Race Car Replicas MkI GT40

As told by Chuck Schmidt

Photos by Steve Temple

They say good things come in threes. Well, my son Ryan and I had a trio of reasons to undertake the costly and time-consuming project of building Race Car Replicas’ RCR40, inspired by a half-century-old Ford GT40.

First is the historical significance. Henry Ford and Enzo Ferrari had a spat in the early 1960s when Mr. Ferrari decided to renege on the deal to sell his company to Ford. So Henry Ford decided to break the winning streak Ferrari had enjoyed at Le Mans by building a race car to put Ferrari in its place. And he did. In 1966, three (there’s that number again) 7.0-liter MkII GT40s crossed the finish line together in one of the most iconic and dramatic Le Mans finishes ever. Next, a MkIV, also with a 7.0-liter engine, prevailed in 1967, but there is so much more to the story.

The French changed the rules for the 1968 race, limiting the engine displacement to 5.0 liters. The GT40 MkI was powered by a Ford 302, which met this requirement, and in 1968 a MkI (chassis No. P/1075) painted in Gulf livery of baby blue and orange swept across the finish line first. The exact same car repeated the feat in 1969 while competing against the Porsche 917, which was the most advanced race car of its time. This historical feat, combined with our preference for the small-block Ford, steered us toward the MkI.

Along with the historical motivation, we had some practical experience in car building inspiring us to tackle another build. Ryan and I had just completed an Everett-Morrison Motorcars Cobra replica, powered with a 427 side-oiler V8. We had such a great time building it that we just had to do another replica, so chalk the Cobra up as our second reason for building the RCR40.

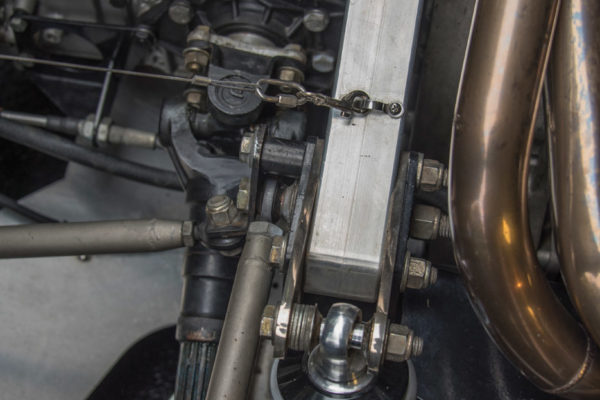

A bit of research led us to Race Car Replicas and its proprietor, Fran Hall. In 2006 we met Fran at his shop to check out his RCR40 kit. His enthusiasm was palpable, as he continually moved about, responding to questions instantly. We got a good look at all the major parts of the RCR40 kit while there, including the aluminum monocoque chassis, billet aluminum suspension components and fiberglass body molded from an original car. The quality of the build components had us sold on the project, our third and final reason needed to get underway, and we put down a deposit shortly after our visit.

Even so, building a car as complex as the RCR40 is not for the faint of heart. With no formal mechanical training and limited mechanical experience, I spent countless hours on the internet researching all aspects of the project and countless more hours documenting the progress. (Much of the documentation can be seen at our build blog, Chuck and Ryan’s RCR Build.)

Building the RCR40 leaves significant discretion to the builder. First and foremost is the drivetrain. Our objective was a period-correct small-block Ford, in keeping with an original MkI, which ruled out fuel injection and other out-of-place items.

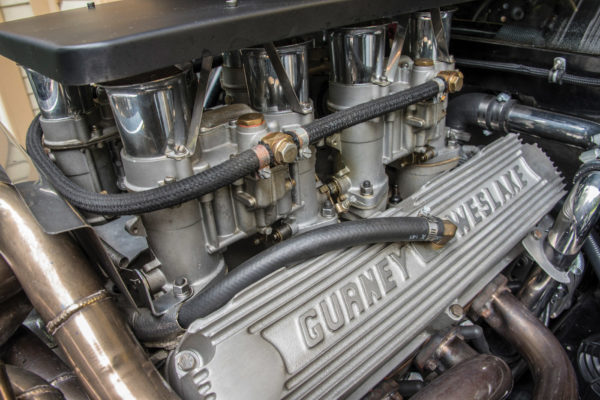

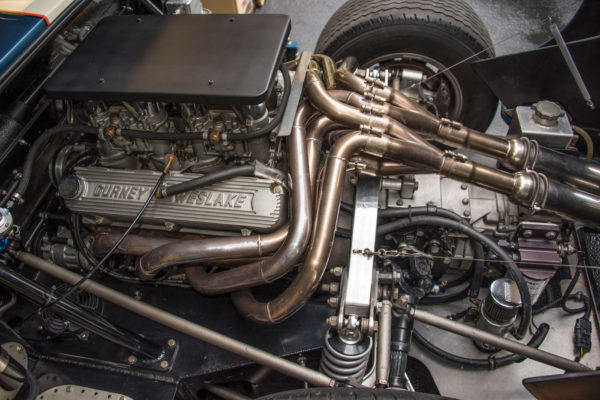

Actually, the drivetrain in our GT has been through three separate phases. The current, and final, setup is based on a new Ford Boss block stroked to 347 ci with Air Flow Research 185 cc heads. A GT40-type Aviaid oil pan, which is a bit shallower than a stock pan, is another detail. Of course the centerpiece of the engine is the induction, original-style Weber IDA carburetors, tuned by Jim Inglese. Completing the period-correct appearance of the engine are Gurney-Weslake cast-aluminum valve covers.

