Installing an in-tank fuel pump and sending unit

Story and photos by Jim Youngs

Seems like everywhere you turn these days, car-wise that is, there’s more and more talk about electronic fuel injection. And more and more new EFI systems are coming to market. So it shouldn’t be much of a surprise that more car builders are taking advantage of their benefits. These include easier cold starts, stable idling, smoother throttle response, accurate adjustments for temperature and changes in air pressure, along with decreased maintenance and better fuel efficiency.

We’ll save a discussion of the various types of aftermarket EFI systems for another time, but suffice to say there are a couple of support items that will also need to be addressed when considering an EFI setup, whether you are swapping from a carburetor or starting out with EFI from the get-go.

Most important perhaps is considering the fuel-delivery system. Unlike a carburetor that delivers atomized fuel to the engine under relatively low pressure, EFI systems rely on an injector to atomize fuel under much higher pressure, typically around 40 psi. That’s why most modern EFI systems on production cars use high-pressure fuel pumps mounted inside the fuel tank.

There’s an old mechanic’s adage that says, “Most fuel pumps are designed to push fuel instead of pull fuel,” which I interpret to mean that they perform better at pushing fuel to the induction rather than pulling fuel up from a tank, and then pushing it toward the induction. Granted there are exceptions to this truism, and

companies that offer inline fuel pumps to serve EFI

applications. But our personal experience in trying to use inline pumps with EFI is less than stellar. In contrast, we’ve had excellent results using in-tank pumps for both throttle-body and tuned-port EFI applications.

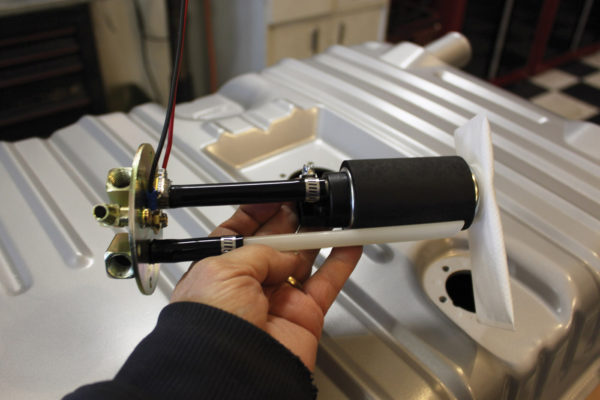

One other important consideration in an EFI fuel- delivery system is the required reservoir tray inside the gas tank. This tray is designed to prevent an in-tank fuel pump from starving for fuel. Companies like Tanks Inc., maker of the fuel tank shown here, offer these trays built into their tanks. This company also offers a retrofit fuel pump module (PA Series) that includes the tray for those who want to use an original fuel tank for an EFI swap. These modules additionally include accommodation for a return line and vent.

As an illustration for how to install an in-tank fuel pump, we turned to Tanks Inc. for one of its EFI-ready steel tanks for one of our project vehicles. Though this particular tank is for a vintage Chevy, the procedures you’ll see here apply to almost any specialty car EFI fuel system.

