Amateur Hour: Ford Windsor Build Part 3

By Dean Larson

Tag along with us for the next couple months as a pair of total amateurs tackle the complete rebuild of a Ford 302 Windsor engine. Despite being obsessive gearheads and project car addicts, neither of us have ever rebuilt a car or truck engine by ourselves before. Our subject is a bare Ford 302 engine from around 1972 that we picked up from a shop for cheap. In the end, we hope to come up with a fun and reliable Windsor engine that any guy could build at home with a few helpful resources. Will we prove to be Windsor wizards, or will this thing kick out a rod immediately? There’s only one way to find out.

Shiny Parts and Slow Goings

When you imagine building a car, engine or most anything else, it’s easy to get caught up in romantic imagery of assembling nice clean parts, bolting on cylinder heads and tall swanky intake manifolds. But the reality of the process is a bit less romantic than that, and usually involves a lot more homework, measuring and parts cleaning than you imagined. That’s exactly where we’re at in the process currently, and there’s still some significant labor that needs to happen before we’re ready to start bolting anything together on this engine. But lucky for us, the U.P.S. man showed up this week with a box full of shiny goodies to keep our eyes on the prize.

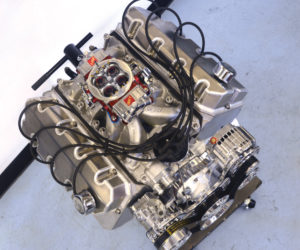

I broke the news last week that our 302 Windsor engine would be reborn as a 347 stroker due to the affordable price point and completeness of today’s SBF stroker kits. We had our eyes on an Eagle rotating assembly kit from Summit, which was a screaming deal at $985, but it would have been several weeks before we had the assembly, and our block can’t go to the machine shop until we have these parts. So in the interest of keeping this project moving forward, we pulled the trigger on a similar 347 stroker kit from Scat Enterprises. It includes a cast iron crankshaft, forged 4340 connecting rods with floating wrist pins, Keith Black KB hypereutectic pistons, Total Seal piston rings and King rod and main bearings. You can find this kit for around $1,018 on JEGS, under part number 942-1-94160.

Compared to our Eagle Specialty Products kit, the Scat kit is a little more expensive and doesn’t include a balancer or flexplate. This wasn’t a huge deal for us, because we’ll be installing a manual-trans flywheel, and balancers are cheap enough. We were also planning to have our rotating assembly balanced anyway based on a recommendation by our machine shop. The only other downside to the Scat kit is that it includes a cast iron crank, instead of the cast steel unit in the Eagle kit. But since we don’t plan on building the rest of the engine to support over 500 hp, the cast iron crank should be just fine. For all you keeping score though, the Scat kit does use a better steel alloy for the connecting rods, along with ARP bolts. The other big upside for us was that the Scat kit was available immediately, and JEGS had it on our doorstep over the weekend.

We’ll have a few hours to work on our engine this week, and our goal is to get any cutting, grinding, etc. we have to do done before it goes off to the machine shop. The easy part of this will be remedying the infamous oil galley plugs, which are notorious for leaking. For less than an hour of work, a few 1/4-18 NPT tapered pipe plugs and some thread sealer, you can be reasonably confident you won't have a leaker on your hands, or a loss of oil pressure. We’ll also need to grind clearance on the bottom of the cylinder bores for the stroker crank as identified in Part Two. Then the whole lot can go to the machine shop for decking, honing, cleaning, etc.

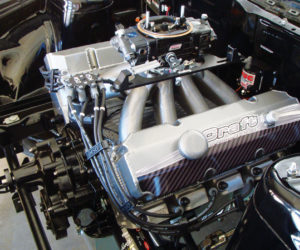

But in the meantime I have more homework to do, as I need to come up with a cylinder head and camshaft combination that makes sense for this engine. Since we don’t really have an intended application for the motor, I'll have to make a decision based on our budget and the spec sheets of more the affordable cylinder head offerings. I’d love to throw a set of AFR 195 cc heads on this engine, but the $2,200 price tag would kill us, and I’m going to have to come up with something decent for half that or less. I haven’t decided on a camshaft either, and with that in mind, I’m all ears for what combos you guys have experience with. If we use 64 cc heads, our two valve-relief pistons should make about 10:1.

I'm looking forward to hearing what you guys are using for cams and heads, but I also have a few sources to reach out to on my end. But with that said, it's time to start hacking up our block — wish us luck!

Comments for: Amateur Hour: Ford Windsor Build Part 3

comments powered by Disqus