Rock West Racing Porsche 356

Story and photos by Steve Temple

Jim Goodridge has owned and worked on all sorts of cars, including a Cobra, Meyers Manx, and a couple Porsches. He had mixed reactions to the latter make, as his 993 was loads of fun, but his Cayenne proved to be less than satisfying. No more issues now, though, as his Speedster replica from Rock West Racing has been nothing but blue skies on a number of levels.

First, it has been a family affair, as he and his daughter, Anna, went through the build process together during her summer off from engineering college. She has the chops to lend a hand, having served as the captain of her school’s Baja team, competing in a custom off-road rig.

So the buildup was a nice way for father and daughter to spend some quality time together. Jim’s wife, Pat, got into the act as well, encouraging the project and steering him away from silver to a sky-blue paint job using an original Porsche color. (Nice choice, Pat!)

The body was painted beforehand at Rock West Racing, and arrived mounted on the chassis (but it’s also available as a component package). Rather than using a shortened VW pan, Rock West’s foundation consists of 2- by 3-inch steel box tubing (.125-inch wall thickness), plus round tubing to support the rear section of the body. Only a portion of a VW torsion tube is included, because it’s stamped with a factory VIN, in order to simplify registering the car as a VW Beetle.

The composite body is made of multiple layers of fiberglass cloth, matte and Coremat, all hand-laid and cured in the mold. Then the car’s frame is placed into the body mold, and they are bonded together with both adhesive and resin, and mechanically fastened as well for secure attachment.

The body-to-chassis adhesive is a two-part methacrylate that adheres to both composites and metals, but with enough flexibility to handle stresses from high heat and vibration. Once the body/frame assembly is removed from the mold, an additional bulkhead crossmember is added in the back to ensure the correct alignment and chassis stance.

Suspension components are then installed. At the front is a a VW beam axle with ball joints, reconditioned, adjusted and lowered for the RW Speedster application. Most customers opt for a later-model independent rear suspension, which is what Jim’s car has, fitted with new bushings and bearings. For crisp stopping performance, Empi disc brakes are fitted to all four corners, but Wilwood brakes are an option as well. Rock West adds a notch to the chassis that provides clearance around the disc brakes along with additional suspension travel.

Even though Jim claims his mechanical skill set is only fair to middling, he and Anna handled installing the wiring, steering column, gauges, brakes, shocks and battery. Simplifying both

the buildup and future color changes is a removable fiberglass

cover for the dash.

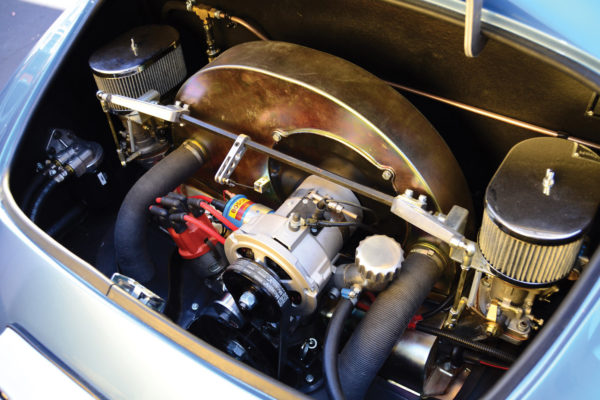

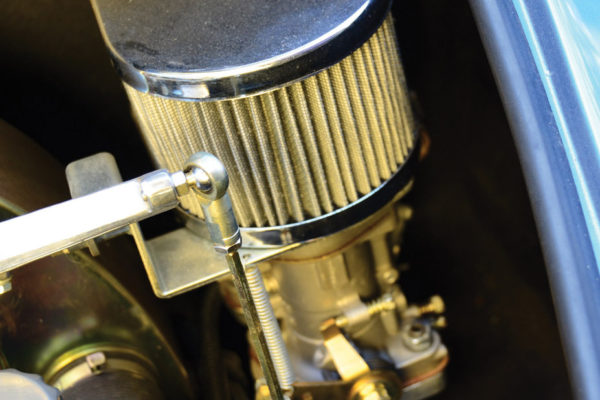

When Anna headed back to school in the Fall, the SCAT Type 1 engine still had to be installed, mated to a Rancho Performance transaxle with taller, “freeway flyer” gears. Displacing 2,180 cc, the VW mill delivers 125 horses, about triple that of a stock 1,600 cc lump. Given the car’s light weight overall, Jim feels that’s plenty of beans, and the handling is lively and fun. Just like Ella Fitzgerald once sang in Blue Skies, “Never saw things going so right!”

Comments for: Blue Skies

comments powered by Disqus