What is a Ford 351 Clevor engine?

By Dean Larson

Photos by Jeff Bruss

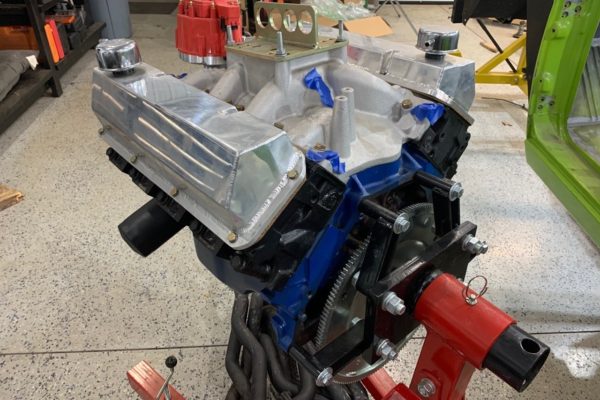

When it comes to the classic hot rodding engine platforms, bowtie guys have always had it easier than blue oval fans. Us Ford guys have a half dozen Windsor displacements, all the 385-series “big-blocks,” 10 or so FE engines and a few 335-series Cleveland “small-blocks” to keep straight. For example, there are at least three common 351 ci engine variants to know — the 351 Windsor, 351 Cleveland and 351 Modified. And when you think you have all those figured out, they throw the wild card at you, the 351 Clevor, essentially a Windsor block with 351 Cleveland cylinder heads. While building a Clevor engine isn’t exactly an A-B swap, you’ll be able to build gobs of horsepower for cheap with this setup, and get some serious props from old-school Ford guys at your local show. One of our friends recently picked up a 351 Clevor engine and had it sitting out in his shop, so what better time to get up to speed?

The origins of this ad hoc powerplant go all the way back to the late 1960s, when Ford was simultaneously using 385-series engines, 335-series Clevelands, Windsors and FEs. The lightweight, thin-wall casting Windsor block was the future for Ford’s medium-sized, road-going sedans, but the Windsor head just didn’t lend itself to high performance. Enter then the 1969 Boss 302 Mustang, equipped with a HiPo-spec 302 Windsor engine for Trans-Am homologation. The block was a high-nickel casting, and featured four-bolt main caps, a better crank, thread-in freeze plugs and an all-new cylinder head design. With borrowed geometry from the upcoming 351 Cleveland, the Boss 302 heads featured a canted valve design, which allowed for huge valves and ports. These free-breathing cylinder heads favored high-rpm use and provided 290 hp at 5,200 rpm and 290 lb-ft of torque at 4,300 rpm in stock form.

The Boss 302 engine was only available in 1969 and 1970 in the Boss 302 model, along with being optional in the Mercury Cougar Eliminator in 1970, meaning they’re quite sought after today. But back when aftermarket heads weren’t so common, savvy tuners found that you could build the same setup at home in your garage using a Windsor block and 351 Cleveland cylinder heads.

Way more common than its 351 Cleveland brother, Windsor blocks are lightweight, cheap and can be found just about anywhere. The aftermarket for Windsor parts is also massive, seeing as the engine was in use from 1961 to the early 2000s. Many also maintain that the Windsor block has a better oiling system than the Cleveland, especially when subjected to high-rpm use. Given the taller deck height of the 351 Windsor block, it's easiest to start with this displacement when building a Clevor engine, as it seems like the aftermarket intakes available today are not intended for the low-deck 289 or 302 engines.

As far as Cleveland heads go, you’re most likely to find 351C-2V or 351C-4V variants. The 2V heads are sourced from more sedate road-going cars and trucks with two-barrel intakes, and feature smaller ports and open-chambers with lower compression (2V heads can also be found on later 351M and 400M engines). These heads will make a bit less power, but are still a huge improvement over standard Windsor units, and perform great on the street where low-end torque is needed. You’ll start with less compression, but the Windsor’s strong aftermarket means you should have no trouble finding a piston that will yield 10:1 compression.

If it’s high-rpm performance that you’re after, it’s the 351C-4V four-barrel heads that you need. These heads feature larger valves and ports, and are available in both open and high-compression closed chamber configurations. When using the 4V heads, you'll want to tailor the rest of your setup for high-rpm use though, as these heads need air velocity to make peak torque.

So now you have a short block and some killer Cleveland heads, but there’s a bit more work necessary before you can bolt everything together. Both engines have the same cylinder head bolt pattern, but you need to first select the right piston for your application and make some modifications to the cooling system. Depending on which cylinder head you’re using, along with your target compression ratio, you’ll want to source some new flat-top or pop-up pistons that clear your valves.

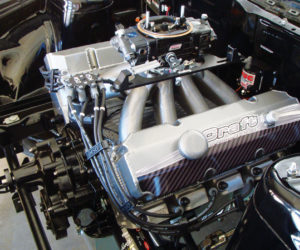

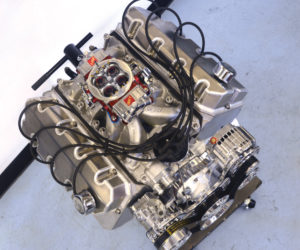

The next piece of the puzzle is an aftermarket intake manifold. In the past, supply of these manifolds was limited to a couple small manufacturers, but these days there are several great products available. The best options out there seem to be Edelbrock’s 7183, or Trick Flow’s TFS-51600111-51600113.

After you have these bases covered, your last big hurdle is the cooling system modifications. First, you’ll need to plug the two 3/4-inch coolant passages on the cylinder head deck surface, as they’ll overhang the Windsor block. Next, you need to drill three holes on each deck surface of the Windsor block to line up with the heads, which are easily located using a Boss-style head gasket. The last cooling modification depends on whether you’re using a wet or dry intake manifold (with or without a coolant passage).

If you’re using a dry intake like the Trick Flow unit, you’ll need to drill holes in the front face of each cylinder head and plumb a water crossover (Trick Flow makes this kit available for their Clevor offerings). A wet manifold, like the Edelbrock unit, instead requires holes to be drilled at the most forward part of the head, allowing coolant to flow through the manifold and thermostat. (Check out the video from Trick Flow Specialties below for more on these cooling system modifications.)

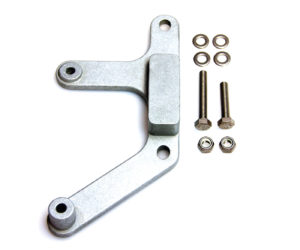

There is another product on the market from Price Motorsport Engineering that we’ve only recently found that simplifies the process even further. Price makes an adaptor kit that includes two adaptor plates, an intake valley pan, gaskets and hardware to swap Cleveland heads on a Windsor block without drilling any holes. The adaptor plates mate the Cleveland intake ports up to a standard Windsor intake manifold, while also retaining the wet manifold configuration and handling all coolant routing. The plates are only 3/8-inch thick, and Price indicates that a distributor kit is not required. Price makes several kits to accommodate different combinations of Cleveland heads, 351 Windsor blocks and Windsor or Cleveland intakes.

While drilling holes in your freshly-acquired engine parts may sound daunting, this swap has never been easier thanks to the purpose-built heads, intakes and gaskets available today. And with the huge surplus of Windsor parts on the market, you’ll be making a reliable 600 plus hp for relatively cheap. Not to mention entertaining all the graybeards at your local car show as well…

**This article has been edited to include offerings from Price Motorsports Engineering.**

Comments for: Anatomy of a 351 Clevor Engine

comments powered by Disqus