Buildup of a GTM Supercar

As Told by Gene Bowling

Photos by Steve Temple

How did I decide to build a Factory Five GTM? I was bored one Sunday in January, and saw a ‘33 hot rod being assembled on the TV show 2 Guys Garage. I went to the Factory Five web page and fell in love with the GTM. From there I began to read the forum builds. I knew I had found a dream.

Frankly speaking, the kit is a challenging build, with a lot of hurdles that hang up guys from finishing it. All I had to do was overcome these things, and I would have a supercar. I’m in! When I began this venture, it took about a year to first complete a new garage, and sell one of my cars to fund the kit. I got it new from Factory Five, shipped from the East coast to Washington state. It arrived as I was putting the shingles on the new garage.

Before getting into the build story, I should mention a bit about my background, since this project goes back to my childhood roots. Seems like I was just born to work on things. I remember in grade school, taking my bike apart to paint it. I recall clear back then how picky I was (which carried through on my GTM as well). I stripped it down to paint, realizing that if I didn’t take certain things off, like the bearing race for the gooseneck, it would look like someone painted it at home. So I figured out how to get them off, without ruining them, paint the frame, put them back on, and now it looked like the factory did it.

I grew up without my dad around, but when I got old enough, I’d spend summers with him. He was a car-body man, and I worked for him learning the trade. I got out of school, and started learning bodywork full time. My dad opened a shop and we worked together for a few years. One morning he went with a customer to pick up a car and never came back. He died in a car crash, not his fault.

I learned some important points from him, though, before he passed away. One of the best things my dad ever taught me was when I was pulling the bumper off an old Cadillac, back when we called them two-man bumpers. That’s because it took two men to get them off.

I could not get the rusty bolts to come off, so I went and told him that I can’t get it done. Giving me a pissed-off look, he said, “If you can’t do it, someone else will!” So I went back, got it off, and to this day, you will never hear me say, “I can’t do that!” (That holds true on my GTM, as you’ll see.)

I became one of the best body men in town, doing journeymen collision work for years. One other thing my dad told me: “If you ever get into this business, I’ll kick your ass.” I asked why, and he said, “Have you ever seen a retired body man?” I said,”No.”

I had the opportunity to change careers, and I did. I now am a hearing aid fitter/dispenser. This profession has set up a scenario that now allows me to work on cars at home, for fun. My problem, however, is that I end up getting into builds that consume me. I now need to balance life with my obsession—no more four-year long builds without coming up for air! Thank God I have a good wife that puts up with me.

Getting back to the build of my GTM, when I started to work on the car, I had no money. But man, I wanted to start. Of course I read the manual two or three times, and checked out all my parts. By the way, I knew right from the start I was not going to be following the manual. Don’t get me wrong, I’m not dissing a donor-car build, I just knew that is not how I was going to do it. I wanted everything to have a legit spot, all wires to be routed nicely, clean and simple, and everything serviceable.

The GTM is designed to use parts from a C5 (or C6) Corvette. Since my car was not a donor build, I did not want any used parts in what I knew was going to become a supercar. I did pull some parts from eBay, such as control arms, steering column, E-brake, and engine. I think those are all that are used on the car, and everything else is new. The new C5 parts include the radiator, AC Delco big-brake kit, and custom fuel tanks.

As for all the used parts, I made them clean and new. One thing I like to do on the bare aluminum is put a coat of clear on it; that way it does not get corroded and seems to hold up well with a car that hardly gets driven.

