1938 BMW 328 replica

As told by Charles Walden

Photos by Steve Temple and Charles Walden

It’s strange how some project cars come about. I started my 1938 BMW 328 replica about nine years ago after reading the book The Spirit of Competition by the Simeone Foundation Automotive Museum and the film Easy Virtue only reinforced my passion for the build. Even though the movie starred Jessica Biel and Colin Firth, the BMW 328 was the real star in my eyes. This prewar roadster has been widely recognized as one of the most significant designs ever built and raced.

I started the project by purchasing an AUTOart 1/18th-scale die-cast model and used its proportions to produce a full-scale body. I used a 6-inch digital caliper from Harbor Freight to take precise measurements of width, length and size of every aspect of the model and then multiplied them by 18 to arrive at full scale. I figured that the beautiful model would at least keep me in the ballpark of the design elements, as I have never seen the real thing. Having previously built a replica 1967 Eleanor Mustang (yet another “movie star”), I felt confident to begin this project.

The donor car was a 1973 Triumph, which was a bit too short, so I stretched the wheelbase from 84 inches to 95 inches. Prior to removing the center section, I built a jig that attached to the rear and front portions of the Triumph frame at four points. The jig allowed us to keep the frame sections straight as we added length in the wheelbase.

A local fabrication shop formed new frame rails that were the exact measurement needed to extend the body. Prior to welding, a thicker, slightly undersized, square tubing was slid inside the frame rails at all four corners for added strength. Holes were drilled in the original frame so that the strengthening tube could be welded in place. Metal gussets were then added to overlap the old frame and new frame rails on both sides.

I placed 1-inch wheel spacers at all four corners, giving the approximate dimension of the original car and the ability to install 15-inch rims. The finished car would measure approximately 154 inches long and 61 inches wide. For rolling stock, 15-inch MG wheels provided the proper stance.

I started constructing the body by making cardboard templates that reflected the 328’s lines and then transferred them onto plywood. Once I had the shape in plywood, I wrapped the form in wire mesh and floated fiber Bondo over it, sculpting the form as I went. Thinking ahead, I made the fenders removable to ease the molding process. For some professional assistance, Chino’z Auto Body in Canoga Park, California, finished blocking the body buck and applied several coats of primer.

I took the finished body plug to Killer Instinct in Santa Paula, where owner Nick Mrozinski was able to make the fiberglass molds. The hardest part of the process was tossing the sculptured body plug in the dumpster after we were done, as I had spent so much time and energy to build it.

Nick made two bodies, and one had to remain in the mold to preserve its structural integrity. With the body completed, I was able to build a metal subframe, consisting of 2-inch tubing. Industrial Metal in Sun Valley made the curved portions of the subframe where needed, and their expertise was extremely helpful.

After mounting the reinforced subframe on the chassis and attaching the body, a few postproduction modifications were done to fine-tune my replica. The tail of the car had to be shortened, and the front was shaved a little in order to better reflect the shape of the original.

To that end, it was particularly challenging to fabricate the kidney-shaped front grilles, the two side grilles for the hood and a split windshield, but I was up for the task. Fortunately, Industrial Metal had sheet metal with various designs punched into it, including one that resembled the original article. I cut out the required shapes and welded them in place behind all four grilles. Astro Plating in Van Nuys handled the protective plating.

