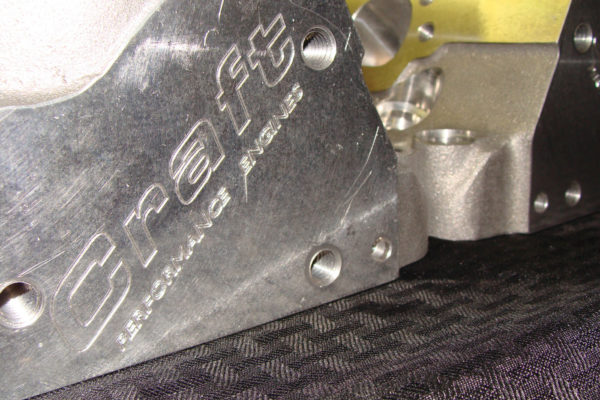

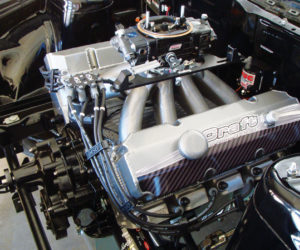

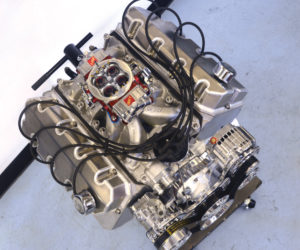

Craft Engines pulls big-block power out of a 465 ci small-block

Story by Steve Temple

Photos Courtesy of Craft Performance Engines

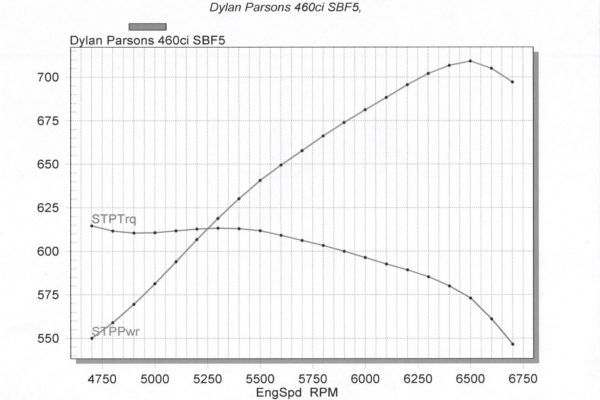

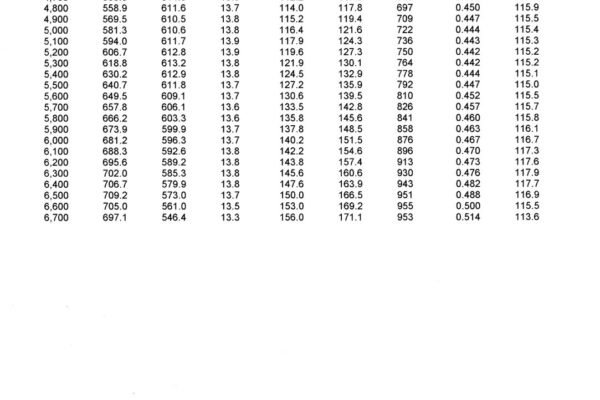

Some folks feel that you can’t pull more than 700 hp out of a small-block Ford, especially using a hydraulic roller camshaft, pump gas and a 20-degree wedge cylinder head. Well, just ask Lance Smith of Craft Performance Engines about that.

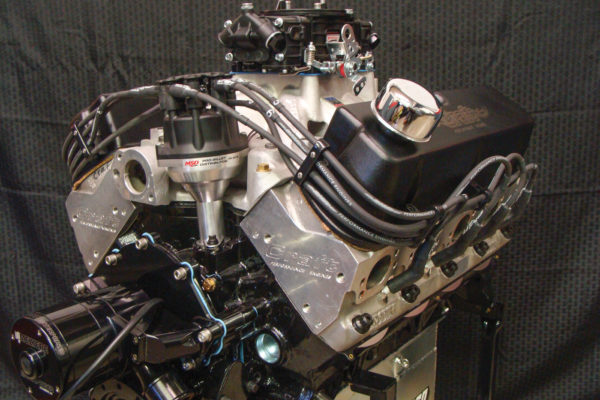

“We decided to take this head-on to see what we could do,” he says. And boy did they ever, as Craft hit that power level and then some with its new 465 Pro Street crate engine, which produces over 700 hp and 600-plus lb-ft of torque. Of course, not all road-going project cars might need this many beans. Everybody’s opinion varies as to what’s “streetable” — and this engine definitely runs at the wild end of that expression.