Another period-correct feature is the ZF five-speed transaxle. This unit is from the same family used on the originals in the 1960s. It may not be as smooth as the Porsche and other modern transaxles used by some companies on their reproductions, but the ratios are spot on for highway use and it has the correct look. As Fran is fond of saying, “The ZF has a more manly feel.”

Completing the initial construction of a reproduction is only half the battle, though. The other half is sorting it out, which requires a lot of time, attention to detail, research and thought. There’s also humility and the willingness to say “I goofed” and replace a bad part with the proper component. All told, a car that does not require sorting out is a car that has not been driven much.

This project has been underway for a dozen years and is now a solid performer, ready to drive at a turn of the key, a few squirts of fuel into the Webers and a push of the start button.

It hasn’t always been that easy though, and we had an interesting issue with the fuel system along the way. This RCR40 began its life with a pair of Holley fuel pumps, one on each side, for the two separate fuel tanks. Each was independently switched with proper filters and check valves. They worked well with a Holley four-barrel carburetor and the more modest engine that preceded our current power plant. They didn’t work so well with the Webers, though, which require a reduced fuel pressure of around 3 pounds.

It took a lot of head scratching and research to reach the conclusion that the Holley pumps, when pushing into such a low-pressure regulator, did not like lifting the fuel about 12 inches from the bottom of the tank, giving rise to a recurrent vapor lock issue. These pumps were supposed to be located below the level of the fuel pickup, so new pumps were in order.

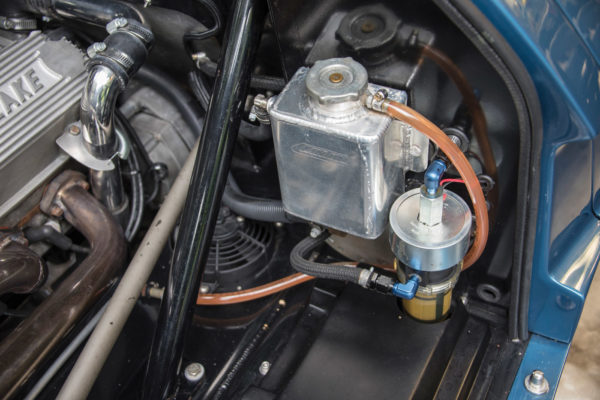

The solution was a pair of Facet pumps, designed to lift fuel far higher than the GT’s 40-inch-tall roof. They had the added bonus of including an internal check valve and filter, eliminating extra plumbing connections, which is a bonus when running fuel lines.

When a GT40 is racing around the track at well over 100 mph, a lot of air is flowing through the engine compartment, thanks to the side ducts. When driving through town on a hot summer day in stop-and-go traffic, the engine compartment can become very hot, and that is not healthy for the fiberglass body. So I looked for a way to enhance airflow.

After a lot of thought and research, I eventually settled on a pair of Derale fans that move 325 cfm each and fit perfectly over access holes on the sponsons on either side of the engine. The fans pull cool air from the back of the sponsons and blow it upward in the forward portion of the engine compartment. And then the cooler air is carried naturally toward the vents on the back of the clip. This setup does an excellent job of keeping the engine compartment cool.

When the ignition is turned off, power to the fans also goes off, creating the issue of a hot engine baking the rear of the car for several minutes. Now, an electronic relay maintains power to the fans for up to 10 minutes after shutdown, which further protects from heat sink.

Speedhut electronic gauges are a deviation from the original Smiths gauges, but the folks there worked with us to make gauge faces that capture the feel of the original gauges. And they are most certainly more reliable. The GPS speedometer is a real treat, eliminating a cumbersome mechanical hookup and it is dead-on precise. It picks up a satellite signal most everywhere, even in the garage. Lucas switches are used on the dash like the original, and surprisingly, they all work dependably.

Inspiration for the paint scheme came from the Shell promotional GT40, which was Guardsman Blue and Wimbledon White. These are the same colors that adorned many of the iconic Shelby 427 Cobras during that same time period.

With sticky Avon tires and QA1 adjustable shocks that are a bit stiffer than stock, the GT holds the road well. The sound emanating from the “bundle o’ snakes” exhaust as the Webers suck in gobs of air and fuel really gets your attention. With 500-plus horses in a 2,450-pound car, stomping on the loud pedal slams you back in your seat. The engine really comes alive above 3,000 rpm, as is typical with Weber IDAs, and the super-sticky Avon rubber really hooks up. It is a splendid driver, judged by the measure of a 1960s car.

As should now be apparent, there is actually a fourth reason for this 12-year endeavor — the thrill of driving it!

*Editor's note: Chuck Schmidt has yet another Race Car Replicas project in the works — a D-Type Jaguar. Follow his projects on Instagram @Contstant_speed37 and on Facebook at Constant Speed.

Comments for: Triple Threat

comments powered by Disqus