RCN Windsor Build Part 6

By Dean Larson

Tag along with us for the next couple months as a pair of total amateurs tackle the complete rebuild of a Ford 302 Windsor engine. Despite being obsessive gearheads and project car addicts, neither of us have ever rebuilt a car or truck engine by ourselves before. Our subject is a bare Ford 302 engine from around 1972 that we picked up from a shop for cheap. In the end, we hope to come up with a fun and reliable Windsor engine that any guy could build at home with a few helpful resources. Will we prove to be Windsor wizards, or will this thing kick out a rod immediately? There’s only one way to find out.

Thinking Out Loud

I think it’s fair to say there are three different types of “engine builders” out there. First, there’s the shadetree mechanic who can take something apart, clean it up and put it back together (successfully). Then you have the guy who can rebuild something and hop it up some and achieve good results. Finally, you have the top echelon, the guy who can dream up specific engine combinations for specific goals — say a nice streetable Ford 408 ci stroker that makes 500 plus lb-ft under 4,000 rpm. Really the point to all this is to set the stage for what I’m trying to do right now, which is plan out an awesome streetable combo for our 347 stroker like a top echelon engine builder would do, all while operating with a type one shadetree skill level.

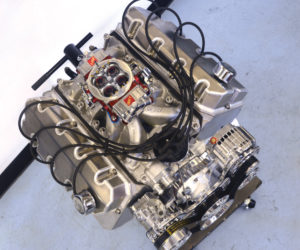

I probably could have been thinking about this earlier and had parts ordered, but I guess it's a classic case of out of sight, out of mind. But our engine is back now, and it’s FINALLY time to get back to the build and plan out our next steps. As a quick reminder, we sent our Ford 302 ci block out to the machine shop after we did some initial prep work, and that was probably three months ago. They said it would be about three weeks to get the block decked, line bore the mains, finish-hone the bores and install our cam bearings. While they were at it, we had them throw in some ARP fasteners on the mains and balance the rotating assembly as well. While the three-week job turned into three months and about $900, it was money well spent, and here’s why.

Obviously the machine work on the block was a 100% necessity, but we made out good on some of the other items as well. Installing the cam bearings for one, requires special tools and a bit of experience to know when they’re in the right spot. The machine shop purchased and installed decent bearings for us for less than $40. Other work included decking the block, honing the lifter bores, installing upgraded ARP fasteners and chasing all the important threads on the block for pretty reasonable prices. But the most important lesson here for us was balancing.

I won’t get too far into this subject for now, as it’s more than a whole tech piece on its own, but the basic elements of the process involve equalizing the reciprocating forces (pistons and upper portion of the connecting rods) with the rotational forces (the crankshaft and the lower portion of the connecting rods). I’m definitely not an expert on the subject, but per the machine shop’s report on the final balance, our engine would not have been a happy one without some significant work here. We expected this, since our Scat rotating assembly was unbalanced, and the machine shop’s final results were 0.034 Oz-Inch on the left side and 0.062 Oz-Inch on the right side, numbers we were off from by a factor of about 250.

Moving forward on our engine is going to involve some pretty straightforward assembly from here, as far as pistons, rings, connecting rods, bearings and so on. But in the meantime, I really need to come up with a plan for finishing the rest of the engine. Our cubic inches are more or less set in stone now at 347 ci, but it’s the rest of the program that will really account for how the engine runs. We need to be thinking about a target compression ratio, power level and performance characteristics, which will largely be determined by the cylinder heads, camshaft and intake.

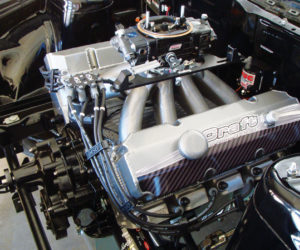

Cylinder heads are really my first order of business, as the combustion chamber size will determine the compression ratio, and the volume and finish of the runners will affect how the engine runs through the rpm range. Let me remind you that this engine will be going into a first-generation Bronco, so we’re really looking to tame this thing down a bit and aim for low-end torque. By the manufacturer’s information, our rotating assembly will result in a 10.1 compression ratio with a 64 cc chamber — generally the biggest chamber (lowest compression) you’ll find on a head except for some outliers. More aggressive chambers like the 58 and 54 cc versions would push this engine into the upper 10s and 11s, definitely not what we’re after in an early Bronco.

As far as intake runner volume goes (the general value for sizing heads), I had my heart set on something small. From my initial understanding, a smaller CNC-ported head will provide good low-end torque and drivability, while a port that’s too large for the engine will give up performance, especially on the bottom end. That would lead me to choose something small, like a 170, 185, or maybe a 190 at the most (these figures change slightly based on manufacturer). But I wasn’t sure how small was too small, so I called our friend Jim Woods at SBFBuilding.com for some advice. Jim insisted that we allocate as much of our budget to good heads as possible (always sound advice), and he suggested the Trick Flow Twisted Wedge 11R head, and I assume he meant the 170 CNC-ported 63 cc version. They’re pricey at right around $900 per side, but they’re CNC-ported and check the right boxes in my book. The only problem is that we can’t get them — literally no one has them right now.

I’ve been looking into other options but haven’t found anything seems right yet. AFR makes a new budget-minded head called the Enforcer, but it only comes with 58 cc chambers, and their other CNC-ported heads are way pricier. I know I could go a different direction and buy some refurbished GT40 iron heads for cheap, and I think the chamber size is right about where I want to be. But I know we’d be giving up a lot of power based on the intake runner volume, and likely the quality of the casting as well.

Anyway, that’s my challenge right now and I have to get something on order soon or we’ll never wrap this thing up. Since I’m sure you know more about heads than I do, please reveal your killer combos in the comments below.

Comments for: RCN Windsor Build Part 6

comments powered by Disqus