We Have Liftoff With the New Ecoboost Engine

Text and Photos by Pete Dove of Dove Racing, LLC

Taking advantage of advances in technology is a given when it comes to building a high-performance project car, especially when it can dramatically improving the powerto- weight ratio. So in the Spring of 2015, Dove Racing LLC began a project to determine the feasibility of installing a new type of crate engine in the Rocket 1: Ford Racing’s 2.0 Ecoboost. Manufactured by Road Track Race (now known as Exo Sports Cars) based in Nottingham, England, the Rocket has become a popular offering here in the States as well. Dove has imported and sold more than 30 of them to various customers throughout the States.

Previously, the powerplant used came from either a 2000 to ’04 Ford Focus 2.0 ZX3 or Focus SVT donors. The manual transmissions used were either the MTX-75 5 speed (ZX3 model) or Getrag MT- 285 6 speed (SVT model).

The new 2.0 Ecoboost that is installed in the 2013 (and up) Focus ST, uses a Getrag MM-6T 6-speed transmission instead, which has a completely different bolt pattern to the earlier style manual transmissions, along with taller gear ratios. As with the earlier engines, the Ecoboost engine and Getrag transmission package is horizontally mounted and therefore ideally suited for installation in the midengine position in the Rocket kits The reason for undertaking this project was firstly because the availability of suitable ZX3 and SVT Focus donors were becoming scarce. Secondly, the Ecoboost engines, through the use of direct injection and forced induction (turbo intercooled), produce substantially more horsepower and torque than the earlier engines (about 265 hp versus 175 hp).

Thirdly, the Ecoboost engines are aluminum (engine casting and head), and therefore lighter (even including the turbo) than the early engines. Another reason was that Ford Racing, after experiencing considerable testing setbacks during development, had finally developed a control package (part no M-6017- 20T) that includes a special PCM, fly-by-wire throttle pedal, plug-in engine wiring harness, and fuse and relay centers, that would enable the Ecoboost crate engine package to be used by hot rod and kit car enthusiasts. By using this new modern and lightweight powertrain, the Rocket becomes a serious and real competitor to the famed Ariel Atom for less than half the cost.

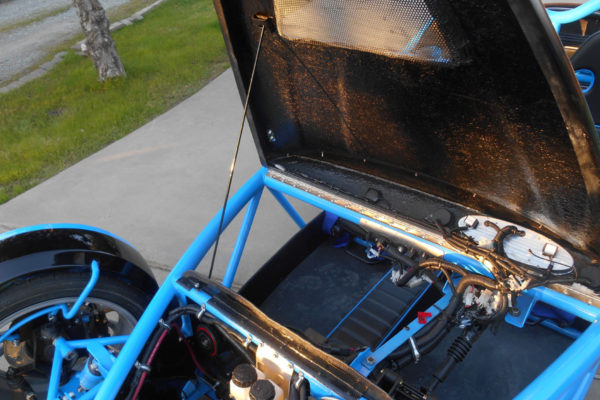

The first challenge was determining if the engine and transmission physically fitted the engine compartment of the Rocket. It was tight, but by using a leveling device hooked to the engine hoist and some careful maneuvering, it went in okay. The good news was that the existing structural engine and transmission mount bases on the frame were in the correct place with regards to the engine mounting brackets. For the driver’s side and rear mount, only a little grinding and hole repositioning sufficed.

However the passenger side base had to be modified by welding a suitably sized 1/4-inch plate to the existing mount and then drilling two new 3/8-inch holes to accept the bolts for the new Ecoboost engine mounting bracket. Also, a little grinding on the inside edge of the mounting bracket was necessary for this to clear the rear support of the rear roll bar. We added some extra structural members in the rear section of the frame to allow for the increased torque of the Ecoboost. Another bit of good news was that driveshaft geometry is almost identical to the Zetec or SVT engines.

The next task was to establish what driveshafts could be used. We started off with a new set of the driveshafts (right and left) from a 2014 Ford Focus ST. The passenger side uses an articulated shaft with a CV joint at the outer end. The inner part bolts to a bearing housing at the rear of the engine so it is necessary to use this part. We determined by measurement that both driveshafts have to be shortened (by about 3.25 inches on the passenger side and about 0.65 inches on the driver’s side). The next challenge was to interface the outer CV joints to the kit-supplied uprights. These are designed to accept the front bearings, hubs and 4-lug spindles from a 2004 Ford Focus SVT. The outer splines on the outer CV joints are a different configuration and the shaft has a larger diameter.

The best solution is to have new custom driveshafts made, which have 2004 SVT outer CV joints and then these will fit the uprights that are provided in the kit. A good driveshaft shop can do this and shorten the shafts to the required specification. Dove plans to offer these shafts as an option in the spring of 2016.

Next we tackled the shifter issue. Because the donor car has the transversely located powerplant mounted forward of the cockpit and with the Rocket this is located behind the cockpit, it is always a challenge to achieve smooth shifting with traditional positioning of the shifter handle for each gear. With previous Rocket builds we have used the SVT donor shifter, made some simple modifications to the shifter brackets at the Getrag MT-285 transmission and then used custom-made shifter cables to connect from the rear of the shifter, and then run the cables over the top of the engine to custom-made anchor brackets, and then connect to the transmission shifter levers.

In the original OEM condition, the shifter cables connect to the levers from below. However the SVT shifter does not shift nearly as smoothly as the newer ST shifter and Getrag MM-6T transmission. A further problem is that the shift brackets and lever mechanism at the rear of the MM-6T transmission. They are complicated and do not lend itself easily to modification to allow the cables to be connected from a different direction (i.e. from over the top of the engine) to maintain the traditional positioning of the shift lever for each gear.

