Ode to the Small Block Chevrolet

By Dean Larson

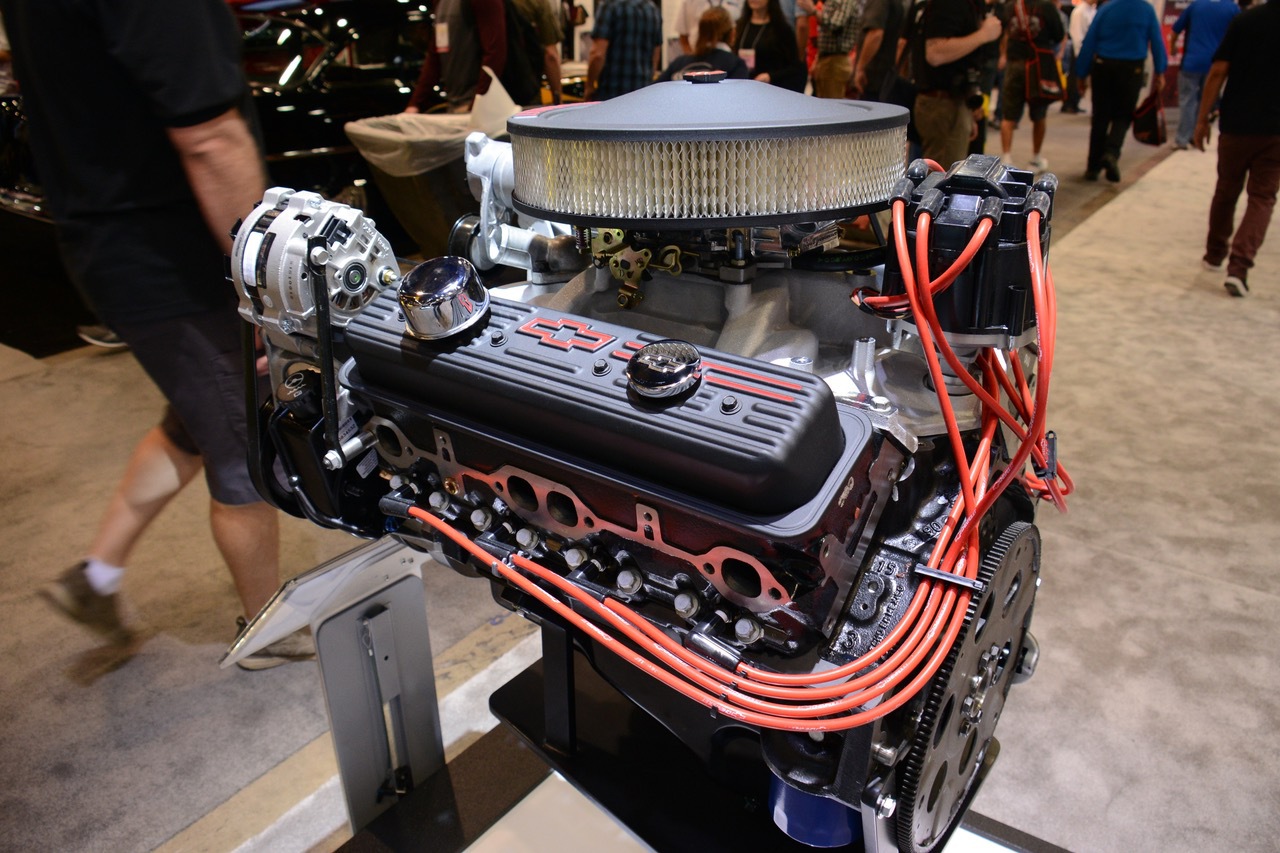

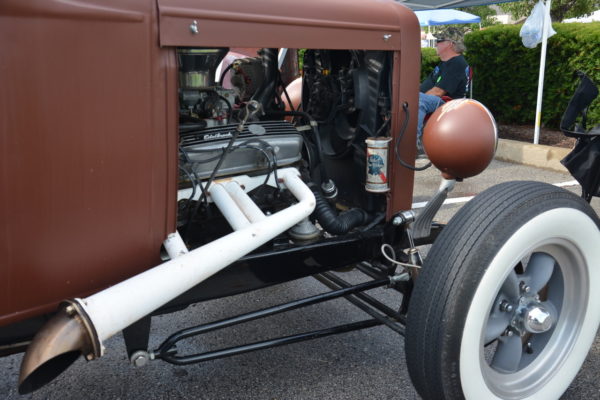

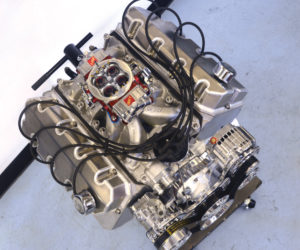

In a world of plentiful LS swaps and factory supercharged LT4 crates, the old small block Chevy doesn’t get the love it used to. It’s no powerhouse in stock form, but there are a million old grease-covered SBCs still out there today clacking along and powering everything from old dump trucks, to Monte Carlos and badass big bore class racers. It might be old school, but it’s tried and true, and is without a doubt one of the most significant production engines ever. With these accolades in mind, lets take a quick look at what makes the small block Chevrolet engine great.

The small block Chevy name refers to Chevrolet’s V8 engines from 262 to 400 cubic inches built between 1955 and 2003. The SBC was not Chevrolet’s first V8 though. That’s an honor that belongs to the 36 hp OHV engine from the 1917 Series D. (Fun fact: The Series D was ranked number 11 on Edmunds.com’s list of the 100 Worst Cars of All Time.)

The original small block Chevrolet was the product of impeccable timing and great minds coming together. There was an explosion of technology available after World War II, and the American people were hungry for more V8 engines. Chevrolet had its overhead-valve technology down to a science, but had not made another stab at an OHV V8 since the disastrous Series D.

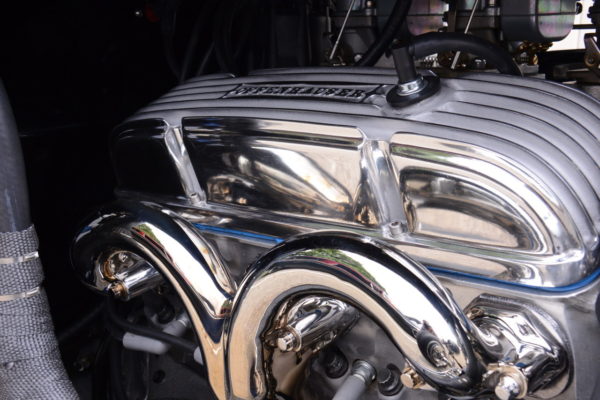

