3D printing provides a new source for rare metallic and composite…

Story and photos by Dan Burrill

Finding obsolete parts to keep an old car running or to restore a classic car has become a real challenge over the years. Now with 3D printing becoming more popular and widely available, this process has become a real boon to restorers and builders of classic replicas. 3D printing has been expensive in the past, but now more companies are offering the service, so it’s becoming more affordable.

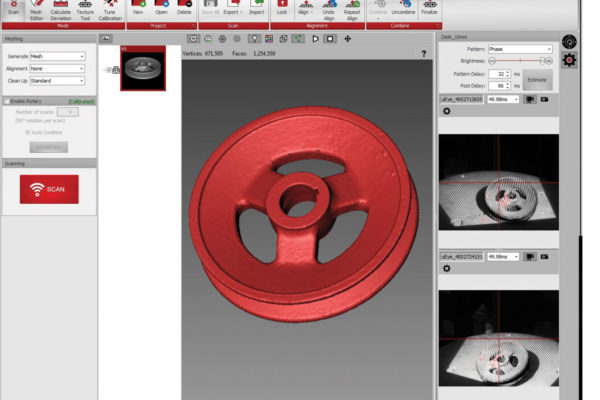

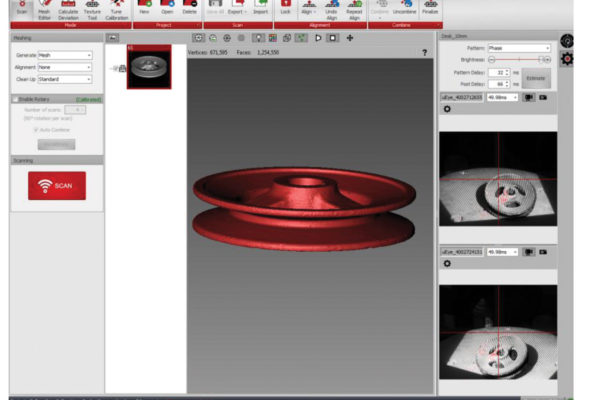

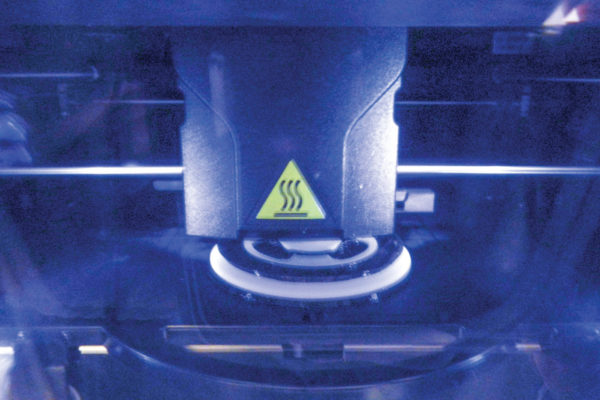

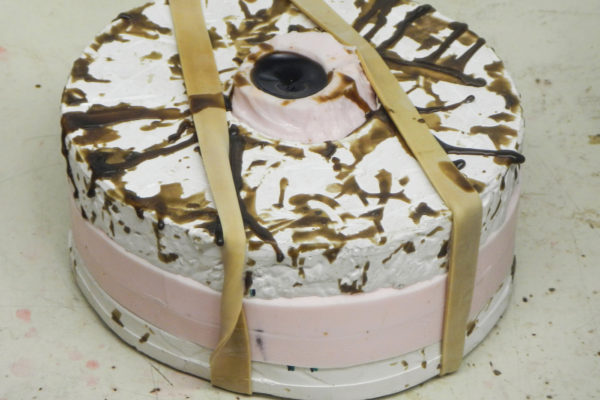

The basic process consists of material such as liquid molecules or powder grains being fused or solidified under computer control to create a 3D object. Objects can be of almost any shape or geometry and typically are produced using digital model data from a CAD file. Material is added up, layer by layer, until the part is complete.

