way with a flat concrete floor, tubing bender, MIG welder and tape measure.

The frame dimensions are primarily based on the fact that the body is narrower at the bottom than it is at the top, and the entire frame and roll bar would need to fit within the body footprint. Using the fiberglass body as a template, I made a bottom frame section out of 2-by-2-inch square-tube steel. I then mocked up the seats and took measurements for the overall height of the roll bar and for the three other vertical hoops under the dash, at the firewall and the radiator support. I then used a series of top bars and diagonal supports to create a triangulated space frame.

The front of the frame was constructed to mimic how Formula Vees have been set up for decades, and the rear was designed to accept the inboard-mounted coilover shocks and midengine configuration. Originally I had envisioned having the body mounted on some sort of hinge system that would allow me to raise the body in the pits like a Funny Car dragster, but I haven’t gotten to that yet.

After 18 months of work spread out over 10 years, I finally completed the car. With 220 horses on tap in a car that weighs only 1,160 pounds, it’s quick and tossable, hitting 60 mph in just 4.5 seconds and ripping through the quarter-mile in 12 ticks. I’m able to autocross it with abandon, usually about 10 times every year.

I call this car Red Blend, not only because of its rich Viper red paint job, but also for the many manufacturers’ parts that went into it. I selected each piece for its unique qualities, blended like a fine wine with flavor that’s greater than the sum of its parts.

Comments for: Red Blend

comments powered by Disqus