Kaase’s Boss Nine Engine

By Ro McGonegal

Even though Ford has produced some of the most exotic engines in car builder history, none of them exist today in their original form. One of them has just been revived, however, in a form that’s just as cool, just as intimidating—and with a soul and disposition for modern times.

That’s because the biggest negative about the original Boss 429 engine was the size of the intake and exhaust ports. Their volumes were so large that they didn’t produce viable velocity until the airflow reached the upper rpm band. In short, it was an homologation special, built to satisfy minimum production numbers in order that it be legal in certain racing organizations.

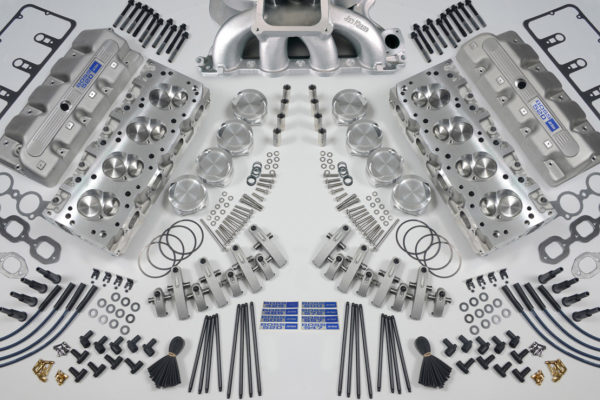

Jon Kaase Racing Engines (JKRE) in Winder, Georgia, husbanded this racing remnant a few years back and decided to go full steam and make the Boss Nine fully effective for street and recreational duty. For aspiring engine builders, Kaase supplies all the parts needed to build a Boss Nine. Alternatively, you can order a fully assembled dyno-tested unit. Whatever your project car—street rod, Cobra replica or vintage street machine—the company offers a trio of cylinder blocks from which to choose: stock Ford 429, Ford SVO cast iron, or Ford SVO cast aluminum.

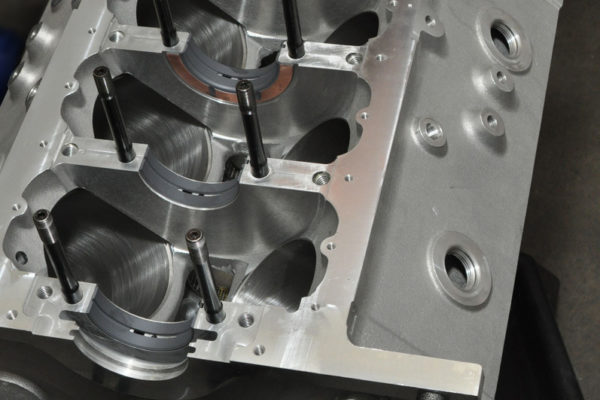

Though more expensive, the obvious advantage of a cast-aluminum Boss Nine engine is that it weighs much less than its cast-iron counterpart. It also features ductile iron cylinder sleeves that are pressed into the alloy block. This formula removes the potential threat of coolant in the water jackets making contact with the cylinder liners, thus eliminating certain corrosion troubles.

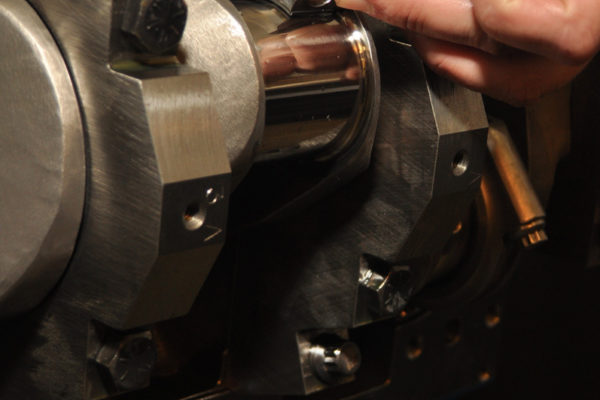

To build more cost-effectively, the production passenger car 429 cylinder case is the answer. With a 0.030-inch overbore and a 4.300-inch stroke crankshaft (Scat has an abundance of these particular units), the tally becomes 520 cubic inches. Another plus for the BB Ford is that the crankshaft has sufficient clearance to allow a long stroke to function without altering the location of the camshaft, even with a 4.50-inch stroke or 600ci.

