FII Roadsters all-aluminum Shelby

Bob Wingard of FII Roadsters says he now has the sole rights to manufacture the Shelby Series 2, parts for Series 1 and an agreement to add the FII 427 Roasters to the registry as a Shelby Tribute car with a Shelby Manufacture Certification of Origin (“MCO”).

“I’m going to make the Shelby Series 2 a 427-powered small block or FE with a 5-speed transmission,” he says. “The body options will be carbon fiber or aluminum, but the one for myself will be titanium—that will be a first!”

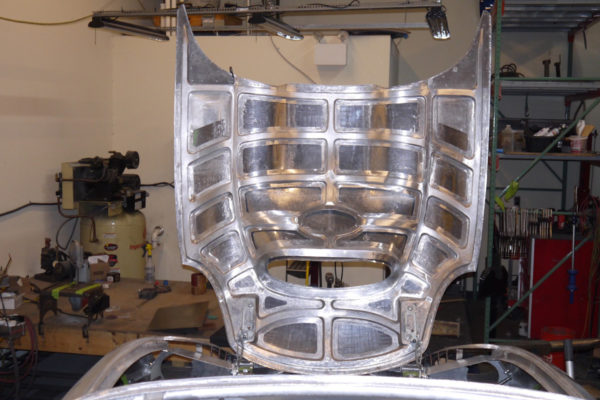

The plan for the platforms is to build original, serialized, all-aluminum Shelby Series 1 production frames, with front and rear crumple zones and side-impact protection, just like the original cars, along with FII’s performance drivetrain, brakes and suppression upgrades. And if a customer installs a Shelby engine, they will have matching numbers.

Drawing on his skills as a NASA engineer, Wingard says the composite body uses true aerospace-grade, 4-ply carbon fiber that’s vacuum formed and cured at an elevated temperature, as done in the aerospace industry and Formula One cars, making it much stronger and lighter than the wet layup more commonly used.

As for the metal bodies, “They raise the bar but not the weight, separating them from everyone else,” he explains. “Titanium will be the first U.S. supercar with a titanium skin, as as thin as the originals but stronger than steel, because I like to be different.”

Wingard expects the first aluminum body to be completed this Spring, and there will be a limited number available due to what it takes to produce them by hand. Summing up this new project, “I look at this as continuing the dream or vision and staying true to the history and legacy.”

Comments for: New Bodies for Shelbys

comments powered by Disqus