“When a guy is looking for 700 hp in this form, you have to understand what you are getting yourself into,” Lance admits. “It will definitely be a little more radical down low than most all our other crate engines.”

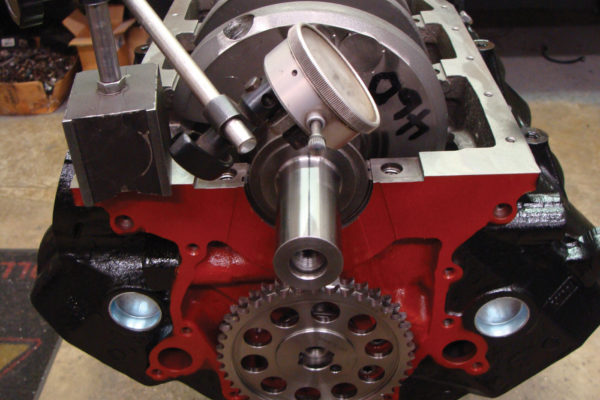

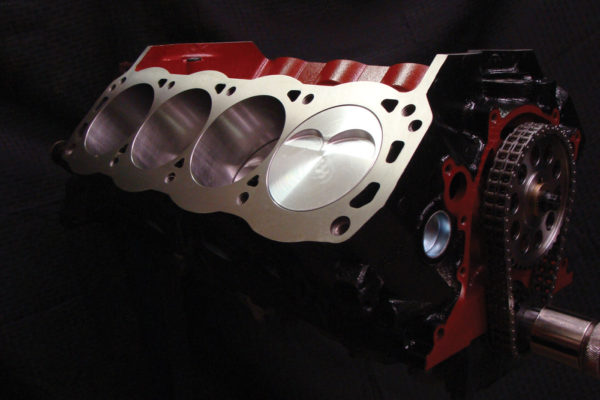

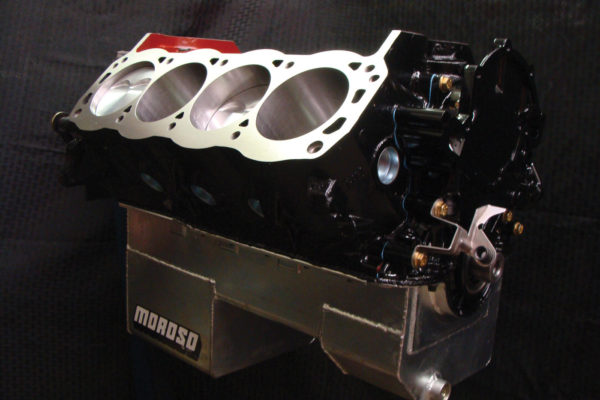

Digging into the details of this $16,000 mill, it costs about $4,000 more than Craft’s standard crate engine, but you get 100 extra horses for that upcharge. This high-performance option starts with a Dart 9.500-inch SHP block, which is then bored to 4.175 inches, and notched for a 4.250-inch stroke. Increasing the displacement from 351 to 465 ci requires a custom-forged crankshaft from SCAT Enterprises (predictably with a 4.250-inch stroke), which was electronically balanced to 0 ounces (neutral). Included with that were all the other necessary blueprinting and machining processes.

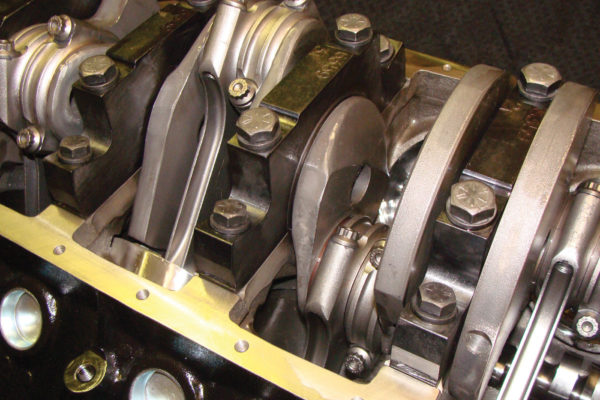

As for the connecting rods, they also came from SCAT, measuring 6.200 inches and notched for extra clearance. Craft went with Diamond flat-top pistons as the BRODIX heads are built with a very large chamber. These pistons were relief-cut to clear the larger valves and for the Total Seal 1.2-, 1.5-, and 3.0-mm rings. The metric ring pack is thinner than the conventional 1/16-, 1/16-, 3/16-inch set to enhance power output.

