Amateur Hour: Ford Windsor Build Part 2

By Dean Larson

Tag along with us for the next couple months as a pair of total amateurs tackle the complete rebuild of a Ford 302 Windsor engine. Despite being obsessive gearheads and project car addicts, neither of us have ever rebuilt a car or truck engine by ourselves before. Our subject is a bare Ford 302 engine from around 1972 that we picked up from a shop for cheap. In the end, we hope to come up with a fun and reliable Windsor engine that any guy could build at home with a few helpful resources. Will we prove to be Windsor wizards, or will this thing kick out a rod immediately? There’s only one way to find out.

The more you know, the more you don’t know

We’re blessed to live in an era where information is a mere mouse click away, and you can learn most anything on the web. But there’s an unintended consequence for our purposes, and that’s that there are a million ways to do something, and everyone’s an expert. So when it comes to building our little Ford 302 Windsor engine, I’ve been spending my spare time trying to come up with a solid plan for how it should go together. I've been weighing alternatives and really trying to define the line we need to toe between our slim budget and doing things the right way. And it sure has been an education.

Right off the bat, I’ve discovered that we don’t really have an ideal starting point. To the uninitiated, our 302 Windsor block looks clean and ready for assembly, but that’s not really the case. The lousy invoice that accompanied our disassembled engine makes it seem like we have a torn-down 302 block that’s been cleaned and magnafluxed, but it turns out it’s bored .030” over as well. So now we’re talking brand new pistons, and a new displacement of 306 ci.

But that’s right about the time that I learned something about Ford 302s (and probably all stock engines for that matter) that most of you have probably known for decades. See I’m used to floating piston wrist pins, where the wrist pin can be more or less installed by hand, and is secured by a wire clip or Spirolock. Our stock 302 on the other hand, uses press-fit wrist pins, where the wrist pin is pressed into the piston and floats on the small-end rod bushing. Furthermore, the rods for our engine had been messed with some at the machine shop, meaning the small-end bushings had been heated and pressed out, and it was also nearly impossible to rematch each rod with its respective cap since they've been worked on. So at this point, our pistons are scrap and our rods are questionable, but the icing on the cake was the crank.

Our crank has some wear on the journals that you can catch a fingernail on, but it wasn’t that bad, and I read up on how to polish it with a shoelace and all that. Even so, we’d still need to work on it and replace the rest of our rotating assembly, and to what end? To have a Ford 306? It was about that time that I found a new course of action though, one that resolved the issues with our rotating assembly, and upped the power potential of our little Windsor significantly. Enter the bargain-priced 347 ci stroker kit.

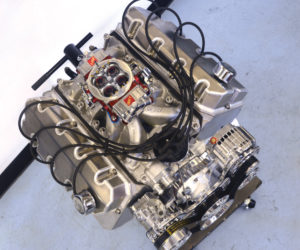

I was initially hesitant to pull the trigger on the stoker kit, as it sort of compromises our original concept of a super basic, dirt-cheap 302 rebuild that anyone can do at home, but hear me out on this one. The cheapest 347 ci stroker kit we found on Summit Racing was from Eagle Specialty Products, part number B16422LA030, and it costs $984.99. For that price, you’re getting .030” over hypereutectic aluminum pistons, rings, wrist pins, a cast steel crank, flywheel, external balancer and all main and rod bearings. Not only does this setup boost our displacement to 347 ci by increasing our stroke to 3.400 inches, but it also comes with the convenience of floating pistons, meaning we don’t have to pay for them to be assembled together, or risk breaking a piston by pressing them ourselves. Also, consider that we already needed to replace our pistons with .030” over units, and I'd really prefer to have a floating wrist pin assembly, which I assume means we're shopping for new rods as well. For this project, it just seemed logical to go with this brand new balanced kit that would yield a more exciting engine at the end of the day.

I’m not saying everyone should convert their 302 into a 347 stroker, as some folks aren’t keen on the 347’s rod ratio, and the fact that the 347’s wrist pin interferes with the oil control ring, but that’s a completely different topic. For us, it just made sense in terms of our abilities, the condition of our engine, our budget and the value of our power plant at the end of the day. For a decent condition engine with a standard bore, I probably wouldn't suggest spending the extra coin though, not unless you really wanted the extra cubes.

