Aluminum roadster designed and built at home

As Told by Kris Heil

Photos by Steve Temple

When I was nearing retirement, I knew I was going to want a project. I was moving away from most of my friends and the cars I was helping them with, so I would be on my own.

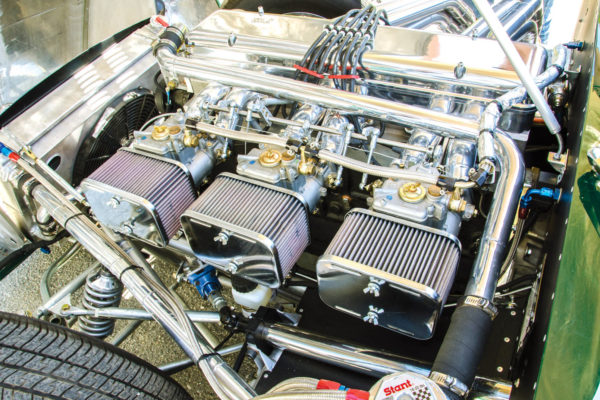

The project began with the engine. In 1999, I ran across a pretty rare cylinder head for a straight-six GMC. I did some research and found that the GMC sixes — in 270 cid form, and later as 302 cid — were a hugely popular race engine in the post-war period. They powered most wartime trucks and other vehicles, and were robust and plentiful. Local dirt-track racers and builders of Bonneville cars adopted them, ran them, and developed them to a high degree. They were very competitive with the V8s until the Chevy small block came out. There is a dedicated core of enthusiasts still racing the GMCs. The head that I found, a Fisher 12-port crossflow style, was last run at Bonneville. It was represented as being in great shape, fresh from a well-known shop.

I have always admired the sports racers of the late 1950s, and was partly inspired by the Aston Martins of that era. They were slinky and sexy and just looked cool. Most of them had cylinders in multiples of six; It became a natural choice to build a car in that style with an engine from that period.

Over a period of five years I accumulated some parts and made some concept sketches. I retired in 2006 and began work in earnest. Working around the Jimmy 6, a four-speed Muncie gearbox, and some C4 Corvette suspension uprights and diff, I drew my car. I created a set of working drawings for both the body and the space-frame chassis.

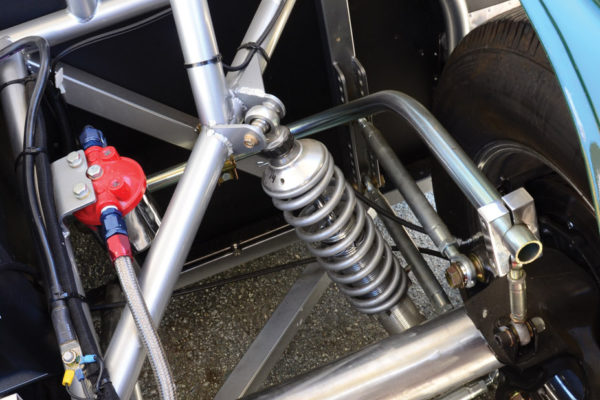

I then modeled the body in clay at 1/8th scale and the chassis in balsa wood to be sure that I had the necessary stiffness. I am not a CAD guy, so this was a pencil-and-paper project. I designed a suspension with a decent roll-center migration and camber curves.

Even though I had worked on road-race cars before and had a good idea what would work, building a street car is a whole different animal. I found that the California Highway Patrol had a brochure that listed all the vehicle requirements I had to meet and incorporated those in the design.

Mechanicals aside, the car was ultimately a design exercise. I was going to build the car that I could never afford. I knew I wanted to shape an aluminum body, but had never done that before. I took a few weekend classes and bought some DVDs (by Ron Covell). I built the MDF bucks, bought an English wheel and some aluminum sheet, and taught myself as I went along.

Over a period of 10 years I built the Daedalus. (Named after a figure in Greek mythology. The great perk of building your own design is getting to name it!)

When it was finally running I learned some important things from the school of hard knocks: The cylinder head around which the car was designed was junk. The rack-and-pinion steering ratio was too high. The Corvette brakes were useless without a brake booster. The spring rates were too stiff, and the first gear ratio was too high. The new Stewart Warner speedo didn’t work, and the cooling system needed a rework.

Other than those items, it was great! So, I started fixing the bad stuff. Thanks to the GMC loyalists, “The Inliners,” I was able to find someone’s abandoned engine project with a Wayne crossflow head (still super rare). After building new inlet manifolds for the Weber 45DCOEs, the engine was good.

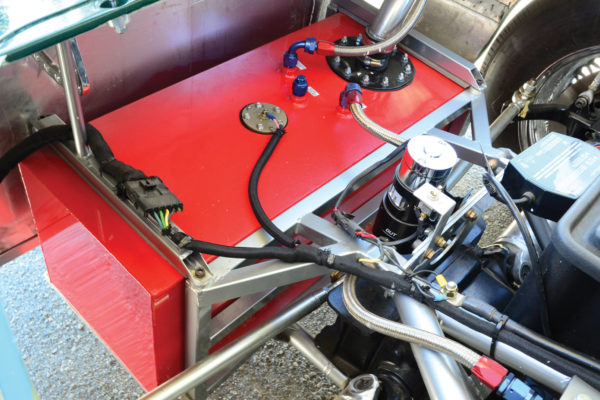

The transmission was borrowed, so I replaced it with a Super T-10 with a better first gear. Replacing springs on the coilovers was easy. I re-engineered the brakes for unassisted operation. I created a “big brake” system for a 16-inch wheel, something that doesn’t exist in the aftermarket. I spec’d custom floating rotors, hats, calipers and brackets. Once the engine was solid, I just upgraded the cooling system to a race car spec with a remote swirl tank.

I found that there wasn’t an alternate pinion ratio for the Woodward rack, so I used a steering reducer in the column. I just replaced the speedo with another new one. It was probably stupid, but the Stewart Warner gauges had the look I wanted.

The car ran the way I wanted, the weight distribution was what I was shooting for (50/50), and I got it licensed under SB100 rules in California. Then I took it all apart and sent the bits out for paint, powder coating and plating.

The painter (the good folks at Gary’s Rods and Restorations in Watsonville, California) did such a stellar job on the body that I had to up the ante on the interior. I went to Finish Line Interiors in Santa Clara. Byron told me all the things he wanted me to change on the interior fabrication to get the car to the next level. I took a deep breath and did what he suggested.

When I came to all the chrome, I went to Sher’s Custom Plating in Sacramento. They have a great reputation. I thought I was doing a terrific job until I took them the grille. I had about a month’s worth of work in it getting it just right. I put it up on the counter and Dave just looked at it. After about 10 seconds he observed, “God Himself couldn’t plate this grill,” and he began the litany of all things I had done wrong. I started over, and three months later I had a beautiful, plated grille.

I finished the car at the end of May 2016. It is a joy to drive, really quick, and looks exactly like my initial renderings. It is perfect to my eye. We have been invited to several shows and concours events, including a very prestigious one at Pebble Beach in August.

I have already started the next car, a little street-legal track day item with a delta-wing shape. The suspension design is done and I have a chassis mockup and a clay model. You might hear from me again soon.

Comments for: Flight of the Daedalus

comments powered by Disqus