Installing K&N Electronic Carburetor Injection System (ECI)

Story and Photos by Jim Youngs

While carburetors do a pretty good job of sucking in air and fuel to feed an engine, they can also be prone to a few typical issues. Poor cold starting, midrange hesitation, and losses during elevation and temperature changes are all characteristics you’ll see with the ultimate organized leak.

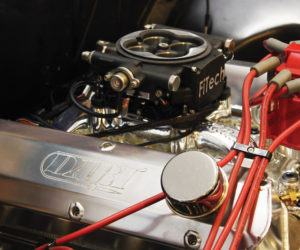

On the other hand, electronic fuel injection (or EFI) pretty much does away with those conditions, but it’s not without its drawbacks. From an aftermarket standpoint, building an engine with EFI or replacing a carburetor with EFI can be an expensive proposition. As an example, I opted for a throttle-body setup from FiTech Fuel Injection on two recent projects, and the systems cost me about $800 each, after rebates.

How about an effective and less-expensive alternative to EFI that would work with an existing carburetor? Well, look no further than K&N, a company most of us are familiar with for its performance air filters.

K&N has developed an innovative electronic carburetor injection system (or ECI), a self-tuning, bolt-on companion for a carburetor that addresses the carburetor’s common weaknesses. We had the opportunity to take a close-up look at the system and even install it on one of our project vehicles. As you’ll see here, the installation is straightforward and simple.

This setup is not exactly a new concept. Back in the 1990s, Mercury Marine touted an innovation for its biggest outboards that promised better cold starts. Long before the advent of EFI on those motors, it was a fuel enrichment system. Basically when starting a cold engine, the carburetors would get an extra blast of fuel for easier starting.

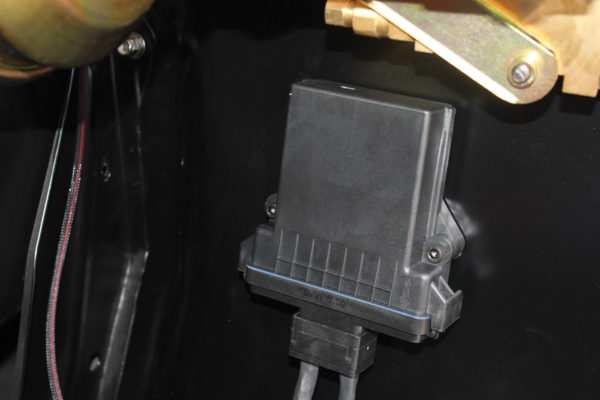

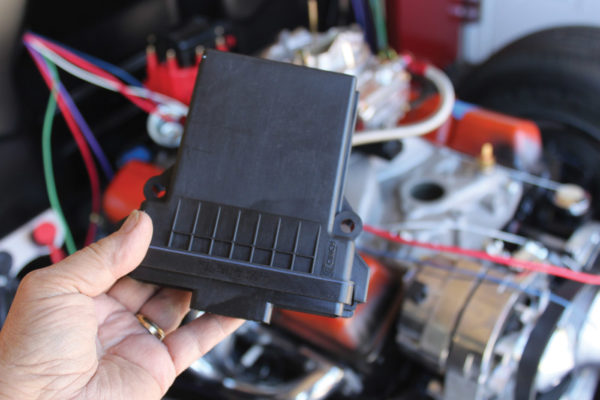

K&N’s ECI is a bit more sophisticated than those old Mercury systems, though. It includes an electronic control unit, or ECU, which constantly monitors input from the oxygen sensor, engine temp sensor and ignition to ensure an optimal air-to-fuel ratio. If it senses a lean condition, it injects more fuel to bring the air-fuel ratio back into spec. So, better cold starts, control of any stumbling or midrange hesitation, and compensation for elevation and temperature changes are all possible with this unit.

