Fixing Cracks in Fiberglass

Story and Photos by Steve Temple

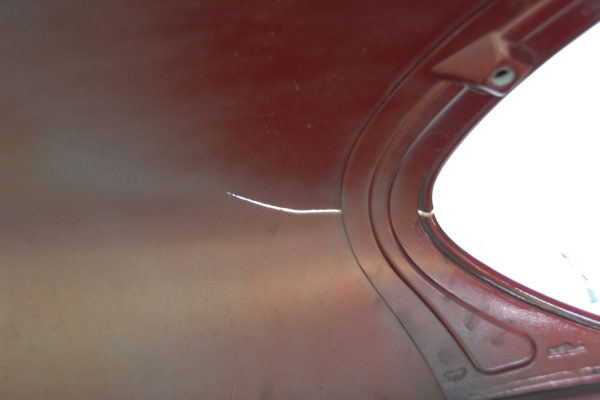

Considering that most replica bodies are made of a different material than those on production vehicles, repairing minor damage requires some special materials and techniques. We’ll focus on crazing (spiderwebbing) and cracking (usually from a slight impact). More severe body damage will likely require replacing large components by a pro, so we’ll limit our coverage to minor damage that can be repaired right in your own driveway.

For cracks or crazing, usually seen on older fiberglass bodies, there’s an innovative type of adhesive called Plastex that can repair a wide range of materials. In addition to repairing fiberglass, it can also be used to fabricate small components, and even works on metal (using a slightly different version of the repair kit).

The inventor of Plastex, Tim Lewis of G.T. Motorsports, has some pretty impressive credentials in chemical engineering.

In addition to being trained at the Northrop Institute of Technology, he’s worked on the adhesive tiles used on NASA’s space shuttle, and served as manager of Harrah’s car collection. So he knows his way around composite materials and how to take care of fine automobiles.

Using Plastex is a straightforward process, easier than working with resin and fiberglass. Unlike conventional resin and catalyst, for most repairs the mixing ratio doesn’t have to be in precise proportions, as long as the powder is thoroughly saturated. Depending on the type of damage, Plastex powder can be used with or without the cloth included in the kit, and it dries very quickly in a variety of weather conditions, so you can sand it and prep for paint in short order.

Comments for: Plastic Surgery

comments powered by Disqus