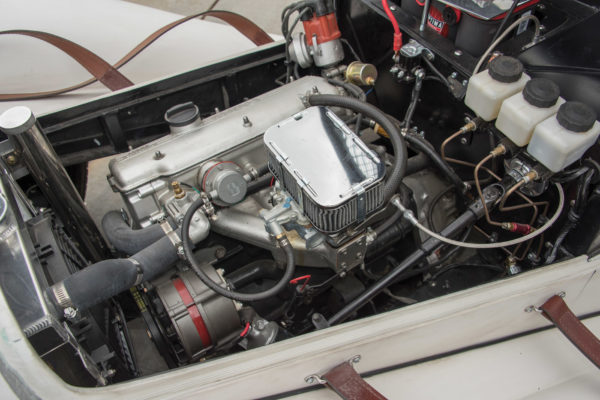

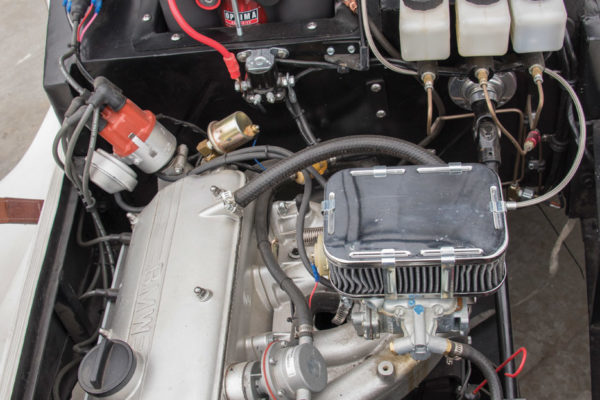

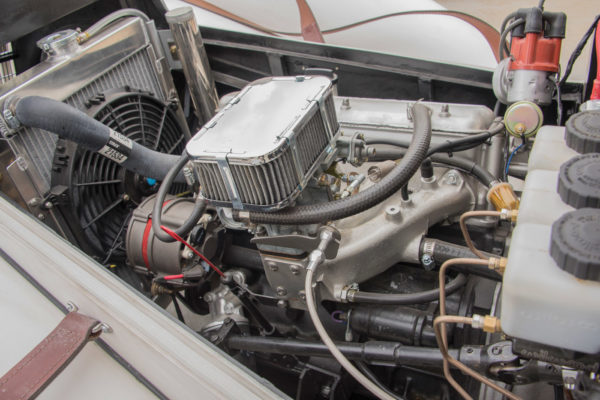

Wanting the car to have a BMW drivetrain, I purchased a used 1974 BMW 2002 M10 engine with a five-speed Getrag 245 transmission from a local BMW repair shop. The end of the output shaft on the transmission has a rubber flex-donut (instead of a universal joint), and obtaining proper alignment requires a two-part drive shaft. So I purchased a stock 1974 BMW drive shaft locally and had it altered to fit. This unit allowed me to install the entire drivetrain in the stretched Triumph chassis with little difficulty. I’m indebted to Ireland Engineering for its custom shifter and Canley Classic for a CV conversion kit, which simplified the whole process.

Ron Davis Radiators in Glendale, Arizona, built me a custom aluminum radiator — which was not cheap, but well worth the investment. The pedal assembly and master cylinders for the clutch and brakes came from Wilwood, and Limeworks Hot Rod Parts provided the steering column, banjo wheel and turn signals.

Once the car was in this state, I handed off the wiring and initial engine startup to Tri-C Engineering in Valencia, California. Rick Cresse and his expert team of mechanics completed the installation using American Autowire universal wiring kit, along with reproduction Porsche 356 headlights and reproduction Mercedes 170 taillights for turn signals.

Since standard issue sports car seats would not fit the somewhat cramped cockpit, I had to fabricate my own. Ricardo’s Auto Upholstery in Newhall covered them in luxurious Monticello red, and I’m thrilled with the final product. For modern convenience, I installed a Kenwood stereo under the dash with Bluetooth. I also fashioned grab bars for the passenger and center console.

After fitting on a new Weber downdraft carburetor and building a custom side-pipe exhaust, we were able to get the car running. Driving the BMW replica around the neighborhood is a trip, and I love seeing people react to a car that was originally designed in the 1930s. Through the project, I never tired of looking at the car’s graceful lines. In my opinion, designers of that era created the most beautiful automotive shapes, brought to life by fine artisans and craftsmen.

Obviously I took a number of liberties in recreating the BMW 328. This car was originally built in Germany from 1936 to 1940 on a tubular chassis with wood subframes covered in aluminum. Mine has a fiberglass body, and it rides on a metal subframe that hopefully will provide better protection. In a sea of modern vehicles that all look so similar, my car stands out from the crowd. Just like a movie star.

Comments for: Roundel Racer

comments powered by Disqus