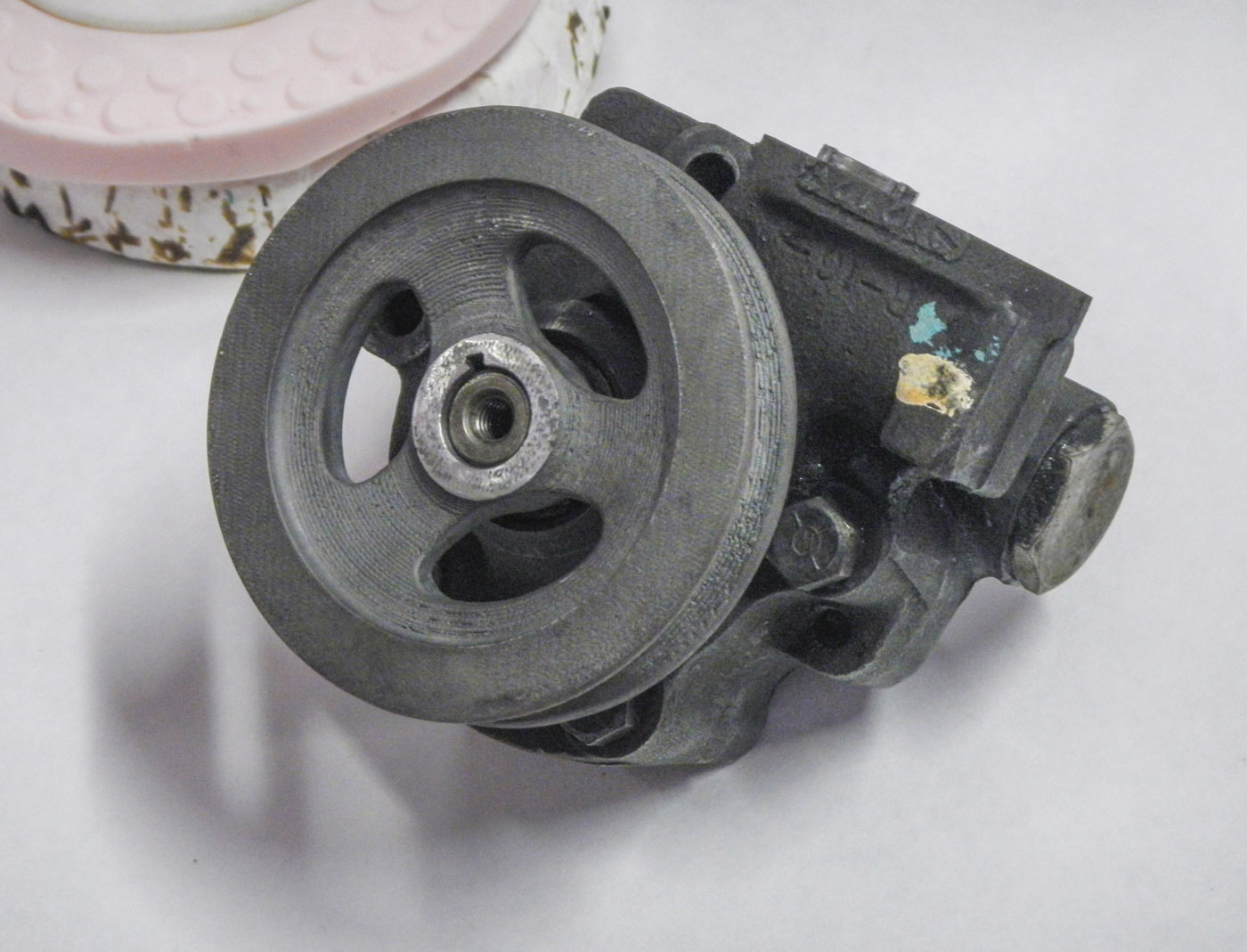

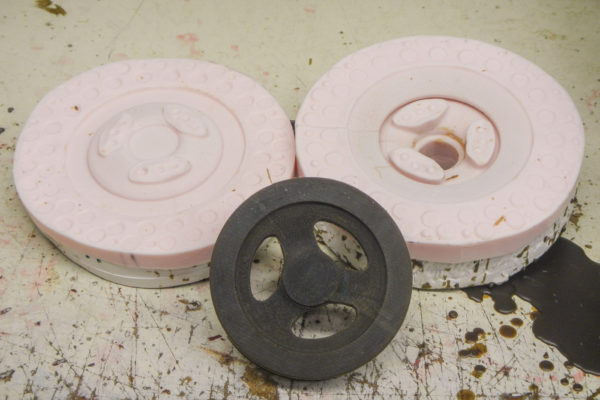

For illustration purposes, the part being produced here is a pulley from the air conditioning pump on an older Ford Thunderbird. Since this particular pulley is no longer available, we’d normally resort to scrounging the salvage yards or swap meets. Sometimes these parts can be found on sites like eBay, but that can be a hit-or-miss scenario. And even if you find one, you’d end up with an overpriced, old pulley that might crack and break as the metal fatigued.

So, we’ve decided to take an original part that we have in hand and create new ones using 3D printing. This approach can be used with just about any part that needs to be freshly fabricated. The process is digital magic. Simply photograph the old part in hand or, if it’s not readily available, draw a new one on the screen. Then follow the steps outlined below, and in the end, you’ll be holding the item in your hand.

Comments for: New Dimensions

comments powered by Disqus