Building an FFR Type 65 Coupe for vintage racing

By Karen Salvaggio

Photos by Steve Temple, Marshall Autry and courtesy of Karen Salvaggio

Say the name “Jim McKay” to anyone under the age of 40, and you’ll likely get a puzzled look in response. But for those of us who grew up in the 1960s, that name was well-known for that voice-over, “The thrill of victory, and the agony of defeat,” each week on ABC’s “Wide World of Sports” and educated us about the world of sporting competition.

Living back then in rural Pennsylvania, there were no racetracks in my little town. But right there in my living room, on a small black-and-white television, Jim and his colleagues quenched my thirst for automotive competition. I had no way of knowing then, but those mid-1960s Saturday afternoons, watching the spectacle of auto racing at Sebring, Daytona, Darlington, Le Mans, and other historic tracks, would set me on a lifelong journey into the racing world.

As a kid, I had followed Carroll Shelby’s pursuit of the FIA World Championship closely with my friends Jim McKay and Chris Economaki. We were a Ford family through and through, and while mom and dad worked out a new family-car deal at the local dealership, I would just sit and stare at the lone Cobra in the showroom or read the captions on the GT40 photos on the owner’s wall. Yep, I was gonna have one of those cars one day.

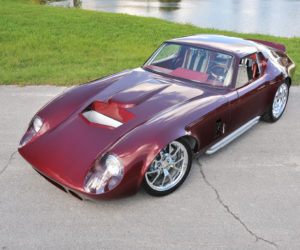

The iconic Cobras, with their massive engines and throaty roar were surely impressive, but it was the sleek design, the wicked power, and the endurance of the Cobra Daytona Coupes that captured my heart.

Fast-forward some 40 years, with a lifetime of personal and professional experience in the mirror, I finally took the opportunity to build my dream and pay tribute to one of the world’s greatest motorsports sagas. Only six original Daytona Coupes were ever built, and I knew that my retired schoolteacher’s income was not going to afford a “real” one for me anytime soon. If I was going to own and race a Coupe, it would have to be a replica, and with a little research, the Factory Five Racing Type 65 Coupe became my track weapon of choice.

The Factory Five Gen 3 R-model Coupe is the first full-race version of a replica Daytona Coupe to be offered by a component car manufacturer. The Gen 3 R-model Coupe utilizes a space-frame chassis design and represents a fundamental departure from the classic “ladder-type” car chassis designs employed in previous models. Using the inherent rigidity of a triangle, the square tubing in the space-frame design is rigid, lightweight, and more evenly distributes loads.

Available in both street and track trim, the R-model (race version) Coupe incorporates a full, SCCA/FIA-approved roll cage, including door bars, engine compartment, windshield, overhead cockpit, rear deck, and tail protection bars. This was the platform I wanted to base my new race car upon, and needless to say, I was thrilled to be selected as a beta builder for these cars. (See sidebar).

Fifty-plus years had passed since a truly new version (albeit replica) of a Daytona Coupe had been built, and the advancements in mechanical, structural, electrical and overall engineering processes in that time are astounding. Thinking the build through and calling back to the memories I hold of those iconic victories, I decided on a blend of tradition and modern technology, a car where “old-school meets new-school.”

The exterior would follow the design cues of the iconic Daytona Coupes from the past. The Guardsman Blue paint was formulated using the exact Ford paint codes from 1963, as were the Wimbledon White stripes and accompanying white paint on the recessed Kammback tail. The bonnet lifts forward from the engine firewall, as it did on the originals, and is held with latches on either side of the cowl. While it was truly tempting to add a plethora of aero details (to which even Peter Brock may have given a wink), I decided to keep it clean and remain true to the Coupe’s racing heritage. Under the hood, well, that’s a very different story.