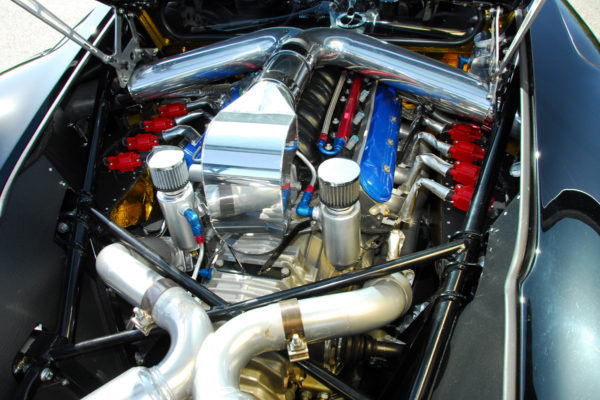

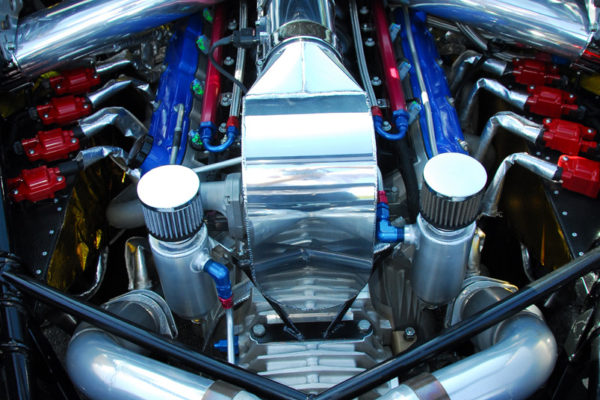

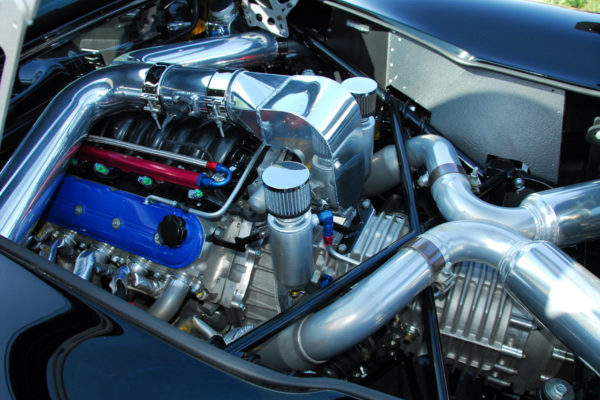

The other big story in this part is the LS2. I got it from eBay, described new and fresh, but it was a mess. That’s the excuse I needed to rebuild it. I added a Trick Flow top end and custom intake from Spectre Performance, resulting in 440 horses to the wheels. Mendeola’s SDR-5 transaxle divvies up the powerband.

During the nearly four years of building my GTM, the Factory Five forum members were a lot of help. There are a couple of vendors posted on there that produce some must-have parts. I love the forum community; none of us are as smart as all of us. With those guys, the pains of others are passed down, so we don’t all have to find out the hard way!

Since the car is designed around the LS motor, much of the car is already setup right, no mods needed. Any deviation from stock is with electronics, chassis harness, and in-car entertainment. Well, I did put a Race Logic Traction control in it, which took a lot of research to get it going. I had a run-in with a U.S. vendor, and called the company in UK, which graciously helped me out.

While I’m leaving out many details about the research that I spent building this car, I did assemble the kit entirely by myself, in my garage. Many, many people know every little detail, every little step I took, from start to finish. I did something kind of daring with this build: I filmed the whole thing from start to finish, the good and the bad, bright spots and blemishes, for all to see. I have a Youtube channel called fastthings, and a folder with 80 videos spanning nearly four years. (Go to Youtube search “fastthings” and you will find my channel.) I update it with what I’m up to, and now have more than 1700 subscribers.

As on most project cars, one of the major problems is the body work. It’s such a huge challenge, that a lot of guys give up and sell their project in midstream. It’s one thing to get the doors to close, the windows to roll all the way down. But man, the body doesn’t even set on the chassis square. Guys were finishing the cars, and you would look at the rear and see one tire sticking out and the other tucked in. There are many ways to skin a cat, and many guys did different things to fix it and look good.

Initially, the only thing I could do to the car was the body work, even though most do this at the end. And shoot, why not get the mess out of the way before all the new stuff is bolted on? I had no money to buy any parts to begin putting the chassis together. So I set the car on a level pad, started finding symmetrical points on the car. Then set the body on with the same concept.

I knew it would come out perfect in the end, because I have spent years measuring, and pulling cars in collision work. Then I put the first video out there. People cautiously watched, concerned I was making a big mistake, doing things in the order I was. I explained why I was doing it that way and if it was wrong, all would see. I promised to show it all, good, bad and ugly.

