Ford Windsor Build Part 4.1

By Dean Larson

Tag along with us for the next couple months as a pair of total amateurs tackle the complete rebuild of a Ford 302 Windsor engine. Despite being obsessive gearheads and project car addicts, neither of us have ever rebuilt a car or truck engine by ourselves before. Our subject is a bare Ford 302 engine from around 1972 that we picked up from a shop for cheap. In the end, we hope to come up with a fun and reliable Windsor engine that any guy could build at home with a few helpful resources. Will we prove to be Windsor wizards, or will this thing kick out a rod immediately? There’s only one way to find out.

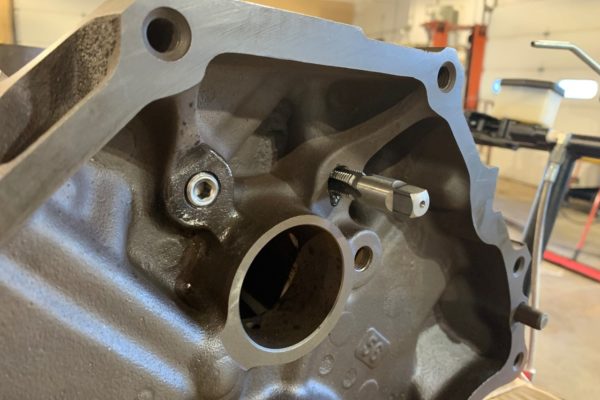

Yeah, yeah, I know; five whole installments and we haven’t even bolted a single shinny new part on our Ford 347 stroker engine yet. In fact, we haven’t even covered the nerve-wracking process of notching our cylinder bores yet, but I promise you, we’re getting to that this week. So at the risk of losing you on the little things, I wanted to give you guys one more update on the whole oil-galley-plug issue. Take this as more of a quick tip than anything, and I just want to quickly cover the rear oil galley plugs, along with the front plug behind the distributor today.

Starting with the topic of our rear oil galley plugs, I wanted to be sure that these three holes were ready to rock before I sent the block to the machine shop — as was the case with the three behind the timing cover. A rational person would have done them all at the same time, but as I’ve stated before, we’re amateurs.

Unlike the front oil galley plugs, all three of these holes were already tapped for thread in plugs, but the threads were a bit messy. So I ran our same tap through these holes that we used for the three on the front. On that subject, one reader suggested that the reason these holes were so difficult to tap, was that we were using a 1/4-18 NPT tap, when we likely should have been using a non-tapered 1/4-18 NPS (the S is for Straight, T is for Tapered), at least for the holes that were already tapped from the factory. Being an amateur, I’d say that there’s a solid chance he’s correct, but our block now has six 1/4-18 NPT (tapered) plugs in it anyway — live and learn right?

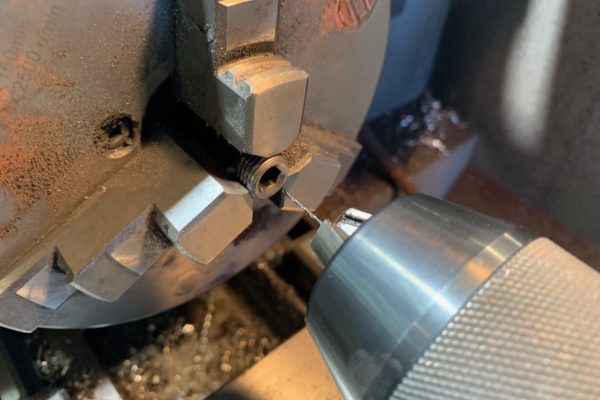

Moving on to the more valuable part of this update, I want to address a totally optional step you can do here to improve oiling to your distributor drive gear. We picked this up from Jim Woods of sbfbuilding.com, who indicates that adding a very small hole in the plug behind the distributor can greatly improve oiling to the drive gear on the camshaft. The hole is really small, .030-.040 inch, and we were lucky enough to have a .040 drill bit in stock and access to a lathe. So we simply chucked up the bit and the plug and ran it in very slowly while using cutting oil.

But of course not everyone has access to a lathe and a bit this small, and so one of Jim’s videos on sbfbuilding.com details a process where you can get a similar result at home. What you basically want to do is drill the smallest hole you can with what you have at home. I’d assume something in the neighborhood of 1/16 or smaller could be made to work. Then you simply take a ball peen hammer and medium size, blunt center punch, and repeatedly hit the hole. You’ll notice that this process will eventually decrease the size of the opening to something closer to what our .040 drill bit gave us.

If you’re building something that’s going to see regular abuse and high rpm, it pays to take this extra step now, instead of tearing through distributor drive gears down the road.

Comments for: Ford Windsor Build Part 4.1

comments powered by Disqus