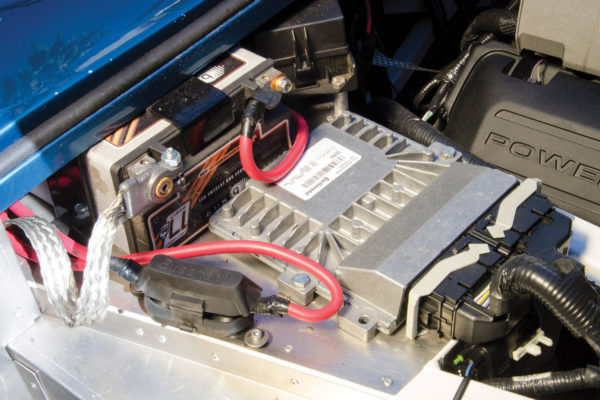

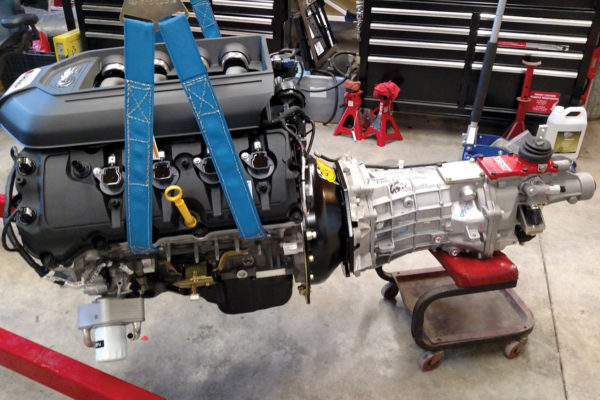

At the heart of the Gen 3 R-model is a 2017 Ford Coyote 5.0-liter crate engine, producing 435 hp and 400 lb-ft of torque, which easily powers the 2,622-pound car on the track. A TREMEC T-56 six-speed gearbox connects the Coyote power to a 2015 Mustang independent rear suspension with 3.73 gears and a Torsen differential. The stock Ford Coyote wiring, including a 5.0 Coyote control pack and Ford computer, complete the engine package.

With a 0-60 mph acceleration of 3.6 seconds and on-track speeds reaching in excess of 150 mph, the R-model Coupe requires huge stopping power. Six-piston Wilwood brake calipers on the front and four-piston Wilwood rears are more than up to the task, stopping the car from 70 to 0 mph in just 112 feet.

KONI coilover shocks effectively dampen the massive and rapidly changing load forces impacting the suspension, assuring constant tire contact with the surface of the track. A 50-50 chassis setup, based on the cross weight of the car, assures smooth and predictable handling in any racing condition.

The cockpit is Spartan in design, with one Kirkey race seat with Schroth six-point, FIA-approved seat belts, a fire extinguishing system, and a driver’s side window net. Vintage-looking Speedhut GPS gauges harken back to the Smiths’ gauges found in original Cobras, but with electrical signals providing reliable, and brilliantly backlit, engine performance readings for the driver.

So, what’s it like to drive this beauty on track? In a word: Thrilling! She made her track debut at the 2017 Spokane Festival of Speed and was wicked fast on a track filled with ground-pounding race cars in the Big Bore Group. The power-to-weight ratio is truly stunning, and with a chassis stiffness rating somewhere off the chart, the handling is simply sweet. She goes wherever you point her and gets there in a hurry. When it comes to a race car, it doesn’t get much better than that!

This car is a tribute to the amazing men and machines that left an indelible mark in American motorsports history. To the incredible team members and to the courageous drivers including the likes of Dan Gurney, Dave MacDonald, Bob Bondurant, Allen Grant, and many others — this little girl, and all of America, was watching. Thank you for giving us the thrill of victory!

A little help from my friends …

I was honored to get the call from Factory Five Racing owner Dave Smith letting me know I had been chosen as a beta builder for the new Gen 3 R-model Coupe. My first thought was, “Right on!” And two seconds later, my next thought was, “Yikes — be careful what you wish for!”

This project was far from my first build, so the actual wrenching was no worry. But when you are presented with an all-new chassis, no one else has one, and virtually every part on the car is either new, still in development, absent, or completely different from any of those builds in the past (with no drawings or manuals), it’s at these times that you’re thankful to have a few talented and very adventurous friends.

The chassis-to-roller stage of the build was accomplished at Ohio Cobra Club member and pro builder Dave Pohli’s shop in New Holland, Ohio. With the engine and driveline installed, the car was then moved to a good friend and pro builder Wayne Presley’s Very Cool Parts shop in Enterprise, Alabama, where the engine wiring, final plumbing, bodywork and paint were accomplished. Wayne and the amazingly talented builder Erik Treves brought the car to life.

With the freshly painted body on the chassis (doors hung; but no latches, windshield, or rear glass; and the hood taped in place), it was time to head to the Pacific Northwest for the final stage of the build, where I was thankful for the guidance of good friend (and legendary Factory Five builder and Bonneville speed record-holder) Farra Snook. Farra graciously opened his shop in Albany, Oregon, to me for the two weeks leading up to the Spokane Festival of Speed, where we worked virtually around the clock to finalize the seemingly million little details and prepare the car for its June track competition debut.

Although it was a beta build, with the help of these amazingly talented friends, the process was truly straightforward. The newer, wider design of the engine compartment and cockpit areas made for easy installation of the 2017 Coyote crate engine, as well as simplified all of the interior work. The only real challenges were fitting the door skins onto the frames and around the complex door bars so that they would still open and close normally (Thanks, Wayne!) and fabricating the tubing and mounting system for the 22-gallon fuel cell (Kudos to Dave.).

Comments for: Tribute to Victory

comments powered by Disqus