Building a custom radiator cowling on a Cobra kit car

Story and photos by Dan Burrill

Cooling always seems to be an issue in replica builds for a variety of reasons. Perhaps the horsepower level is much higher than the original engine used. Or maybe too much airflow is lost going around the radiator, rather than through it. One way to address this inadequacy in airflow is by funneling it inside the grille opening by enclosing the cowl area.

An added benefit of this cowling is covering an unsightly hole between the bottom of the radiator and the body of the car. Doing so is a fairly quick and easy way to dress up your project car.

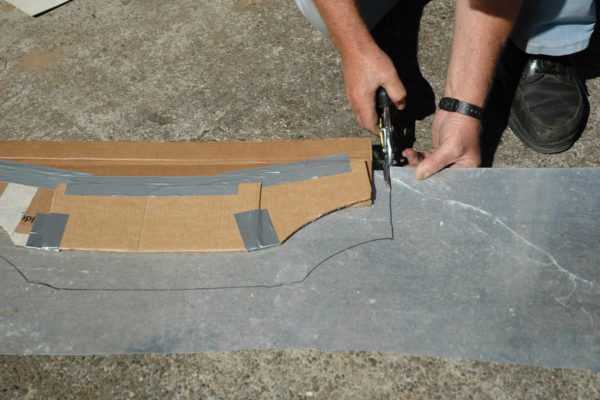

All you need are some sheets of cardboard and aluminum, available from most metal supply companies or even recycling centers. Comparatively speaking, aluminum is easy to work with. The key to a nicely finished project is to use cardboard templates to work out the design before cutting and bending the aluminum.

Note, too, that this functional enhancement can also be used as a way to dress up the underside of the fenders or hood, in the trunk, or on the firewall for a neat, clean look. While almost any car can benefit from this treatment, Cobra replicas in particular benefit from it due to the large gaping hole in the nose. As a side note, the original Shelby 427 Cobras used a pair of inefficient refrigerator fans to push air into the front of the radiator, rather than the more effective method of modern puller fan on the opposite side.

For this project, we used five pieces of aluminum: one for the opening at the top of the radiator, one for the bottom, one piece folded up on each side for the sides of the oil cooler (if one is used) and two pieces for each side of the radiator. More important than the materials, though, is that now this Cobra runs cooler and looks cleaner.

Comments for: Cobra Cowling

comments powered by Disqus