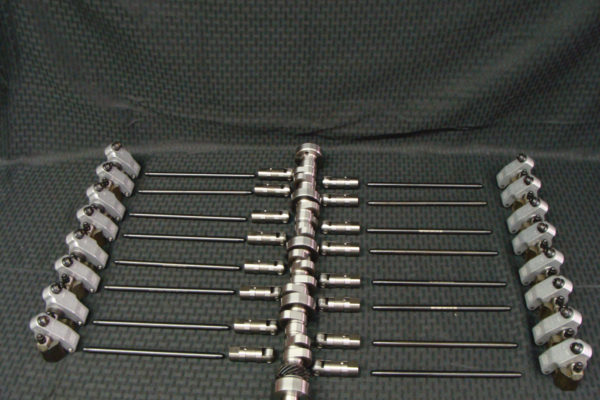

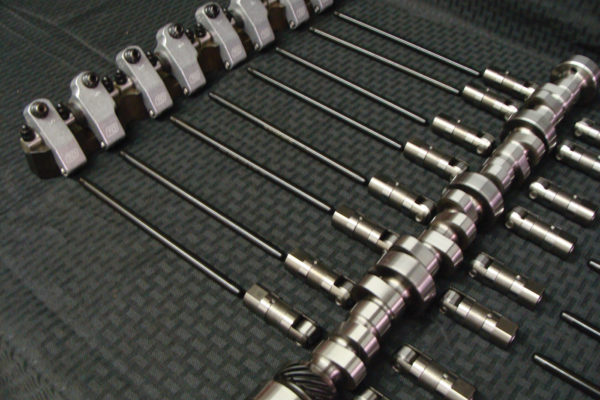

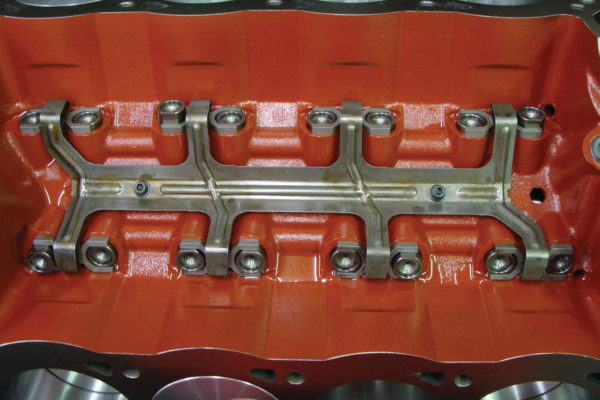

Regarding the valvetrain, Craft employed a custom-ground COMP Cams camshaft on a billet steel core. Not every item was special order, though.

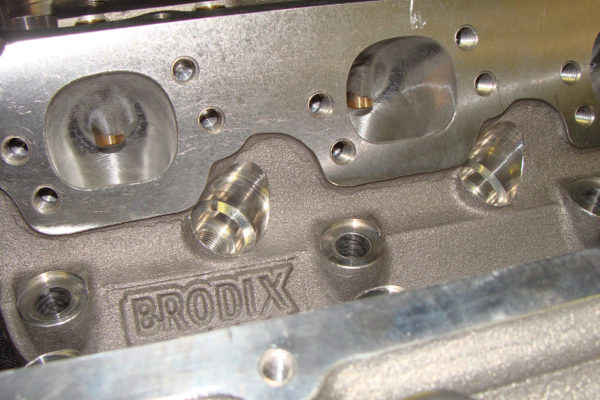

“We stuck with the standard Ford Racing hydraulic roller lifters,” Lance points out. “But we modified them for short travel, high-rpm operation. We used COMP Cams pushrods and the required T&D shaft-mount 1.7-ratio rockers needed for the BRODIX Track 1 RR heads.”

Lift on the hydraulic roller camshafts was limited, so that’s why Craft went with a 1.7-ratio rocker rather than the 1.6, in order to take advantage of the higher lift flow created by cylinder heads.