JKRE offer the following stroke lengths: 3.850, 4.125, 4.250, 4.300, and 4.500 inches. Though the popular cylinder bore choice is 4.390 inches, they go larger. This is accomplished by Ford’s SVO aftermarket blocks that have the capacity to provide 4.600-inch bores. These bigger blocks feature siamesed cylinder cases—there are no water jackets between the cylinders—and cooling is effected on the inside and outside flanks.

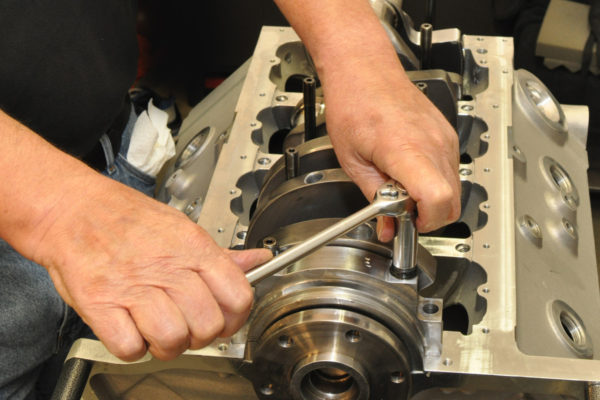

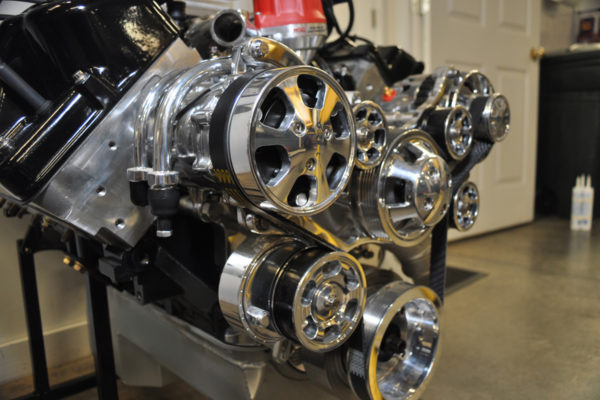

Displacement tops out at 605ci, but the most popular combination is one for 520 or 528 cubic inches. Oiling is available in wet- or dry-sump configurations, but street runners usually forgo the dry-sump arrangement because it adds complexity and avoids the hazards of public roads (a stone wedged between drive belt and pulley, for instance).

Even so, a dry-sump system adds 40 horsepower to the total versus a wet arrangement. The wet sump features a one-way mesh screen bolted to the sump, along with a ¾-inch wide metal scraper mounted at the top of the mesh screen and running the length of it. In addition, two one-way trap doors in the sump itself maintain a deep reservoir of oil around the pick-up during hard braking.