Ed Cole, serving as a chief engineer at the time, is most often connected with the development of the small block, but a few other prominent automotive minds had a hand in its development. Zora Arkus-Duntov was well versed in OHV designs and valvetrain technology, proven by his Ardun OHV conversion for the Flathead Ford, and helped Cole perfect the camshaft and valvetrain design. Notable hot rodders Smokey Yunick and Ed Iskenderian also flexed their performance backgrounds to help Cole’s team fine-tune the SBC’s design and improve durability and performance. The initial version of the small block went from the drawing board to production in just 15 weeks.

New for ’55, the 265 ci “Turbo-Fire” V8 served up 162 horsepower in a compact package that was easy to work on. The initial iteration had some weaknesses, (namely the “optional” oil filter) but the engine had room to grow and improve within its footprint. By increasing the bore and stroke slightly, Chevrolet was able to pull more and more power from the SBC platform while retaining the majority of its design. By the dawn of the muscle car era, GM was regularly extracting over 300 hp from its small blocks.

Another step in the small block’s evolution was the introduction of the Ram-Jet Fuel Injection system available for 1957. Better known as Rochester fuel injection, this mechanical continuous injection system boosted the economy, performance and drivability of Chevrolet’s 283 cubic inch V8s (if properly maintained). With the Rochester system installed, the small block Chevy became the second engine to boast one horsepower per cubic inch. Chevrolet continued to offer the Ram-Jet option in Corvettes up until 1965. In its final 327-ci version, the injected small block Chevrolet produced 375 horsepower.