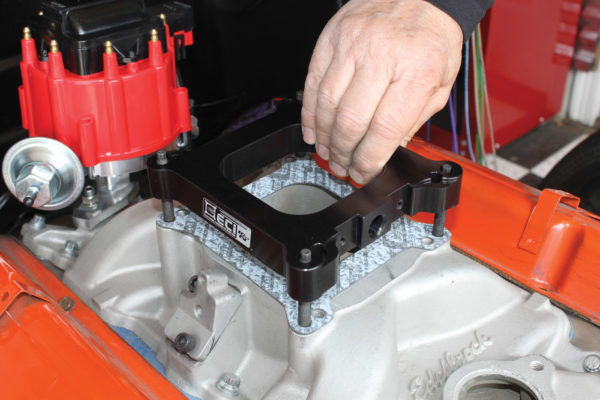

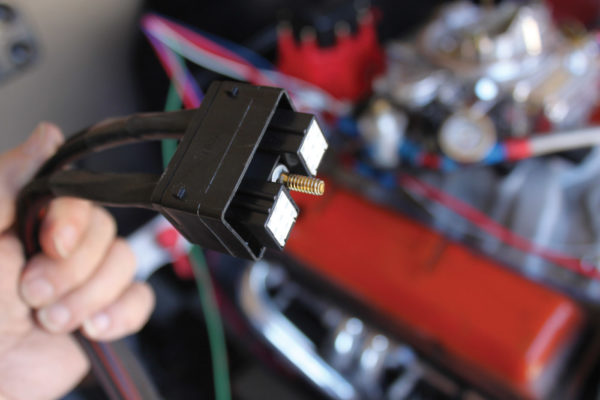

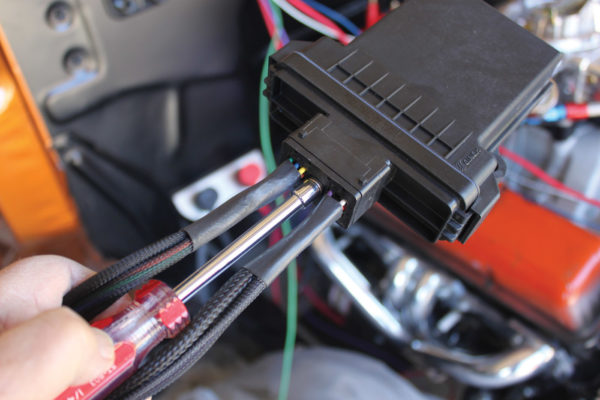

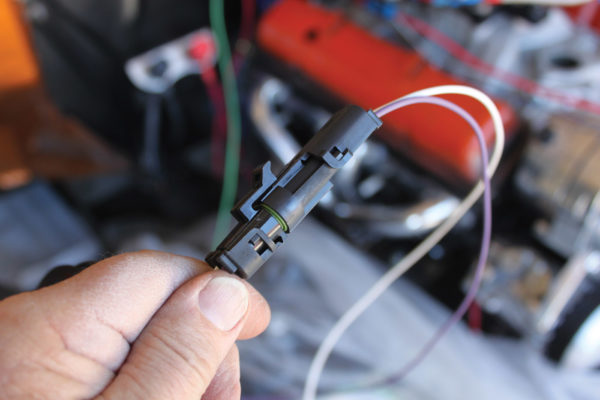

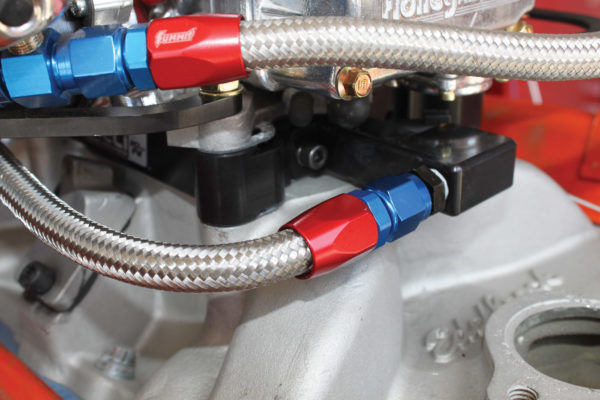

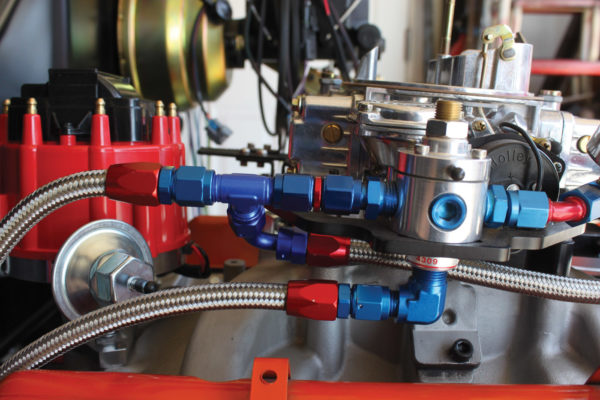

The K&N system consists of a carburetor spacer plate with integral fuel block, an injector (or in the case of a Dominator carb, two injectors), an ECU and a wide-band O2 sensor. Also included is a USB flash drive containing the necessary software for programming the ECU. The spacer plate is designed to hold the injector with an included fuel rail/clamp, and the ECU has proprietary wiring and plugs to tie everything together.

Users can opt to set the basic parameters initially, but they can also set more specific parameters such as injector pulse width, shot volume, progressive injector firing and minimum/maximum revolutions-per-minute range as needed.

K&N’s ECI kit comes fairly complete, but there are also a few optional items that are not included. Chances are you already have a temperature sensor, but if not, you’ll need one. You’ll also need some fuel line and a barbed T-fitting, along with perhaps a couple of barbed NPT adapters for the fuel line or AN fittings. It’s also likely that you might need an adapter to accommodate the tachometer wire lead. K&N recommends an MSD #8910.

The ECI installation we’re showing here is on a 1951 Ford F-1 pickup powered by a stock Chevy 350 ci small block. Hardly the type of vehicle we typically cover, but the project was in the wiring phase so there wasn’t a lot of hardware getting in the way of photos. And wire routing was much easier before everything was secured and hidden in a loom.

The Chevy V8 is fitted with a Holley 4160C carburetor sitting atop a 1-inch manifold spacer. We ordered K&N P/N 20-0001 ($499.99 for the complete kit) to get started. The kit offered a nice cost saving over EFI and should lead to an easy-starting and great-driving pickup.

Comments for: Induction Alternative

comments powered by Disqus