Ford GT40 From Active Power

Text and Photos by Steve Temple

Following on the heels of our comparison between GT40 repros and Ford’s new GT concept in our previous issue, we came across an intriguing combo of old and new from Chris Ardern at Active Power. While we’ve hailed the Le Mans-winning design from the Sixties, clearly there’s been a lot of progress in automotive technology since then. Even though Ardern touts the appeal of reliving those glory days, his GT40 replica shown here isn’t mired in the past.

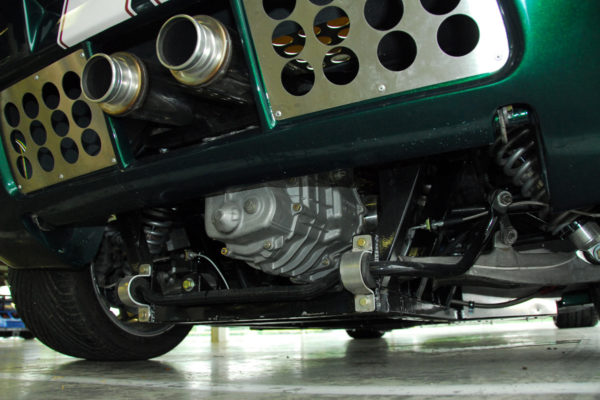

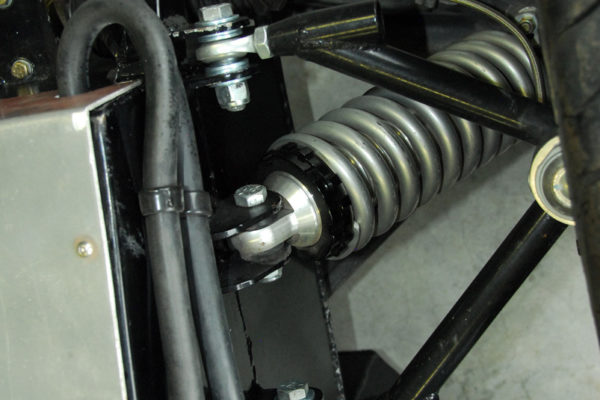

Instead, it employs parts from modern, readily available donors, such as the Corvette C5 and C6 alloy suspension, the result of countless hours and dollars worth of engineering development. In addition, Ardern admits that going to a Zero Scrub Radius technology for the tubular chassis required at least the 17-inch wheel, but the benefits far outweighed the limitation of wheel size. (Zero Scrub Radius simply means that the kingpin axis intersects the ground at or near the center of the tire patch.)

But using contemporary components is not simply a matter of bolting them on and heading down the road, since the weight and chassis configuration of a GT40 are dramatically different. As Ardern explains, “In the early phases of development, a friend and mentor John Truman, whom I worked with at Stoddard Porsche, was advising the project,” he relates, “He made the suggestion to get Jim Griffith, a local race engineer, to redesign the suspension geometry. He took the geometry of the 3200-pound, front-engine Corvette and eliminated much of the anti-squat and anti-dive to conform to the 2300-pound, mid-engine configuration of the Active Power GT.”

Fortunately, Ardern knew how to make the new design work, since he has substantial experience with building component cars, going back more than two decades on a variety of platforms, including Willys and the Urban Gorilla HMMWV replica. He also understands how to facilitate a project. Based his contacts with customers, “We learned what the builder wants from our years building Willys hot rods,” he notes. “The most desirable package is the complete fitted body mounted to a powder-coated chassis, with the doors fitted hinged and latched and the glass installed.”

Body fitment can be one of the most challenging aspects of a buildup, requiring specialized skills—and a lot of time, too. “We simply follow the same format as our Willys, offering our builder package with the brutally time-consuming fit-up work already done when you pick up your car. This is a big consideration for anyone shopping the component car market planning a new build.”

In addition to using newer Corvette suspension components fitted with QA1 coil-overs, plus a Porsche G50 transaxle, the Active Power GT also improves upon the original’s complex “bundle o’ snakes” headers, by using a simpler, more direct flow pattern.

“The header system is a set that came from the jigs we contracted Stainless Works to design,” Ardern explains. But with one limitation:. “These headers are limited to the 302-based block.” Now he’s getting calls for Ford’s 351 and Coyote engines and both require unique headers. “We are finding that it’s easier to custom-build each header system to order. That’s what we are doing.”

Ardern points out that the 351 has an 1 1/4-inch taller deck height than the 302, and with the 180-degreed configuration, the spacing on the headers changes so the 302 headers don’t fit the 351. Then there’s the added issue of firing order.

“The original GT40 used the 289 firing order,” he says. “But when working with the modern Windsor-based block, there is the HO firing order to consider. Many engine builders use the HO Cam with hydraulic roller lifters.”

The principle behind the design of Ardern’s 180-degree headers is to create an even scavenging effect from the collector. Each firing order requires specific timing as far as the exhaust collector configuration.

But wait there’s more—“If that doesn’t complicate things enough, the new Coyote has its own distinct firing order altogether. Ironically the Coyote has the same firing order as the Flathead,” he notes. But that’s doesn’t deter Ardern from accommodating custom requests, and he’s anticipating handling other engines in pipeline as well.

Just ask Karl Schuetz, the happy owner of the Active Power GT shown here. He recently took delivery of the car at the Carlisle Nats in May, after a two-year wait. He’s no newcomer to the replica scene, along with using an eclectic mix of parts, as he owns a Cobra with a 383 Chevy and five-speed Tremec trannie, plus a four-link Ford 9-inch.

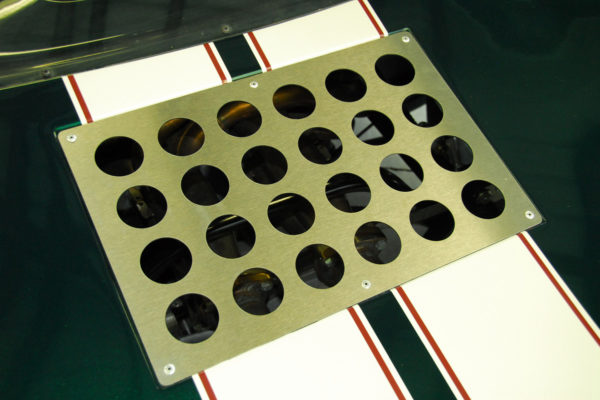

While he’s really happy with his Cobra, and personally handled several modifications on that car, he was smitten by the shape of the GT. Having a background as a residential contractor, he’s partial to green, so he had Ardern apply a late-model Jaguar hue. Other personal touches include recessed, push-button hood latches from Quik-Latch Products, for a sleeker look, along with four-inch-round, rubber-mounted 44LED truck taillights (which require a special flasher to activate). Ditto for the front directional lights.

While Schuetz acknowledges the help he received from Ardern and others, he pitched in to handle wiring and other details such as Lizard Skin sound deadening. After finally got behind the wheel, he was ecstatic about the performance: “It rides and drives like a charm. I couldn’t be happier!” But in addition to enabling him to relive the glory days of the GT, it offers a new reality, too.

Comments for: FUTURE TENSE

comments powered by Disqus