Despite being saddled with increasing smog equipment, stringent economy standards and decreased compression ratios, the small block lumbered on through the ’70s, ’80s and ’90s, having powered just about every vehicle line in the GM fleet at one time or another.

So I lied a bit, there aren’t a million old greasy SBCs running around today. There are probably much more than that, because as of November 2011, over 100,000,000 small blocks had been built since 1955. And while trusty SBC was finally phased out in 2003 by the LT and LS engines, brand new Chevy small block crate engines are still rolling off GM’s Toluca, Mexico production line today.

Design

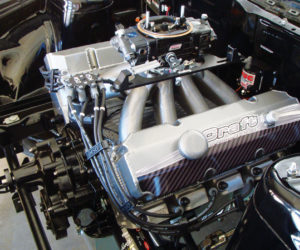

There are a few basic factors across all small block Chevys that make the engine work so well. While the most interesting attributes come down to engineering, it’s impossible to overstate the roll of simplicity. A simple engine, with simple maintenance and standardized parts goes a long way under the hood (pun intended). But simplicity isn’t the only factor, or GM would have stuck with the straight six, so here’s a breakdown of some SBC’s notable design strengths.

You can nearly tell the whole story of the small block Chevy with a discussion of bore and stroke. The SBC was built using several bore dimensions ranging from 3.500 to 4.125 inches. Several stroke dimensions were used also between 3.000 and 3.750 inches, but every small block Chevy was built in an oversquare, or short stroke, design. This means that the cylinders have a greater bore dimension than stroke length, which yields a bore/stroke ratio greater than 1:1.

An oversquare engine has a few huge advantages compared to square (1:1) and undersquare (less than 1:1) designs, namely better qualities at high rpm thanks to improved aspiration and less stress on the rotating assembly. This allows the engine to rev more freely and do so with less piston speed.

The larger bore dimension also means that oversquare engines can utilize larger, or more valves, which leads to more efficient cylinder head designs. The increased surface area between the piston and head promotes better engine cooling also. Thanks to its shorter stroke, oversquare engines generally have shorter connecting rods, which gives the engine a shorter overall height.

For its benefits, the oversquare design has few faults. The oversquare orientation favors higher rpms for making its peak performance numbers, which isn’t ideal in all cases. For its larger bore dimension, the larger combustion chamber can also lead to inconsistencies in combustion and higher emissions.

A few other important qualities were built into the original SBC design beyond bore and stroke. The hydraulic lifters used in the SBC self compensate for valvetrain clearances and don’t require the level of maintenance solid lifters do. Simple stamped steel rocker arms were mounted on spherical pivots for improved valvetrain motion. The SBC’s oiling system was also more than up to the task of high rpm operation. While it oils the camshaft journals before the main bearings, it has been found effective, even in high performance applications.

With more than 100,000,000 small block Chevys built since its introduction, it’s plain to see the engine has earned its keep on America’s race tracks, job sites, farms and interstates. The engine is a staple in the collector car scene across the globe and will remain a viable option for daily driving, hot rodding and racing for years to come. Any good list of the best engines ever will surely hold a spot for Chevrolet’s small block as long as the internal combustion engine reigns supreme.

Photos: (in order of appearance)

-By priceman 141 - Chevrolet 307 V8 Turbo-Fire Engine, CC BY 2.0, https://www.flickr.com/photos/...

-By John Lloyd - Very First Chevrolet Small Block Built, CC BY 2.0, https://www.flickr.com/photos/...

-By Dean Larson

-By Jeff Bruss

-By Dean Larson

-By Dean Larson

-By Thilo Parg - Own work, CC BY-SA 3.0, https://commons.wikimedia.org/...

-By Dean Larson

-By Dean Larson

Comments for: Ode to the Small Block Chevrolet

comments powered by Disqus