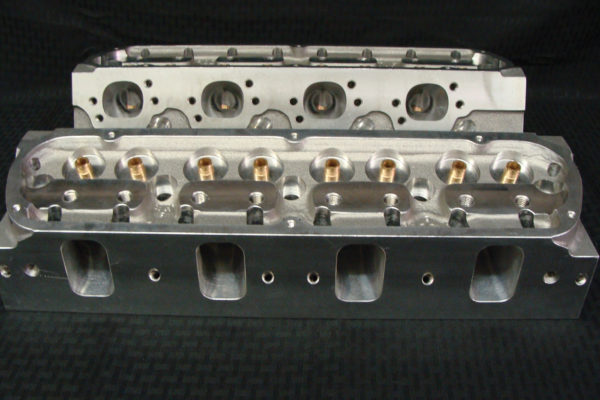

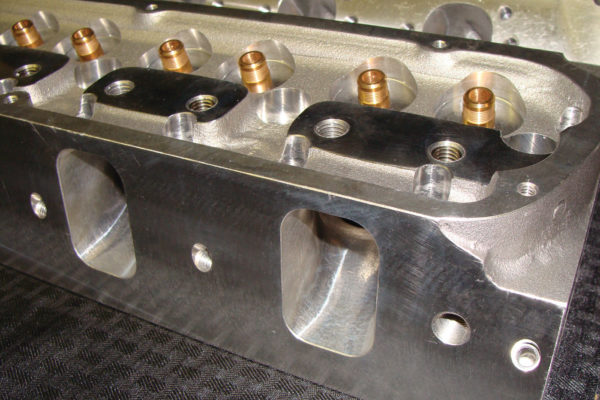

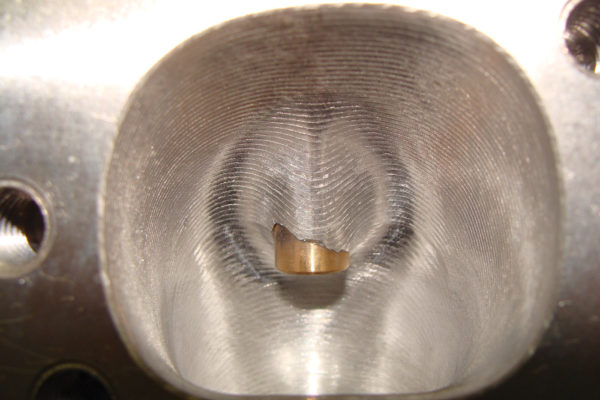

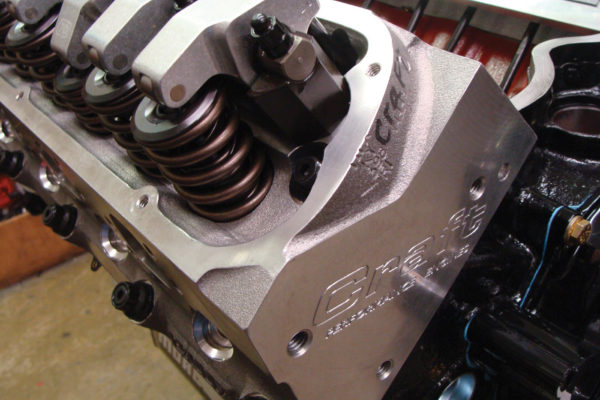

Craft’s technicians received the BRODIX Track 1 raised-runner cylinder heads as bare castings and then wrote a new CNC program that has the heads flowing 380 cfm on the intake side. These heads require an offset T&D rocker since the intake runner location has been moved. In addition, the chambers on these heads are pretty large, with 255 cc intake runners and 80 cc chambers, so Craft was able to stay with a flat-top piston — even on a larger cubic-inch engine.

These units are raised a little, of course, as most performance aluminum heads are. Because the engine boasts 465 cubes and runs hydraulic rollers, there is nothing crazy required for valvetrain components in the heads.

“We stayed with a one-piece stainless valves (2.14 inches on the intake side and 1.57 inches on the exhaust side), steel retainers, COMP Cams springs with a little more than usual spring pressure,” Lance notes. “Just for the possibility of higher revs with the hi-rev lifters.”

How about the exhaust system? “A guy doesn’t have to get too extravagant on the headers,” Lance notes. “You can use a 3-inch bolt spacing on the flange, but it will need to have a 2-inch primary to avoid covering the exhaust ports.”

For this build, Craft bolted on an Edelbrock Victor intake manifold (kind of big for most Windsor engines, but it worked great for this project). Because of the size of the intake runners on the heads, the intake manifold had to be completely ported to keep from becoming a restriction. Since the intake has a raised runner end, rail spacers are used under the intake (similar to the Victor Race heads) in order to fill the void between the block and intake.

To top it all off, “We are big fans of the Quick Fuel carburetors, so we used their Q-Series 950 cfm carb,” Lance adds. That proved to be ideal, as indicated on the dyno sheets. The engine pulled 955 cfm at max output of 709 hp.

This customer’s application is a 1989 Mustang, and he wanted to use an electric water pump and a rear-sump pan, even though the engine will typically use an Edelbrock mechanical water pump and a front-sump pan for Cobras and early Mustangs.

We’re eager to see how well this overachieving stroker motor works in other applications as well, so let us know if you slip one between the frame rails of your next performance project.

Comments for: Numbers Game

comments powered by Disqus