Tips for outfitting an efficient workspace for your project car

Story and Photos by Jim Youngs

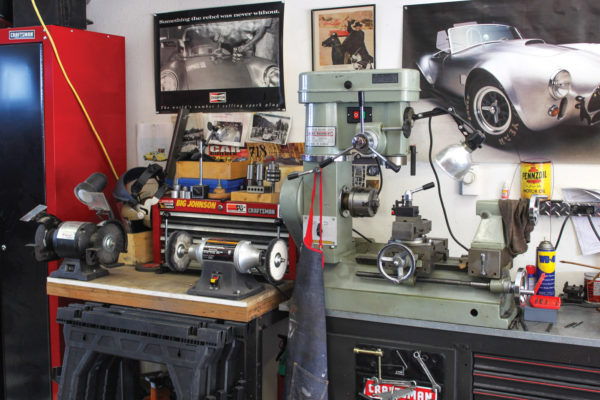

Regardless of the size of your shop, two things always ring true: One, there is never enough space, and two, good tools and handy gadgets take the “work” out of your workspace. These two axioms are the guiding force behind my “Taj Garage” (aka “Garage Mahal”).

So, what exactly is the Taj Garage? When my wife and I settled down about 16 years ago, we built our “forever” home. To me, the most significant aspect was my dream garage, an oversized six-car space that from the outside looks like a four-car suburban garage. Even so, I’ve had as many as eight cars completely enclosed in there, with room to move about and get at tools and parts. That’s because Taj Garage has 14-foot ceilings over half the space, lots of useful storage, and the most important tool of all, a four-post, drive-on, 7,500-pound service lift. And that’s just on “my” side.

My understanding spouse holds down “her” side of the Taj Garage with her daily driver and a hand-built ’57 Thunderbird replica built by Regal Roadsters. And there’s also a beer fridge, trash cans, lawn mower, bicycles, garden equipment, a tricycle, pink electric mini-Mercedes (for our granddaughters), and some miscellaneous household storage.

The Taj Garage also served for over 12 years as the mechanical lab and photo studio for Kit Car Builder magazine (the precursor publication of ReinCarNation), founded at this address. At any given time, it served as project central for many of the hands-on stories published in the pages of that magazine.

As the centerpiece of the garage, my Superior four-post lift has served me well over 15 years. Not only does it help me avoid crawling on the floor underneath project vehicles, it also makes many tasks like mounting wheels, installing heavy rear ends, wiring, and any number of others much more efficient. It even makes a pretty good paint spray booth with the addition of taped and strategically clamped plastic sheeting (check your local fire codes before copying me, though).

A couple of final thoughts on service lifts. Though it doesn’t happen very often, a four-post lift like mine has casters so that it can be moved — with some help. With my lift, I also purchased a stout jack tray that spans the ramps for raising a chassis or similar from the center. In several instances I wish I had bought two and may still do that some day.

The Importance of Wheels

Since I work by myself much of the time and have a touchy sciatic nerve, I find it necessary to have some typically uncommon tools nearby to help with the heavy lifting and space allocation. Things like an engine hoist, rolling carts, Roll-Master wheel dollies, transmission jacks and furniture dollies can serve as an extra set of hands in a pinch.

I’ve not only used my engine hoist to lift V8 engines in and out of cars, but also to boost heavy stuff into my pickup. My transmission jack came in handy one time to raise the rear of a chassis that had slipped off the lift. I bought a four-wheel Uni-Dolly to be able to roll a heavy car around, from which I’d removed the front suspension. My welders are on rolling carts, and I put engines on wheeled engine stands, and store heavy components like rear ends on cheap furniture dollies so that they can be moved quickly out of the way.

Floor Treatments

Shortly after our house was built and before moving anything into the soon-to-be Taj Garage, I mopped down the entire floor with muriatic acid and then rolled on two or three coats of gray epoxy paint. Aside from a sort of slippery finish, I liked that treatment for its easy cleanup. It also lasted about six years before beginning to peel a bit at the door thresholds. Professional floor finishes were prohibitively expensive at the time.

After a visit to a big shop with a floor covered with interlocking Race Deck plastic tiles with diamond plate texture, I decided to redo my side of the Taj Garage with a black-and-white checkerboard pattern of the same type. I found it to be initially cool, but I have a love-hate relationship with it.

I should have chosen a single, dark color since my shop projects can get messy. I’ve pretty much given up on trying to keep the floor spotless, mostly because I haven’t found an easy way to keep it clean. Also, the tiles are not very forgiving when welding slag escapes the confines of a welding blanket, but that’s probably the case with most floors of this type.

A Few Special Tools

Anyone who has read my ramblings over the past 40 years in motorsports magazines will know that I’m a tool junkie and regularly preach the gospel of having the right tool for the job at hand. I’m also a big proponent of jumping in to learn a new task like welding or painting for example, especially if those tasks require new tools.

Early on, I purchased a small 115-volt, wire-feed MIG welder so I could learn how to do that intimidating task. My welds weren’t pretty (some would say booger welds), but I managed to get pieces of steel to stick together. What I learned more than anything else with that rather weak machine was that more power — 220 volts — would make me a better welder. As such, an Eastwood MIG 175 has taken up residence and is used regularly. Subsequently, an Eastwood TIG 200 has also been added.

I’m also quite fond of my Eastwood Versa-Cut Plasma Cutter that cuts through steel up to 3/8-inch thick like a hot knife through butter. It makes fabricating brackets and such very easy and precise.

Additional Tool Considerations

Clamps are items that are easy to overlook in the shop, and I’ve discovered that you cannot have too many. I have a drawer full of all sorts of clamping devices and still find myself wanting on some projects. Particularly useful are spring clamps of varying sizes, C-clamps, welding clamps and even some stout magnets are very useful for holding parts together for welding.

I keep a collection of small pneumatic die grinders with various cutoff wheels, burrs, and sanding discs handy. Harbor Freight seems to always have them on sale for about $10 to $14.

Equally handy for the toolbox is a good collection of hammers. I particularly like my 4-pound dead-blow hammer, ball-peens, brass head hammer and small sledge. I also have a couple of hammers that have interchangeable hard and soft heads for varying levels of persuasion.

An under-hoist stand is very useful, and I’ve used mine for numerous holding situations and even some lifting processes under the lift. I’ve even used it as a light stand to which I clamp a pair of halogen work lights. And I’ve found several situations where more than one would be even more useful.

I suppose I could write an entire book on useful tools and shop niceties; it’s probably a lifetime pursuit to have a shop loaded with every imaginable tool. But then again, there probably won’t be enough space.

Comments for: Tool Time

comments powered by Disqus