Creating a shiny metallic-looking part with Barracuda Glass

Story and Photos by Dan Burrill

Most project cars don’t come with every single part you need to complete the vehicle. Sometimes you have to make them yourself, especially if you want a custom treatment. For instance, when we started restoring our old fiberglass hot rod roadster, the body was nothing but a shell. There was just a big empty space where the firewall and dashboard once resided. To fill this area, we decided to create a brand-new mold and make a new part from a special fiberglass product on the market.

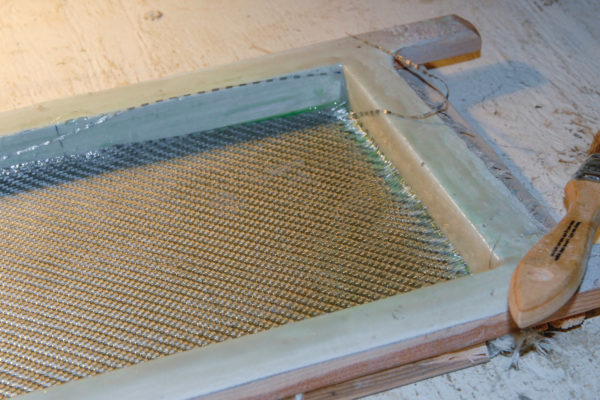

Since it’s a vintage roadster, the dashboard would be fairly simple in order to be period correct. After all, back in the day they were basic cars with lots of flat planes. So all this project needed was a rectangular-shaped panel without any curves. It would measure about 38 inches wide, 6 inches tall and about an inch deep. The finished dash would fit into a metal frame in the cockpit, so the top and sides would be left square.

For an item like this one, it’s a good idea to first figure out what is going to be mounted in the dashboard panel and where each piece is going to be placed. The placement of a stereo, engine instruments, toggle switches, keyways, indicator lights and so on will determine the actual size of the dash. The width is somewhat determined by the width of the car, but there is some leeway on the depth and shape.

A narrow, angle iron framework provides much-needed support for the fiberglass dash panel. It also allows for complete access to the back of the instrument panel by simply removing a few screws. If you’ve ever had to crawl upside down into a sports car to get to the dash wiring, then you understand how nice it is to have a removable instrument panel.

To achieve a nostalgic look, we used a Volvo Penta instrument panel out of an old boat. This style was considered hot stuff back in the 1960s. Looking for something different, custom hot rod builders would often use instrument gauge clusters, and entire instrument panels out of boats and airplanes. For ease of installation, the instrument panel was mounted directly on top of the fiberglass dash panel (rather than recessed).

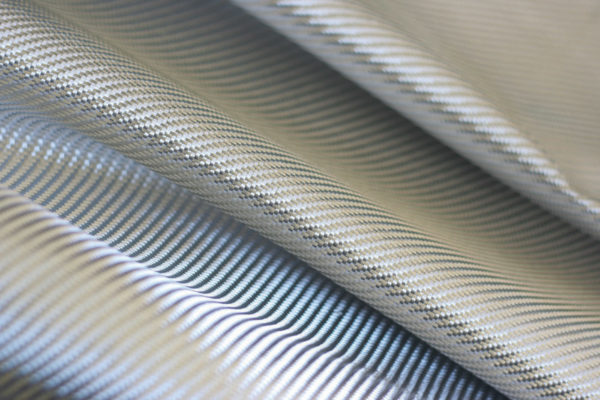

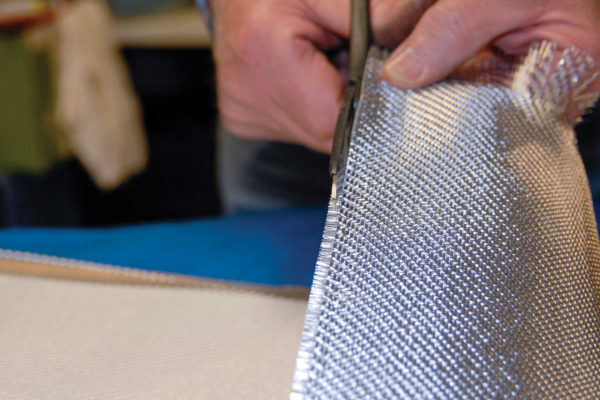

For the fiberglass part of the project, we chose a metallic fiberglass cloth called Barracuda aluminized glass fabric, which is the trade name for Texalium cloth made by BGF Industries. This material has the unique appearance of moldable woven aluminum with the working characteristics of high-performance fiberglass. Barracuda glass actually looks like a shiny, woven stainless steel when combined with resin, along with a clear gel coat that has been sanded and polished. It’s a nice, unique touch for any highly visible part of a project car.

Barracuda glass works substantially like standard fiberglass cloth and offers the same appealing features as fiberglass or carbon fiber cloth. Compared with creating parts out of metal (such as engine-turned aluminum, polished steel sheet or brushed stainless steel sheet), Barracuda glass is a fraction of the weight. The Texalium fibers in the cloth are polished to a high shine, which gives the product the look of braided stainless steel.

Be sure you always use clear transparent resins, although some light tint could be an excellent effect. Ditto for the gel coat: Do not use “neutral” colored gel. This would have a gray sheen that will ruin the shine of your part, which is exactly what you want to achieve in the first place when using this compelling composite.

Comments for: Bright Idea

comments powered by Disqus