Docol R8 tube versus 4130 chromoly in chassis fabrication

By Dean Larson

You could build a chassis out of most anything and have it be strong with enough effort — remember Marcos built cars with a wooden monocoque? But most of us would rather just start with proven materials and get the job done, and for years, the standard has been 4130 chromoly steel. These days, many OEMs, racers and chassis builders are switching to a new material though, which has been engineered specifically for automotive applications. This new product is called Docol R8, a Dual Phase Advanced High-Strength Steel that exhibits key advantages over 4130 and mild steel in tensile strength, dimensional accuracy and tolerance to heavy fabrication. But what the heck does Docol R8 mean anyway, and are these advantages important enough to make the switch? Let’s dive in.

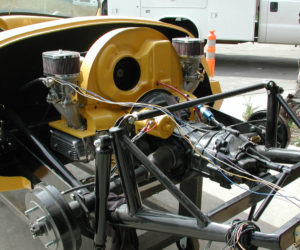

Here you can see how much cleaner Docol R8 is when compared to 4130 and mild steel.

What is it?

Docol R8 is an engineered high-strength steel tubing product designed especially for automotive and racing applications, named for its tensile strength of 800 MPa/116ksi. More specifically, it’s a low alloy steel that’s produced entirely from new (non-recycled) materials, which leads to a very clean and consistent product. The actual makeup of the product is not very easy to find, since Docol R8 is only made in Sweden and Finland, and only available through a small number of distributors.

What we do know is that Docol tubes are roll formed with a TIG welded seam, with both inner and outer weld beads removed. Docol is classified as welded tubing, but this weld is so well finished, that you’ll sometimes hear it referred to as seamless. Its chemical composition, as well as a lengthily quenching and tempering process in its slab form, leads to a highly developed microstructure, and favorable ductility, tensile strength and tolerance to welding and forming.

If all that sounds like gibberish, think of Docol much like 4130 chromoly steel — only better. The industry standard since the 1950s, 4130 is a low alloy steel comprised of chromium and molybdenum. It’s a tough material (with toughness defined as its ability to absorb energy and deform before fracturing) and exhibits high tensile strength. It can also be welded easily, but it’s important to note that chromoly should be heat treated after welding in these types of applications.

Docol starts to shine the minute you take delivery, as it’s way cleaner to begin with than 4130 or mild steel. It almost has a polished look to it, and it takes no more than a Scotch-Brite pad and some acetone to prep it for welding. It also has a far more consistent wall thickness given its roll forming process. Getting down to specs, Docol R8 outperforms 4130 chromoly in minimum yield strength (basically the amount of pressure required to deform a material) at 110,000 psi versus 75,000 psi. It also beats 4130 in terms of tensile strength (the maximum stress a material can handle before breaking) at 116,000 psi versus 95,000 psi. Docol R8 will also usually show a small advantage in elongation as well (defined as the increase in gauge length after the material has fractured, usually reported as a percentage increase over its original length) at 13 percent versus 12 percent.

Beyond its technical advantages as a raw material, Docol is easier to work with than 4130 and very tolerant of heavy fabrication. It’s clean to start with, as stated above, and it does not require any heat treating after welding. It stays ductile, even in the heat affected zone, and the material’s high consistency means it’s going to act the same every time you weld it, bend it or cause it to fail.

Talk about a tech overload, but to put it plainly, Docol R8 is easier to work with and will stand up to more abuse than 4130 will before it fails. And when it does, it holds on for longer because 4130 will fracture before Docol will. Engineers also like the fact that Docol fails in a predictable fashion (given its consistency in composition and wall thickness) as compared to 4130.

Working With Docol R8

We’ve been using Docol R8 for chassis work for a couple years now and found it to be a great product. You save a lot of time since the metal is so clean compared to 4130 or mild, and you can weld after using nothing more than a Scotch-Brite pad and some acetone. We notch it, weld it and bend it like any other steel, but have noted more spring back when bending.

For the welding shown in the photos, we’re using 1.5-inch, .095-wall R8 tubing. Like other materials, we move around when welding a chassis like this so as not to concentrate too much heat in one area. We’ve gotten our best results by jumping up to ER80S filler rod and putting our Miller Dynasty 400 on pulse mode at five pulses per second. Don’t feel left out if you’re a MIG guy though, as this material is suitable for both MIG and TIG welding.

Our Takeaways

After seeing the benefits of Docol R8 tubing firsthand, it’s what we use for the bulk of our chassis fabrication. If you’re a tried-and-true 4130 guy, I don’t expect to sway you so easily, but don’t be afraid to try it on your next project. Expect to pay around 12-14 percent more for Docol than 4130 though, given its advantages in performance and workability, but we believe that sorta comes out in the wash with the time you save in prep.

Learn more about Docol R8 tubing and its availability here at A.E.D Motorsport Products.

Comments for: Docol R8: A New Standard in Chassis Fabrication

comments powered by Disqus