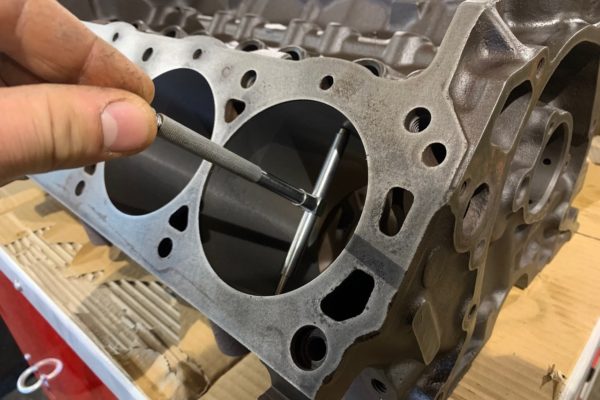

Moving forward with our setup, the stroker is going to require that we notch the bottom of our cylinder bores to clear the rod fasteners on our stroker crank. And to make the most of these new parts, we’ll also be spending more money on our cylinder heads and camshaft than we would have with a 306, with the added benefit of more horsepower of course.

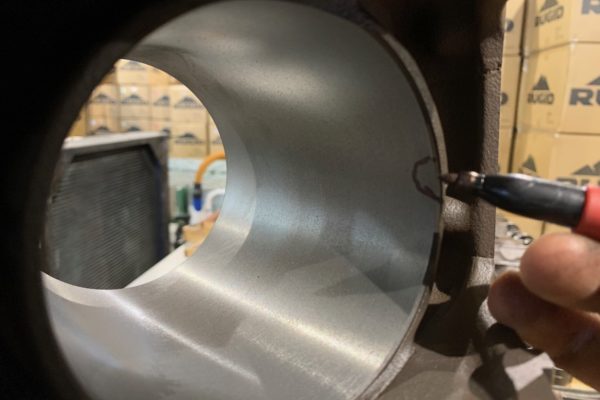

I know I’m getting a bit long winded here, but I also wanted to quickly talk about the current state of our block, and what it needs. Sure, we could just slam this engine together with new parts, a quick hone, new gaskets and bearings and it would probably be fine. But you’d light us up in the comments (for good reason), and we wouldn’t really be teaching you very much. As such, we have to accept the fact that our block is not ready for assembly and has to go back to the machine shop. The fact of the matter is that our cylinders have not been finish honed, a process where the machine shop hones the cylinder in accordance with how much piston-to-bore clearance your pistons require. Our block also really should be decked, have its cam bearings installed (as this process requires special tools) and we should have it line bored, since we have no idea who did what with the main caps.

Our next step is to verify exactly how far our cylinders have been bored to ensure that the machine shop can finish hone to 4.030”. From there, we can order our Summit stroker kit and mock up the crank, pistons and rods so we can mark exactly where our block needs to be clearanced. We’ll knock out any other block modifications that need to be done at this step before sending our 302 out to the machine shop to get it decked, line honed, finish bored and cleaned, all before the new cam bearings are installed. Doing things in this order ensures that our block and all its oil passages are clean and ready for assembly.

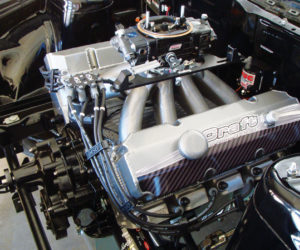

All this rigmarole leads me to question if our engine cheap DIY engine rebuild has gone off the script, but at the end of the day, I still think many guys would choose to do exactly what we did. I think we’ll have a really strong running 347 stroker at the end of this process making somewhere around 375-400 hp, and I think we’re giving it the best chance for a long life by doing our homework up front. Sure, we’re going to have to increase our budget, but we’re not talking about a dime-a-dozen 302 anymore — we’re talking about a 6,000 rpm capable 347 stroker!

Comments for: Amateur Hour: Ford Windsor Build Part 2

comments powered by Disqus