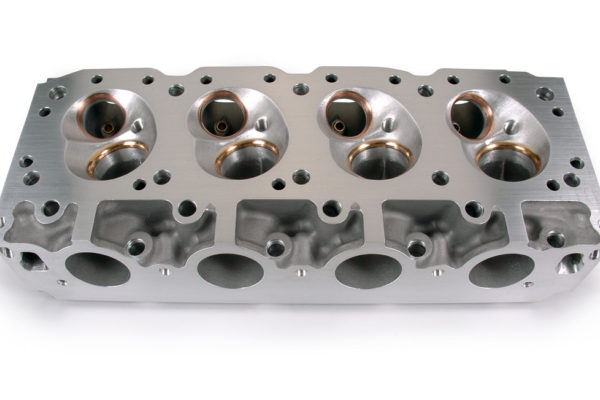

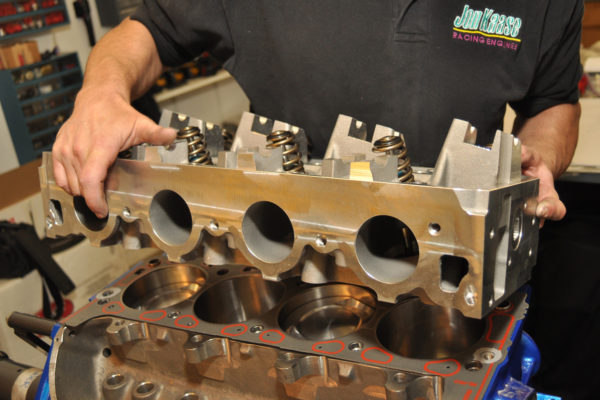

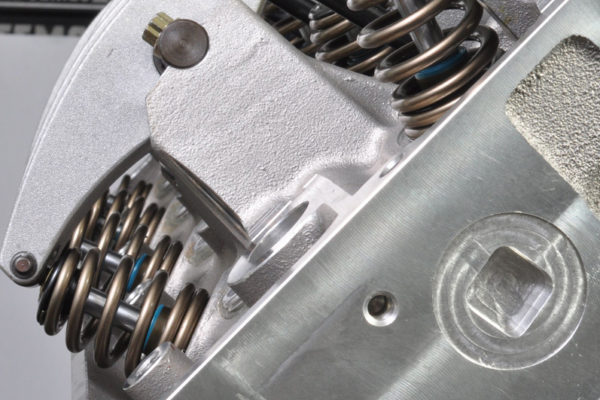

Because original Boss hemi heads are as scarce as lips on a chicken, Kaase opted to produce his own, infusing them with modifications for increased drivability, low-end response, and a tranquil 700 to 800rpm idle speed. The heads have a 5/8-inch thick deck surface that can easily accommodate very high compression from whatever form of forced induction you prefer.

Once the fine-tuning is accomplished, the 521-inch engine can deliver anywhere from 450 to 800 horses on pump gas. That’s more than enough ‘crank’ to blow your bantam-weight three-window into the middle of next week.

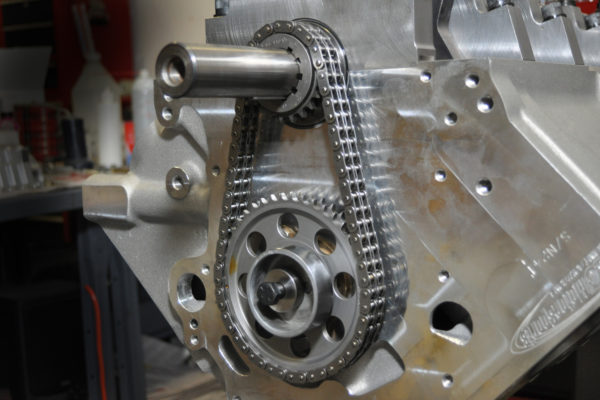

Adjunct to the revamped cylinder heads, the miracle of technology runs rampant in the camshaft department. Be aware that camshaft duration must not go beyond 240 degrees, lest manifold vacuum be severely compromised and require a booster or canister to retain it. Kaase’s Boss Nine depends mostly on the lobe separation angle and multi-phased hydraulic roller camshaft for low-speed response, as well as a smooth transition from idle speed to fully open throttle. Altogether ideal for chugging through town or idling merrily around the show-ground venue.

Mounting the Boss Nine can be done either by a motor plate (to make the drive-train angle as straight as possible) or with usual mounting hardware. The front of the standard Boss 429 engine sits four degrees up, with a corresponding angle on the manifold boss to keep the carburetor base horizontal. Induction choices are plentiful, ranging from the usual single 4-barrel (4150 or 4500 series) on a single-plane intake, a tunnel ram set-up, a roots-type supercharger, Hilborn stack injectors, or a Wilson 1388cfm 4-barrel throttle body injector, as shown here.

Back in the late Sixties, two Boss Snake prototypes were built at Kar Kraft’s Brighton, Michigan, facility, using the Boss 429 body, the front clip (minus the scoops) and taillights and exhaust treatment from a Shelby GT500, and a Cougar dashboard. Kar Kraft, you may remember, is the same outfit that raised the 427 Thunderbolt drag cars.

Fast forwarding from then, Jon Kaase released the first Boss Nine hot rod engine about four decades later. So what’s old is new again—and now set up for the street.

Comments for: SEMI-HEMI

comments powered by Disqus