Spark Plug Wire Tech

By Dean Larson

Photos Courtesy of Koolmat

They seem simple on the outside; just some wires for conducting spark. Simple as running to the parts store, grabbing some performance wires and finished — beer time. While this will work just fine for many vehicles, you might want to take a second look if your application is any more complex than a 60-year-old pickup.

More than just a wire

The job of a spark plug wire is simple: conduct the amount of current necessary to bridge the spark plug gap and trigger adequate fuel burn. Maximizing fuel burn is the key to optimizing engine performance, but there’s more to it than just delivering the most charge.

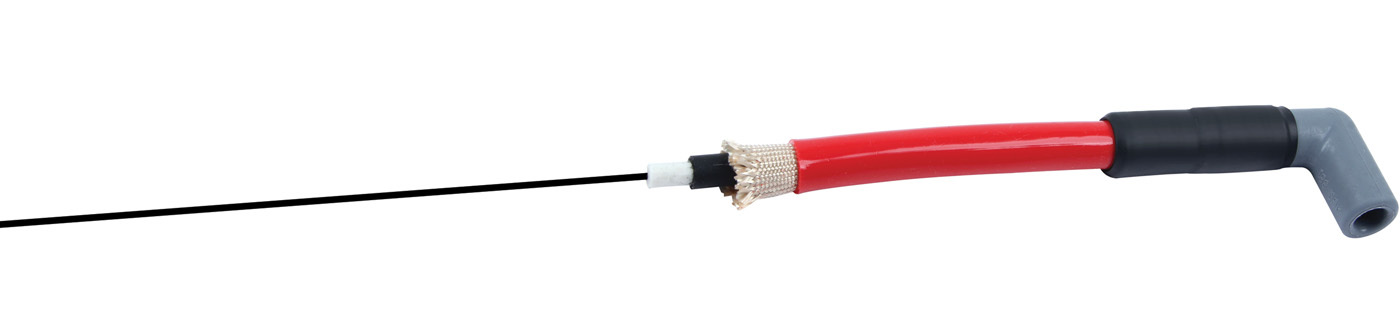

A spark plug wire can have up to seven different layers, cluing you in that there’s more going on than meets the eye. The outer layer of the wire is made from silicone and available in many different colors. All too often, a wire set is bought on appearance alone, but the silicone layer is designed to protect the wire from abrasion, heat, moisture and corrosion. A layer of braided fiberglass is next, and it provides strength to the wire and helps secure plug ends, preventing them from coming off when you pull on the wire instead of the terminal. The next layer is insulation, usually a silicone type, which is another layer of heat defense and prevents the escape of any electrical charge that has leaked through. Wrapping the braided core is a suppression layer that can vary by brand. It is the primary insulator, keeping electrical current from leaving the core and protecting it from any outside charges.

The problem

The original solution for conducting spark followed the same method we use to conduct most anything else, solid wire. This method was simple and provided low-resistance conducting, but caused some problems as electrical systems advanced. The current flow of each individual charge passing through the wire creates a magnetic field, which is switched on and off as each charge passes through. This results in an electromagnetic emission that can interfere with nearby electronic systems. The resulting radio frequency interference (RFI) was picked up by car antennas and heard through radios. In modern electrical systems, RFI can cause faulty sensor readings and interfere with solenoids and modules.

The OEM fix

The first solution for reducing RFI was the incorporation of a resistor on the wire end, reducing current flow and RFI. The logical next step was to turn the spark plug wire itself into a resistor by designing a completely new core.

Most OEM wires are the carbon-core type. Carbon-core wires replace the solid-wire core with a nylon or Kevlar core with embedded carbon fiber. Resistance is both the upside and downside of the carbon-core wire. It limits the current flow in the wire as a resistor, which keeps RFI down, but also limits the amount of current that reaches the spark plug. Carbon-core wires are a cost-effective solution for manufacturers, but their high resistance (over 10,000 ohms/ft. in some cases) is a limiting factor in performance applications, and carbon cores tend to be fragile and fail more often.

If you’ve upgraded your vehicle to make more power than stock, it’s recommended that you upgrade your plug wires. For a given cylinder displacement, all performance upgrades must increase cylinder pressure or rpm. With increasing cylinder pressures, you need increasing electrical current to bridge the spark plug gap and trigger complete combustion. This is the point when wire resistance is no longer your friend.

Solid core

While we’ve made solid-core wires sound like an antiquated solution, they’re still used today in many high-performance applications. The core in this type of wire is usually made from braided stainless steel or copper, which conducts current very well and has the lowest possible resistance numbers. This allows them to transfer the most electrical charge to the plug and make the most power. However, they do not suppress RFI and can’t be used with modern electronic systems. Generally, these types of wires are only used with high-performance engines using a magneto, or a points-and-condenser-type ignition.

Spiral core

The most common performance plug wire is the spiral-core type. Spiral-core wires start with a nonconductive core of nylon or Kevlar, which has an alloy wire tightly coiled around it. A coating is then applied as another layer of RFI suppression. This form has less resistance than the carbon-core wire, but produces less RFI than the solid-core wire. Spiral-core wires usually have resistance figures under 50 ohms/ft. and will help you get the most out of an upgraded engine with any sort of modern electronics.

So what should I buy?

Armed with this info and a basic knowledge of your vehicle’s electronic systems, it should be fairly easy to decide what plug wires are right for your project. The name of the game is obviously to have the least resistance possible, but the type of electronic systems in your vehicle is really the limiting factor. Good-condition OEM wires are perfectly adequate for (mostly) stock vehicles. These wires usually have around 3,000 ohms/ft. of resistance and up. As a bare minimum, you’ll want to stay above 500 ohm/ft. with a stock vehicle. If you’ve done some performance mods, it’s time to upgrade to a spiral-core wire to deal with increased cylinder pressures. Good spiral-core wires can have less than 50 ohms/ft. of resistance. A solid-core wire can measure virtually 0 ohms/ft. and is the best performer in theory, but the lack of RFI suppression limits its use to old-fashioned ignition systems.

Comments for: Fire in the Hole

comments powered by Disqus