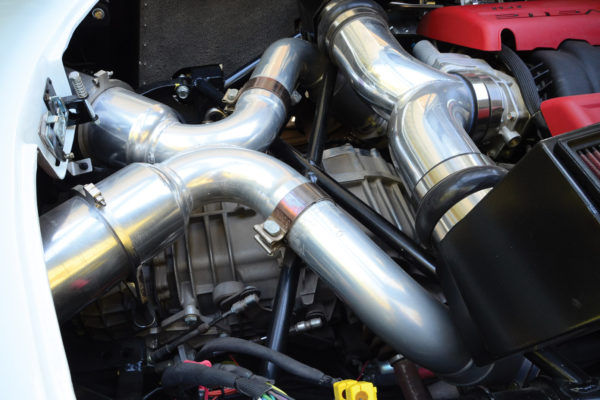

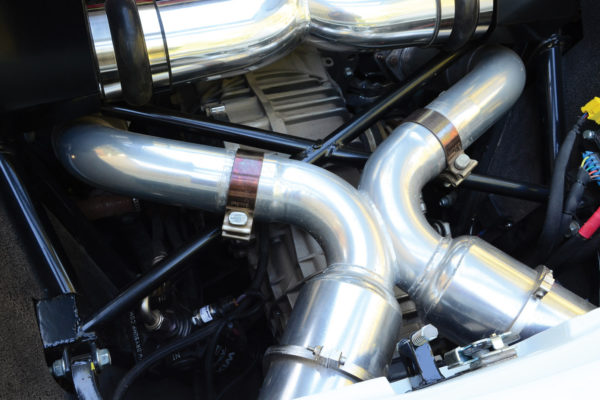

Factory Five GTM powered with an LS7 engine

As told by Wayne Mills

Photos by Steve Temple

I chose the Factory Five GTM after talking with my cousin in Texas who was building a Cobra at the time. I did some research and decided that I wanted to try my hand at building a GTM instead. Maybe just for the sheer challenge of it all, since I have never built a car anything close to this one. My previous car experience was changing out engines and transmissions as a teenager. So I spent a lot of time researching on the internet. Probably a little too much time, as I thought I needed to install every new “cool” thing I saw that would fit. As anyone who has ever sat in a Factory Five GTM can attest to, not much fits!

I chose to go with an LS7 engine, not really recognizing the trouble that I was getting myself into in mounting the oil tank. I probably spent a couple weeks, at least, finding a suitable frame area to reconstruct so the tank would fit. At one point I told my wife that she might have to give up her seat for the oil tank. She wisely suggested I push forward with re-engineering the frame.

Another challenge was hanging the throwout bearing fork into the inverted transaxle while mounting. We tried the old grease trick, and then tried hanging it with dental floss, but to no avail. Finally I talked my 14-year-old daughter into sticking her hand through the starter mount hole and holding the fork in place while my son and I slid the transaxle in place. (The family that builds cars together, stays together…)

On the other hand, most of the suspension installation and mechanical work went smoothly. As the build progresses, though, you start running out of room, which is pretty limited to begin with — so the challenges increase.

I chose Second Skin as a heat- and sound-deadening barrier. I built a spray table in my backyard and would sand, prime and spray 10 to 12 pieces of aluminum at a time. I literally thought I would never get all of the pieces sprayed. I am not sure how many pieces there were, but it seemed like hundreds. Tech tip: I took pictures of each piece prior to sanding so that I could identify them after the FFR part numbers were sanded off in the process.

Not being a glutton for punishment, there were two areas of the build that I knew from the beginning I wanted to sub out. One being the electrical, and the other the body and paint. After researching and trying to find someone to do the wiring for me, and while slowly installing more and more of it myself with the help of the guys at Infinity Box, I actually ended up doing the bulk of the wiring myself.

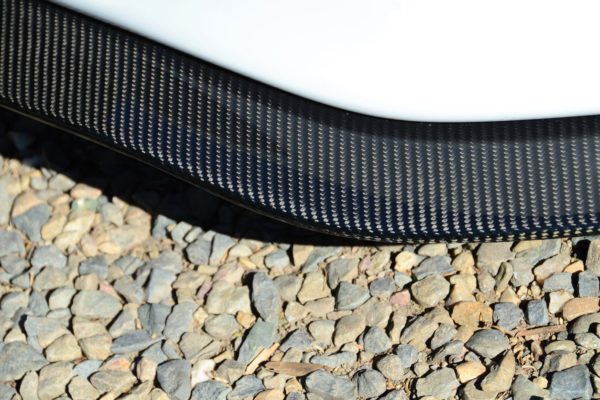

For body and paint, I chose to send the car out to V Raptor Speedworks. Shane Vacek, the owner, has built more GTMs than anyone on the planet, about 30-plus I believe. He had a number of custom touches as well that I wanted to incorporate into my build. He also does a great job at building window channels that seal up nicely. I ended being very happy with the fit and finish of my car.

While he had the car, I decided to go ahead and let him complete the interior work and install the lighting, escort system, race logic controllers, and LED lighting. I wanted to have a double DIN stereo receiver with a large enough screen for a good back-up camera. (Pretty much a necessity in such a low-slung car.) This step required the rebuilding of the dash panels to fit the Alpine Stereo.

We then had all of the upholstery sent off to Southern California to Elegance Auto Interiors. They did a great job reupholstering all panels with new leather, red stitching, diamond tuck on the seats and door panels and adding the GTM logo to both headrests and the dash panel.

Since having the car back from V Raptor I have not had much time to play with it, but have got it out of the garage a few times. We were able to make the FFR show in Huntington Beach this year. I trailered to that event because I had not yet gone through the registration process here in California.

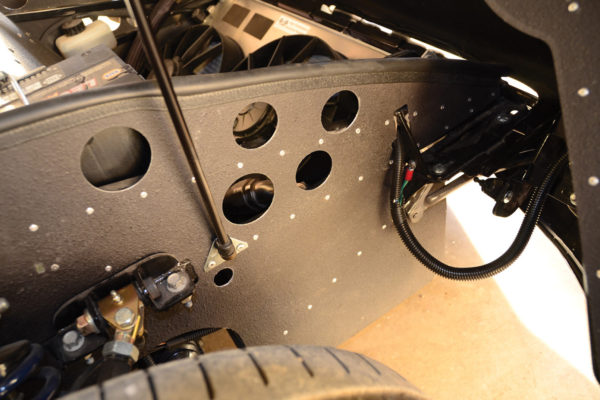

Another tech tip for other GTM builders: The one issue I have had is overheating, which is not uncommon for the GEN II cars. I have switched out the 50-50 mix of antifreeze with just water and water-wetter solution. I also changed out the stock thermostat from a 190- to a 165-degree unit, as well as cutting a few vent holes in the front wheel well aluminum to allow more airflow to escape from under the hood. My car has fender louvers so the heat has a place to dissipate. This combination seems to have fixed the heating issue.

All told, the project took a little more than three years to complete (if it’s ever really complete). But it was good enough to take home a trophy.

Comments for: Trophy Time

comments powered by Disqus