BluePrint Engines joins Factory Five Racing

By Steve Temple - Photos courtesy of Factory Five Racing

In the early days of build projects, it was not unusual to see components gathered from a variety of sources, including from a donor car and/or salvage yard. Like that old saying about a bride on her wedding day, the result was “something old, something new, something borrowed ...” and so on.

Factory Five Racing started out that way a couple decades ago, as its first Cobra replica required about 70 different items from a 5.0 Mustang, including the drivetrain. That was a great approach for the time, but the company has since come a long way. Today, most of their components are either made in-house or are new items from aftermarket firms. That includes a new supplier: BluePrint Engines.

To make things simpler for DIY car builders, this crate-engine company can drop-ship a virtually turnkey powerplant of the customer’s choice with a Factory Five replica. That means you don’t have to hassle with rebuilding a suspect engine from a used donor car or salvage yard. BluePrint provides a full warranty (30 months/50,000 miles) on its dyno-tested performance mills.

“The installation of a BluePrint crate-engine package is a high-water mark for Factory Five,” says Dave Smith, FFR’s founder and president. “It’s been a long time that we’ve been looking for a reliable supplier of high-performance warranty crate engines, and they’re also affordable. The crew of BluePrint are true professionals and their product is top notch, perfect for our customer needs and for our needs here at the factory.” As proof of Smith’s confidence, Factory Five demo cars have BluePrint engines in them.

Which brings us to this FFR Cobra replica. The previous engine looked good, but went south due to a cracked piston ring. While it could be rebuilt at a later time, it had an old-school setup, with outdated power delivery, so a modern and reliable plug-in replacement was needed.

Shared history

BluePrint was founded around the same time as FFR, each in a small garage. I visited FFR in Massachusetts back then, and did the first feature on this fledgling firm. It seemed clear to me that its single-donor concept would hit a nerve with car builders, and it certainly did, as FFR is now one of the biggest replica firms in the country. However, the company continues to expand on its initial approach, just as BluePrint has over the years.

BluePrint was established in central Nebraska, and what started out as a passion for performance turned into a hobby, then a job, and finally a career. Not unlike FFR’s grass-roots beginnings, the company began by building one engine at a time for friends and neighbors, and bit by bit the business and reputation grew among the dragstrip, circle-track and street-rod crowd.

Just as FFR has produced thousands of component vehicles to date, BluePrint has delivered more than 300,000 engines for both cars and trucks. Since FFR offers both Ford- and Chevy-powered component vehicles (Cobra or ’33 Ford), BluePrint’s full line features potential powerplants ranging from a Ford 306 to a stroked 408, and from a Chevy 350 to a big-block 454, along with Mopar engines.

Classic fit

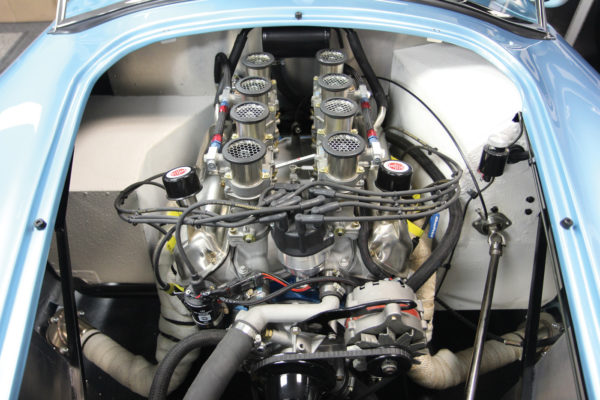

Fittingly, the BluePrint engine for FFR’s 289 USRRC Cobra replica is the same basic block used on the original Cobra, but align-honed and bored out .040” to 306 cubes, and fitted with modern upgrades such as new aluminum heads, hypereutectic pistons, a hydraulic roller cam, and either Holley carbs or EFI. On this particular application, FFR retained the Webers (four 48IDA units provided by Redline) from the previous engine, along with the accessory-drive system, since they were already in hand.

For FFR customers in general, BluePrint goes the extra mile and offers a drop-in turnkey motor. With this choice, all that’s required for installation is hooking up the battery, fuel and radiator hose. A TREMEC TKO 600 transmission can be included as well.

BluePrint breaks in each engine beforehand, and supplies a dyno sheet to verify the output. In the case of the 306, it delivers 390 horses, along with 370 ft-lbs of twist. Even with this prerun procedure, BluePrint recommends double-checking the ignition timing and using break-in oil, which should be changed after the first 500 miles or so. The engines come tagged with various instructions, such as pre-lube and startup procedures. The instructions advise re-torquing the manifold bolts after a heat cycle to ensure a proper seal.

For this specific application, FFR’s Tony Zullo, Dan Golub and Jim Schenck handled the engine install. They’re experienced wrenches, and shared a number of tech tips to make things go easier for fellow car builders, whether swapping out an engine or installing one for the first time in a project car. Check out the accompanying photos and captions for details. Some of these tips might be very familiar to experienced car builders, but some friendly reminders can be helpful.

Who knows, you might even glean some fresh approaches on how to handle your engine of desire.

Comments for: Engine of Desire

comments powered by Disqus