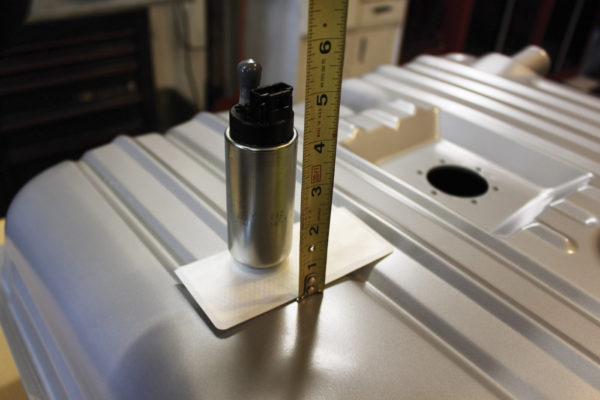

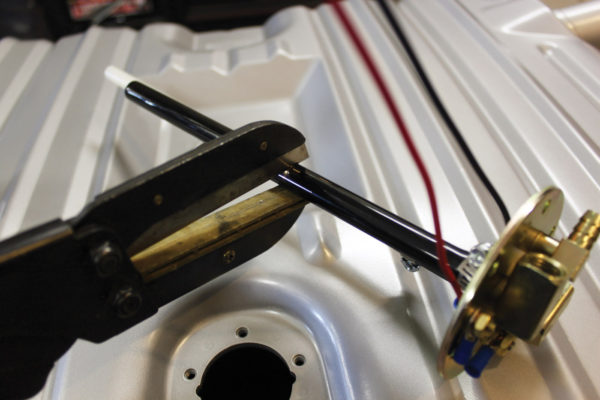

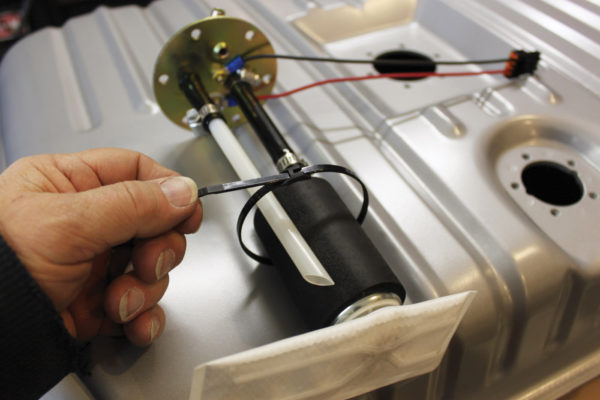

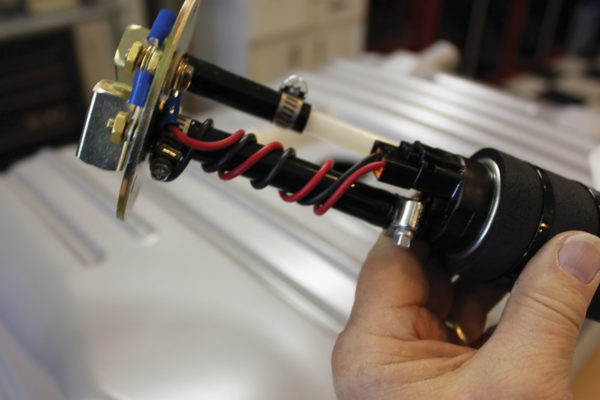

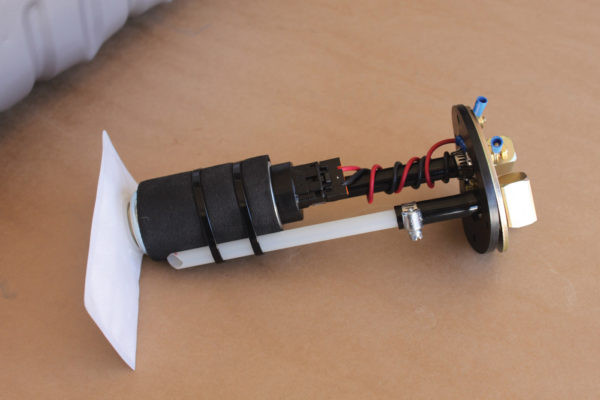

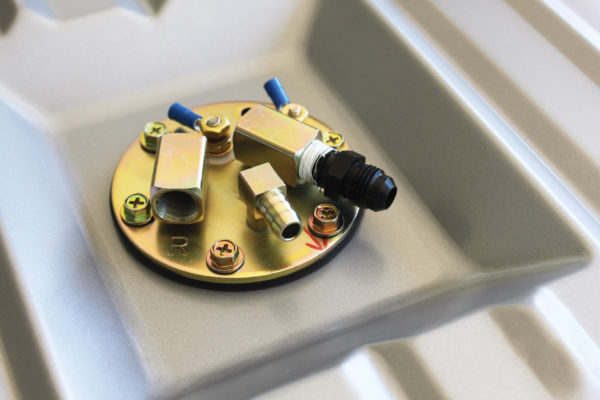

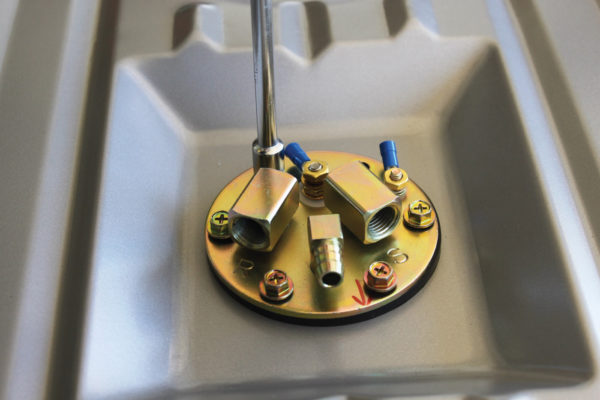

In addition to the Tanks’ fuel tank, we also opted for Tanks’ GPA-2 in-tank fuel pump module rated at 190 liters per hour (about 54 gph at 40 psi or 48 gph at 60 psi), enough to feed a 450 hp engine. The modules incorporate 1/4-inch NPT supply and return line fittings, barbed vent fitting, an in-tank wiring harness, filter sock, insulator sleeve, gaskets, hardware and genuine Walbro fuel pumps, and are available in a wide range of flow and horsepower ratings.

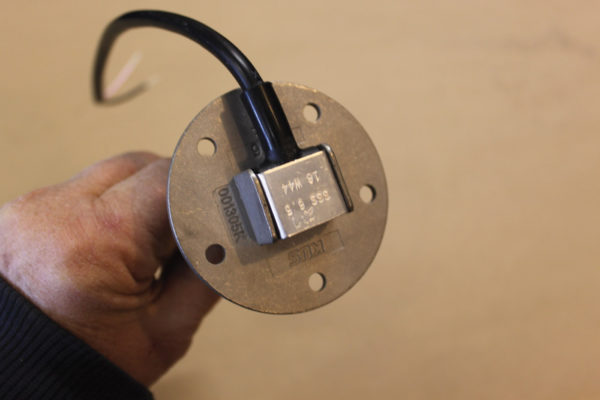

While readying this new tank for a new engine and EFI induction, we also decided to look for a sending unit alternative, since the gauge on this particular car had never worked properly. We’ve never really trusted those spindly, problematic swing-arm sending units, so for an alternative we found something promising in a KUS shaft-style sending unit from WEMA USA (in this case a 6.5-inch tube length, $55). These units are stainless steel and are a direct replacement reading from 240-30 ohms range.

The install procedure was simple. Measure the depth of the tank through the sending unit hole, subtract an inch and place the order for the closest tube length needed. When it arrives, position the gasket and mounting plate over the mounting screw holes and screw it down.

During our research for this fuel tank and pump, we also ran across a nifty item from Speedway Motors, a fuel gauge interface module ($129.99) with adjustment, which allows any sender to work with any fuel gauge. Through a combination series of DIP switches, you can match up any resistor output of the sender with any gauge, and even adjust the included potentiometer until the gauge needle aligns where you want it.

Comments for: Tank Tech

comments powered by Disqus