Mesmerizing Metalshaping

By Dean Larson

Photo: Screenshot, Youtube user Gasolini

Metalshaping is dying art these days, and I think it’s because it’s a difficult concept for most of us to grasp. There’s so much more to it than pounding some sheetmetal over a form, and the real factors at play, shrinking and stretching, are much less intuitive than simply smashing something into a shape. But a complex skill like this one is truly made up dozens of smaller skills, a few of which are expertly displayed in this video by Gasolini, the latest installment in his YouTube series on constructing a Lancia-based etceterini from scratch.

In what has quickly become my favorite video series on YouTube, we’ve seen Gasolini start with a clean sheet, and design a unique Lancia-based etceterini, subsequently designing and fabricating a chassis and wooden body buck. Edited with occasional captions and a total lack of dialogue, the videos are an enchanting mix of educational and entertaining — must-see stuff for anyone building a car from scratch at home. I wondered then how his smart and simple building style would be applied to the forming of aluminum body panels (a mammoth task for the uninitiated) to shape his curvaceous Lancia. The answer is nothing short of mesmerizing.

In part four, we see the forming of the large sheetmetal sections of the body, largely accomplished with nothing more than a power shear, a bench and an English wheel. His annotated video clearly shows two different ways to set up the wheel for the purposes of adding curves and smoothing out a shaped panel. While these sections form the bulk of the mostly simple bodywork, there are a few compound curve areas, which he makes quick work of.

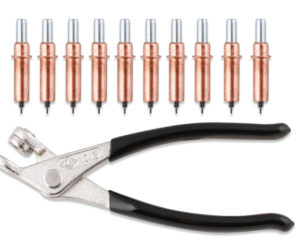

The more complex metalshaping was covered in part five, where Gasolini details the forming of three separate panels that make up a portion of the front fender. The shear and English wheel are used again, but it’s the shrinker/stretcher tool that really allows more radical shaping to take place. It’s particularly fascinating to see how this tool can quickly add radius to a curved panel. We’re also treated to a little over-the-knee bending, as well as the domed rubber mallet and sandbag for stretching as well.

By the end of part five, we’re really starting to see this unique car come together, and we’re looking forward to the next installment covering gas welding aluminum. Check out Gasolini’s earlier videos here if you haven’t already, and be sure to follow his YouTube channel.

Comments for: Mesmerizing Metalshaping

comments powered by Disqus