We determined that best the solution was to use the ST shifter, run short, custom shift cables out of the front of the shifter to a custom lever arrangement that would reverse the direction of the shift movement. This involved two horizontal levers that fit onto vertical shafts though needle bearings, located about 24 inches in front of the shift lever. The short cables from the shifter (that deal with the side to side and fore and aft motions), each attach to one end of a lever through a Heim joint, and then a long cable is attached to the other end of the lever (again with a Heim joint) that runs back to the MM- 6T transmission to connect to the transmission shift mechanism similarly to the OEM set-up. The longer cables run back on each side of the shifter and handbrake lever.

The Ecoboost engine is fitted with an intercooler to be located between the turbo outlet and the intake manifold inlet. In the original ST OEM car, this is mounted in front of radiator. With the Rocket with the engine position behind the cockpit, it is not possible to mount the intercooler at the front of the car, since the hoses that connect it to the turbo outlet and manifold inlet are far too long, which would substantially decrease boost pressure. Thus it has to be mounted at the rear of the car.

The challenge therefore is to ensure that sufficient air enters the intercooler to make it efficient and effective. With the Ariel Atom, the intercooler is mounted in one of the sidemounted air scoops, which is located just in front of the rear fender. The problem with this approach is that it restricts the size of the intercooler.

The ST intercooler is about 48 inches long so the only place to locate it in the Rocket is behind the cockpit seats. This restricts air that can enter it because the backs of the seats block the air path. We decided to fabricate custom GRP air scoops that are located on both sides of the car in front of the rear fenders. And also to make a manifold that encases the intercooler. Four-inch diameter ducting connects the air scoops to the manifold. We also installed three, eight-inch diameter, high-capacity pusher fans that direct air to the intercooler at slow speeds, with air entering the manifold through the side scoops at high speed. The hot air that exits the intercooler escapes upwards from the manifold and in front of the rear engine cover.

The turbo and exhaust system on the Ecoboost engine exits from the rear of the engine. The catalytic converter is attached directly to the turbo outlet (exiting at a 90-degree angle and sloping downwards at about a 60-degree angle). With the engine mounted in the frame, the outlet from the converter just protrudes through the bottom of the frame at the rear. We fabricated a stainless steel muffler with the inlet in the center and the outlets at each end. We did not modify the catalytic converter at all and the resulting exhaust noise is perfect—not too loud, low and throaty. Future kit builders might want to remove the inner material from the catalytic converter to reduce restriction.

We have also added an oil cooler and remote oil filter mount (located in then right rear of the chassis). The cooler sits on top of the engine right behind the top air scoop.

We have installed a 2000 to 2004 Ford Focus steering column with ignition key and left switch stalk for canceling turn signals and high beams, along with a Sparco N310 steering wheel and NRG quick-release setup.

The instrument cluster is a Speedhut Legend series unit, and we added boost and engine oil temperature gauges to match. This cluster fits perfectly and includes a GPS-activated speedometer, tachometer, voltage meter, engine water temperature, oil pressure, and fuel level measurements. The fuel pump is from a Focus ST with the mounting set-up modified for installation in the kit-provided aluminum fuel tank (mounted behind the passenger seat). We also added a second aluminum fuel tank, mounted behind the driver’s seat, which when combined provide about 10 gallons of fuel capacity. The tanks are plumbed in common with a single filler cap located in a bracket that is welded to the front of the passengerside roll-bar. The fiberglass seats, offered as an option by ESC, were upholstered with padded black vinyl and trimmed with blue piping and stitching. The center tunnel also has been upholstered to match the seats. The seats are mounted on Sparco lowprofile seat runners which are fully adjustable. This arrangement allows a driver and passenger as tall as six-foot, four-inches to sit comfortably with adequate knee and leg room.

We selected Wilwood Powerlite four-piston front brake calipers (offered as an option on the Rocket 1 and 2 kits), 11-inch diameter drilled and slotted rotors (sourced from Brake Performance) and Wilwood high-performance pads. We also used the Wilwood clutch and brake-pedal set (which also comes with master cylinders). The rear brake calipers used are the standard SVT rear type, again with the 11-inch diameter drilled and slotted rotors.

The stock radiator found in all the Focus donors cannot be used since it is too wide to fit in the front of the Rocket. We sourced a Mishimoto three-core radiator (Part No MMRACIV- 92X) and used the high-speed fan from the donor radiator built into an aluminum shroud. The wheels selected were anthracite gray Anzio Vizio (17 x 7.5 inches) shod with Sumitomo HTZ3 205x50x15 high-performance tires.

In summary, the Rocket Ecoboost project has proved to be technically feasible. DRL plans to offer this package in Rocket Classic, Rocket 2, and Sonic 7 kits. All the modifications as discussed in this article can be performed to the kit frames before shipping. Dove Racing can also provide all the powertrain components.

In the case of the SVT option we can provide a used or rebuilt SVT engine and auxiliaries, and Getrag MT-285 transmission. In the case of the Ecoboost, Dove Racing can provide a new Ford Racing 2.0 Ecoboost engine and auxiliaries, engine control package, Getrag MM-6T transmission, intercooler, shifter, driveshafts and optional custom chassis wiring harness.

Getting back to our initial comment about increasing output while reducing poundage, how does the Ecoboost Rocket compare? With a power-toweight ratio of under five pounds per horsepower, compared with over seven pounds per horsepower for the SVT, the Ecoboostpowered Rocket is much quicker. In short noninstrumented test drives, we have established that 0-60 mph can be achieved in about four seconds (versus about 5.5 ticks for the SVT). Top speed is estimated to be about 160 mph (and about 142 for the SVT). While the top-speed numbers are rev limited in 6th gear, that’s still a massive boost in performance from the Ecoboost. We have liftoff!

Comments for: Rocket Science

comments powered by Disqus