Coilover shocks provide precision adjustability and curb appeal

Story and Photos by Jeff Zurschmeide and Courtesy of Cusco

Chassis tuning can take quite a bit of time and even more money. But with a little advance knowledge, the savvy builder can cut some time, cash, and even sweat and tears out of the suspension development process. The goal is to get it right the first time, rather than going through multiple setups in a trial-and-error process.

“If you end up replacing the first set of dampers you buy, that was a very expensive lesson,” advises technical expert Wyatt Gilbert of Motion Control Suspension. “I’m a firm believer in doing it right and doing it once.” What does that involve?

“What we do with a shock absorber is to fine-tune the mechanical grip that the car is able to generate,” Gilbert explains. “It makes your tire’s contact patch more efficient. Without a proper set of dampers controlling a spring, you have an uncontrolled chassis. It’s not compliant over bumps and has a tendency to do things that are fast and uncomfortable.”

What do these terms refer to? “Fast and uncomfortable” can mean anything from bouncing the driver to launching the whole car into the air and crashing spectacularly. While these driving events might make for a great YouTube video, it’s hardly the stuff of performance handling. Keeping a chassis from getting unsettled starts with a fundamental understanding of dampers.

What the dampers do is resist the bouncing motion as a car’s tires traverse various bumps and dips, smoothing out the movement over time. Without a damper, a single bump will echo, repeating its effect as the spring bounces. The damper, however, turns that into a single compression and extension by turning the motion energy into heat. Damping keeps the chassis steady and the tire in contact with the pavement — where you want it.

How do you choose the right dampers for your project car? After all, they look pretty much the same on the outside. And they all work by forcing oil through an orifice in a piston sliding inside a tube. The oil can’t go through very fast, and that creates the damping resistance. Also, most shocks today have some inert compressible gas like nitrogen in the tube to pressurize the system. But that’s about where the similarities end between top-quality dampers and bargain-priced units.

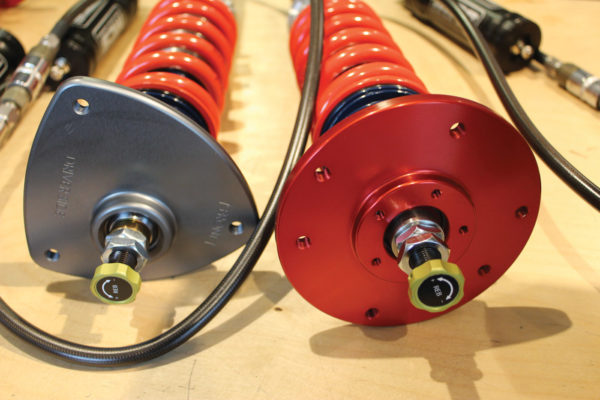

The thing that differentiates a true performance setup from a basic unit is adjustability. The ability to adjust that resistance is where the performance comes in. You can buy single-adjustable dampers that adjust resistance in one direction, usually extension, or which adjust both compression and extension resistance simultaneously. Double-adjustable dampers allow you to separately adjust the resistance to compression and extension.

Really high-end dampers can be adjusted three or even four ways, with separate settings to handle high-speed motions such as going over train tracks and lower-speed motions such as pitching forward under braking. In both cases, the speed being described is how fast the wheel is moving in relation to the car, not how fast the car is driving.

An added adjustment with premium dampers is that they often have a threaded body that allows you to adjust the total height of the assembly, and also to replace the car’s springs easily with firmer or softer units. Total height adjustment allows you to maintain full suspension travel capability while achieving the ride height you want.

Advanced drivers use ride-height adjustment to control the amount of weight placed on each tire. Equalizing the weight on either side of the car helps the car turn equally well in either direction. Note that when you adjust the ride height of any car, you should always realign the wheels afterward. Small changes in ride height can have a dramatic effect on steering.

One of the best benefits of choosing a coilover suspension for your project is that you can choose the spring rate you want. (Spring rate is generally expressed as the amount of weight required to compress a coil spring 1 inch.) You can change spring rate relatively easily, but there are trade-offs. “When you put a heavier-rated spring on a car, you’ve got to use more damping to control how fast, or how violently, that spring is going to load up and unload,” Gilbert points out.

Choosing the ideal spring rate for an application comes down to half science and half personal preference. For reference, a typical Cobra weighs about 2,200 pounds or so, with 53 percent on the front axle and 47 percent on the rear. Doing the math, that’s 1,166 pounds on the front and 1,034 pounds on the rear axle. These cars often run with 8-inch-tall, 350-pound rear springs for solid axles and 500-pound springs in front. Cars driven on racetracks usually use firmer springs, while street cars are better with softer rates.

There are so many variables that it’s best to consult the supplier for recommendations. As one example, QA1 offers extensive website resources for most popular models, and by weight. The company also offers a range of shocks and struts in several different valving configurations to suit individual ride conditions, whether for the street, strip or road course. Overall, getting a top-shelf suspension set up properly, corner-weighted and adjusted for the spring rate in use usually requires specialized equipment like corner scales and an alignment rack.

“People think that a stiff car is a fast car,” Gilbert says, “but the fact is that you need some compliance. If you have too many things to adjust, it’s easy to make the car too stiff, which hurts your handling.”

Most builders seek out a qualified and well-regarded shop to do the work and to ask their advice before spending any money. And doing some on-road testing helps as well. “One of the things I encourage people to do when they’re shopping for dampers is to go drive a car or ride in a car that’s already got a particular set of dampers installed,” Gilbert suggests. “Compare the options you’re considering and let that be the ultimate metric for what value is added.”

Lastly, what about remote reservoirs? Their purpose is to provide additional oil and gas volume, which helps keep the shock cool and consistent over time. Keep in mind that a shock’s main purpose is to convert kinetic energy into heat energy, and the better it does that, the better your ride and handling will be. That’s why the 4x4 owners love them, since they’re beating the hell out of their shocks all the time. Similarly, on-track endurance racers in events like the 25 Hours at Thunderhill, or the Rolex 24 at Daytona need something that stays consistent over long periods of constant action.

For the typical street car builder, the main advantage comes if you don’t have convenient access to adjustment and you want to make frequent adjustments. Many cars don’t have ready access to the shock top in the rear. So if you want to make frequent adjustments, a remote reservoir shock makes that easier, all for optimizing both the ride and handling.

Comments for: The Case for Coilovers

comments powered by Disqus