It turned out to be such a fun thing, all the way through video #80. I got so many compliments, words of encouragement. It was inspiring, and at the same time I was inspiring others. We fed off each other, and often someone would warn me of a mistake. It’s not all fun and games; you see real emotion as I build, guys encouraging me. It was awesome.

A couple forum guys got really mad, claiming that if that’s what they have to do to make this car look good, they would never buy one. I’m thinking to myself, good! Like Factory Five’s Dave Smith says, “These kits are a test.” You’ll never know what he is talking about unless you finish one. It’s not just a test of skills. I could not have done this without so many things staying perfect for four years, it’s hard. Life happens in four years.

Getting down to the nitty-gritty of the bodywork, I would get up at 4:30 a.m. and work, before my day job, and then after work, and then 20 some hours on the weekend. Nothing lined up, nothing was symmetrical. Both doors are different thicknesses, and it causes different issues aligning them, and getting the windows to go up, down, and to seal. A lot of work on the hood, getting it to fit. It’s sickening to think how much I put into the bodywork, but worth it in the end. And I knew what I was getting into.

If you are really interested in all that went into it, watch the videos, you’ll get sick of my voice, lol. I basically finished the entire body, windows in, all doors hinged and latched, lights, mirrors. Put it all in primer, ready for paint. Pulled it all apart and put it away. I would not look at it for about another year or so.

Most car builders finish the go-kart part in about six months, but I spent a lot of time staring at the thing. As you know, a lot to consider. It’s hard to permanently mount the very first part, not knowing how it will affect the very last part. So a lot of mockup, a lot of trial and error.

By comparison, hanging the suspension, steering, brakes, dropping in the motor—easy. I spent time routing brake lines, nothing special, but it is a safety thing. I spent a lot of time routing wires, fuel lines, as I wanted everything hidden, safely mounted, and serviceable—not easy.

I mounted the coil packs off the motor so I would not have those wires exposed. When you look in the engine bay, you see nothing but the motor, clean. For me the wiring was the hardest part. It’s just not my thing. Plus I used a CAN Bus system, Infinity Box, for the chassis harness. I have no buttons in the car, no key, so it’s all touch screen.

Painting the thing was a nightmare, but of course I was going for perfection. I had to paint it two or three times. I had fisheye problems, and solvent pop problems.

So many times I would set a finish date, and blow way past it. I finally get done, and now the interior. Wouldn’t you know I had to add another 400 hours onto the build!

I cut apart the interior parts, reshaped them to fit the car. I made a docking station for a Sony Tab Pro. Sound comes out HDMI, then goes to an audio de embedder, from there to a digital amp. An all Audison system, great sound. And yes, I can hear it over the motor.

I made covers over the roll cage, very hard. The way I made them mount, and fit, and house the speakers, I amazed myself. Then I had to cover it with something, since leather would have been a fortune. I looked into paint, many options. I settled with hydro dipping.

First, though, I had to build a tub, and teach myself how to do it. I custom-tinted a base color so the carbon fiber film would look as close to real as possible. The center dash part was too big to dip in one session, so I had to dream up a way to do it in two dips and not look funny. That’s how the red strip on the dash was born, I get a lot of compliments on that. Then I made carpeted panels that I can remove to service the car.

As of now, the car is now 99 percent done (maybe). All I have left is to set up the traction control. All systems are good, it drives so nice. Very fast, and has lots of traction. At the moment, I have yet to let it eat. I am trying to get some enjoyment out of it before I break it.

There’s a very huge learning curve with this car, as it hits 90 mph in just a block, and the power-to-weight is insane. It is a race car in street trim. I love going to the shows, love the attention, love meeting the people the car attracts, it’s so worth the pain. Would I do it again? Man, I don’t know. This thing was hard.

My cost to build my GTM? I’m guessing less than $60k. It is the only car that I would be able to sell for more than what I have in it—that’s amazing!

Comments for: THE LONGEST DAY

comments powered by Disqus